Closed punching method for GH4169 alloy high-cylinder ring part

A GH4169, alloy technology, applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., to achieve the effect of reducing operation difficulty, improving appearance quality, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The main chemical element content (weight percentage) of the GH4169 alloy is: C content ≤0.08%, Cr content 17.0%-21.0%, Ni content 50.0%-55.0%, Co content ≤1.0%, Mo content 2.80 %~3.30%, Al content 0.30%~0.70%, Ti content 0.75%~1.15%, Nb content 4.75%~5.50%, B content≤0.006%, Mg content≤0.01%, Mn content≤ 0.35%, Si content ≤ 0.35%, P content ≤ 0.015%, S content ≤ 0.015%, Cu content ≤ 0.30%, Ca content ≤ 0.01%, Pb content ≤ 0.0005%, Se content ≤ 0.0003 %, the balance is Fe.

[0016] The steps of this method are as follows:

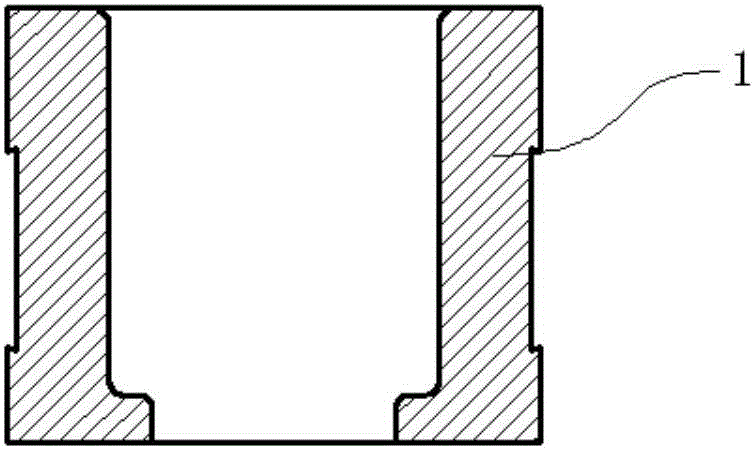

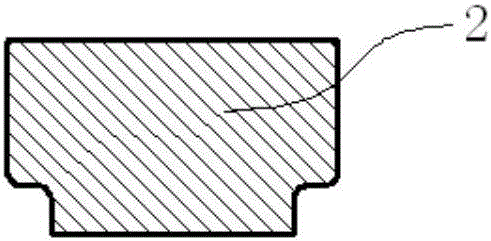

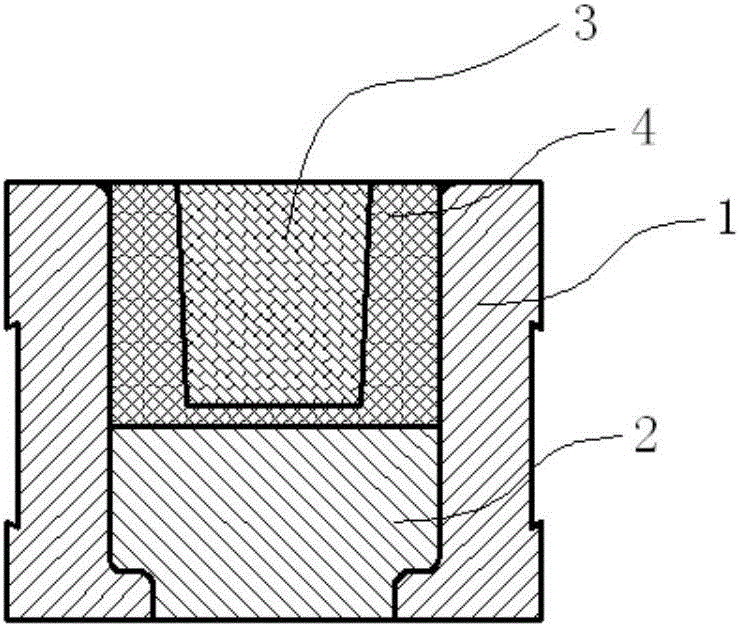

[0017] Cut the GH4169 alloy into bars according to certain specifications; heat the GH4169 alloy bars to 1050±10°C for heat preservation, and the furnace temperature ≤750°C; after the heat is through, place the GH4169 alloy bars on the press and drive the forging hammer Upsetting the GH4169 alloy bar to a predetermined size; put the upsetting GH4169 alloy blank 4 into the punching die 1 and put them together under the press. The outer wall of the punchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com