A flotation regulator applied to the separation and flotation of copper-molybdenum sulfide ore and its application method

A technology for adjusting agent and sulfide ore, applied in flotation, solid separation and other directions, can solve problems such as rising production costs, and achieve the effects of improving grade, fast copper suppression effect, and obvious copper suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

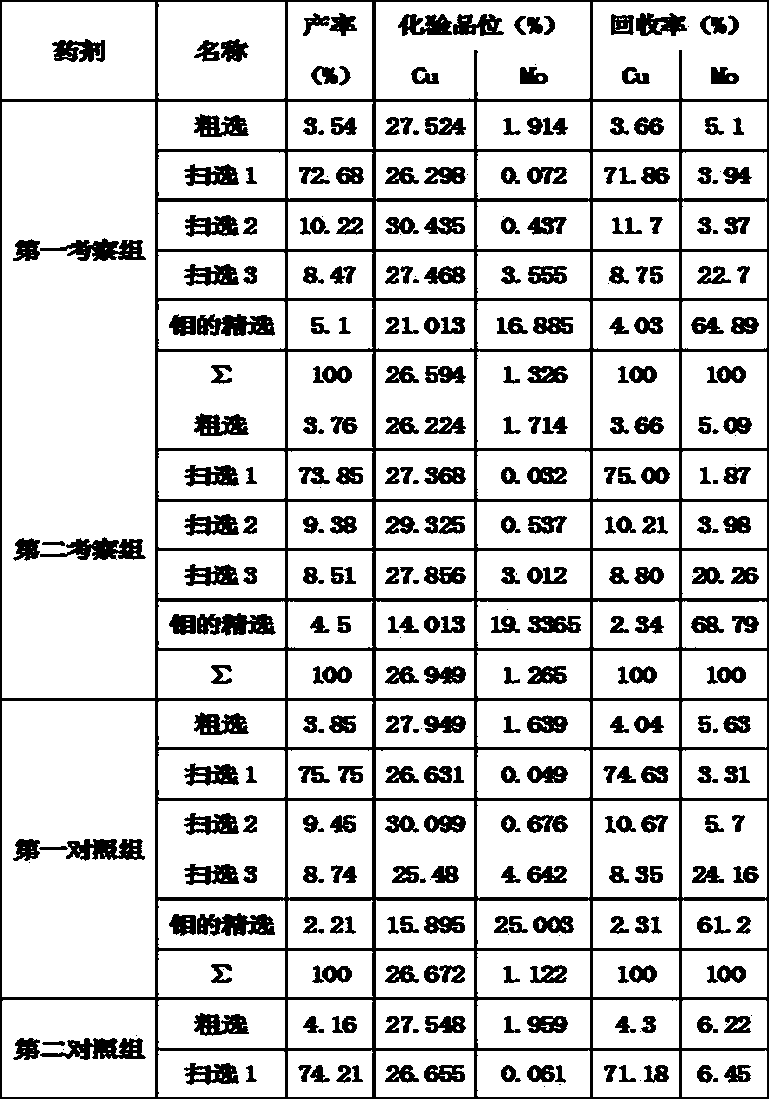

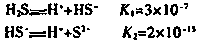

[0031] The same copper-molybdenum sulfide ore is divided into four groups of equal quality: the first investigation group, the second investigation group, the first control group, and the second control group for beneficiation. The beneficiation process includes 1 roughing and 3 sweeping. , One time molybdenum beneficiation, the reagents used in each beneficiation process include flotation regulators, collectors and foaming agents. In addition to flotation regulators, four groups of minerals are In the selection process, the same collector and foaming agent are used in the same amount. In different beneficiation stages, the four groups of minerals each use the same constant flotation regulator. The method of use is to first combine the minerals with the foaming agent, The collector was mixed, and then the flotation regulator was added for flotation; the flotation regulator used by the first investigation group was a mixture of sodium sulfide and drinking water, and the concentra...

Embodiment 2

[0036] The same copper-molybdenum sulfide ore as in Example 1 is used as the raw material, and the beneficiation process of 1 roughing, 3 sweeping, and 1 molybdenum beneficiation is also adopted. The reagents used for each beneficiation include flotation regulators and traps. Collector and foaming agent, the used collector and foaming agent and their dosage are the same as in Example 1. The beneficiation method is to first mix the mineral with foaming agent and collector, and then add flotation adjustment The flotation regulator is a mixture of sodium sulfide and drinking water. The concentration of sodium sulfide in the flotation regulator used in rough selection is 8~10wt%, and the concentration of sodium sulfide in the flotation regulator used in sweep selection 5~7wt%, the concentration of sodium sulfide in the flotation regulator used in the beneficiation is 5~8wt%, and the amount of flotation regulator is 15g per kilogram of mineral; after the above process After benefici...

Embodiment 3

[0038] The same copper-molybdenum sulfide ore as in Example 1 is used as the raw material, and the beneficiation process of 1 roughing, 3 sweeping, and 1 molybdenum beneficiation is also adopted. Collector and foaming agent, the used collector and foaming agent and their amounts are the same as in Example 1. The beneficiation method is to first mix the mineral with foaming agent and collector, and then add the electrified Flotation regulator. The flotation regulator is a mixture of sodium sulfide and drinking water. The concentration of sodium sulfide in the flotation regulator used in rough selection is 8-10wt%, and it is vulcanized in the flotation regulator used in sweeping The concentration of sodium is 5~7wt%, and the concentration of sodium sulfide in the flotation regulator used in the beneficiation is 5~8wt%. The flotation regulator used in the rough selection should be at a voltage of 1.2~1.6V before use Power on for 0.5~1h, the flotation regulator used for scanning sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com