Preparation and application of a flotation inhibitor for the separation of copper-molybdenum sulfide ore

A copper molybdenum sulfide and inhibitor technology, which is applied in flotation, solid separation and other directions, can solve the problems of increased production cost, high synthesis cost, insoluble products in water, etc., and achieves low production cost, good effect, and copper suppression effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

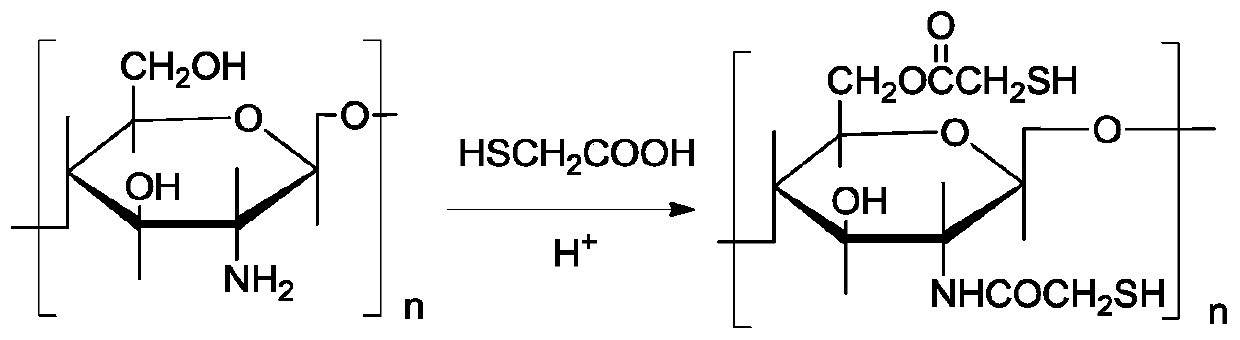

[0021] The preparation and application of the flotation inhibitor for the separation of copper-molybdenum sulfide ore of the present invention is characterized in that the preparation steps of the flotation inhibitor for the separation of copper-molybdenum concentrate are as follows: a certain amount of chitosan is weighed and added to a certain amount of thioglycolic acid , stirred and dissolved, then added to a certain amount of concentrated sulfuric acid, stirred and reacted for a certain period of time at room temperature, and the inhibitor product was obtained.

[0022] The degree of deacetylation of the chitosan is greater than or equal to 70%.

[0023] The mass ratio of the chitosan to the thiol reagent in the method of the invention is 1:10-20.

[0024] The concentrated sulfuric acid in the method of the present invention is 0.5-1.0% of the total mass.

[0025] The stirring time in the method of the present invention is 5-12 hours.

[0026] The flotation inhibitor de...

Embodiment 1

[0031] (1) Preparation of mercapto-chitosan: Weigh 10 g of chitosan with a degree of deacetylation of 70%, add it to 100 g of thioglycolic acid and 1 g of concentrated sulfuric acid, and stir at room temperature for 12 hours to obtain a mercapto-chitosan mixture.

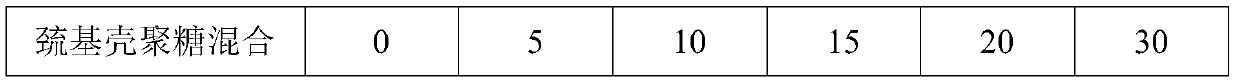

[0032] (2) The copper-molybdenum separation flotation inhibitor prepared by the present invention is subjected to a single mineral flotation experiment to verify its effect of suppressing copper and floating molybdenum. Add 200g of molybdenite and 200g of chalcopyrite to 3000mL of distilled water, adjust the pH to 9.5 with lime slurry, add the mercapto-chitosan mixture prepared in step (1) with different concentrations in turn, stir for 5min, add 70mg of kerosene, and stir for 5min , add 20mg of terpineol oil, stir for 5 minutes; scrape and foam for 5 minutes, the foam and tailings products are collected, dried and weighed to calculate the recovery rate. See Table 1 and Table 2 for the comparative results of sodium ...

Embodiment 2

[0047] (1) Preparation of mercapto-chitosan: 5 g of chitosan with a degree of deacetylation of 80% was weighed, added to 100 g of thioglycolic acid and 0.5 g of concentrated sulfuric acid, and stirred at room temperature for 5 hours to obtain a mercapto-chitosan mixture.

[0048] (2) The copper-molybdenum separation flotation inhibitor prepared by the present invention is subjected to a single mineral flotation experiment to verify its effect of suppressing copper and floating molybdenum. 200g molybdenite and 200g chalcopyrite were added to 3000mL distilled water respectively, the pH was adjusted to 10.5 with lime slurry, the mercaptochitosan prepared in step (1) of different concentrations were added successively, stirred for 5min, 70mg of kerosene was added, stirred for 5min, Add 20 mg of terpineol oil, stir for 5 minutes; scrape and soak for 5 minutes, and the foam and tailings products are collected, dried and weighed to calculate the recovery rate. See Table 5 and Table 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com