Method for treating waste gases in production of pomegranate peel extract

A technology of pomegranate peel extract and processing method, which is applied in the directions of gas treatment, separation method, chemical instrument and method, can solve problems such as unsatisfactory effect, etc., and achieve the effect of obvious effect, cost saving and shortening process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

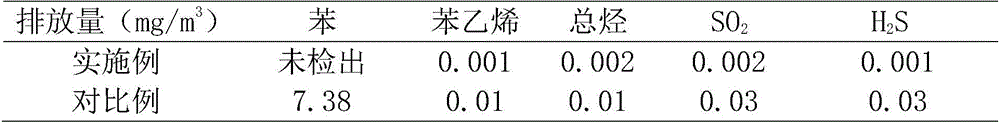

Examples

Embodiment 1

[0026] The processing method of waste gas in the production of pomegranate peel extract comprises the steps:

[0027] 1) Spray tower absorption: the waste gas generated during production is concentrated and then enters the spray tower for treatment;

[0028] The spray tower is two stages connected in series. The two-stage spray tower is equipped with fillers. The liquid phase substance in the spray tower is water. The two-stage spray tower plays a protective role and is connected with the subsequent process treatment;

[0029] 2) The processed gas is transported through pipelines to the chimney in the factory for high-altitude discharge;

[0030] Described filler is prepared by the following method:

[0031] a. Raw material preparation: prepare fiber silk and mango peel according to the weight ratio of 90:10;

[0032] b. Processing of mango peel:

[0033] ① Enzyme hydrolysis treatment: add pure water equivalent to 2-3 weight of mango peel after crushing or crushing, heat to...

Embodiment 2

[0038]The processing method of waste gas in the production of pomegranate peel extract comprises the steps:

[0039] 1) Spray tower absorption: the waste gas generated during production is concentrated and then enters the spray tower for treatment;

[0040] The spray tower is two stages connected in series. The two-stage spray tower is equipped with fillers. The liquid phase substance in the spray tower is water. The two-stage spray tower plays a protective role and is connected with the subsequent process treatment;

[0041] 2) The processed gas is transported through pipelines to the chimney in the factory for high-altitude discharge;

[0042] Described filler is prepared by the following method:

[0043] a. Raw material preparation: prepare fiber silk and mango peel according to the weight ratio of 92:8;

[0044] b. Processing of mango peel:

[0045] ① Enzyme hydrolysis treatment: add pure water equivalent to 2-3 weight of mango peel after crushing or crushing, heat to 6...

Embodiment 3

[0050] The processing method of waste gas in the production of pomegranate peel extract comprises the steps:

[0051] 1) Spray tower absorption: the waste gas generated during production is concentrated and then enters the spray tower for treatment;

[0052] The spray tower is two stages connected in series. The two-stage spray tower is equipped with fillers. The liquid phase substance in the spray tower is water. The two-stage spray tower plays a protective role and is connected with the subsequent process treatment;

[0053] 2) The processed gas is transported through pipelines to the chimney in the factory for high-altitude discharge;

[0054] Described filler is prepared by the following method:

[0055] a. Raw material preparation: prepare fiber silk and mango peel according to the weight ratio of 95:5;

[0056] b. Processing of mango peel:

[0057] ①Enzymolysis treatment: add pure water equivalent to 2-3 weight of mango peel after crushing or crushing, heat to 55°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com