Cyclone separating type gas-liquid mixed phase feeding distributor

A technology of feed distributor and rotary split type, which is applied in the field of separation towers and can solve the problems of reducing the pressure drop of the feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

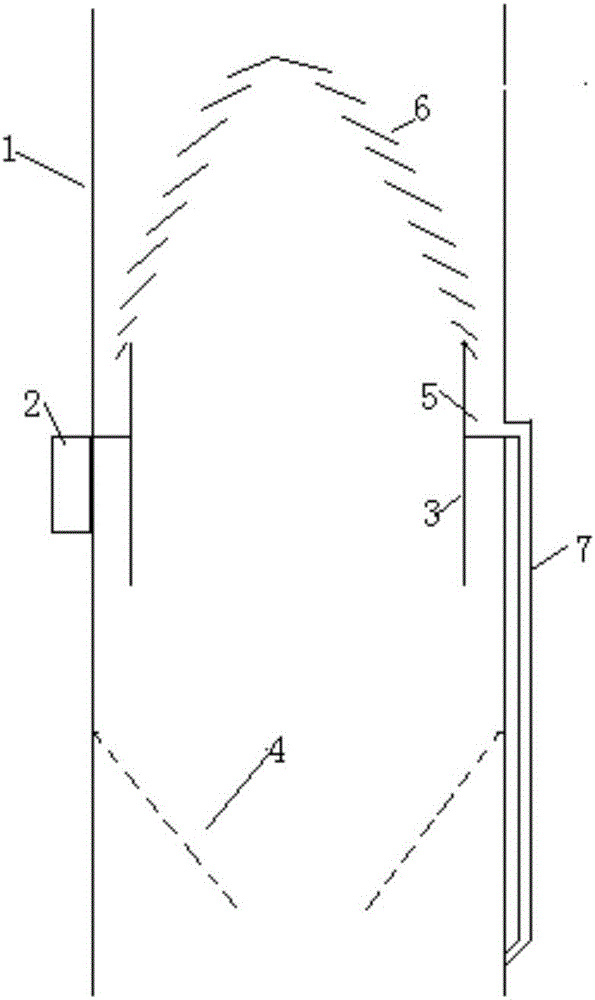

[0022] A spin-splitting gas-liquid mixed-phase feed distributor is integrated by the following structure: the gas-liquid mixed-phase feed inlet (2) is a rectangular feeding structure in the tangential direction, and the ratio of height to width is 2-15:1. The inner annular sleeve (3) of the body (1) is connected; the lower end of the annular sleeve (3) is open, and the annular cross-sectional area accounts for 5%-80% of the cross-section of the tower, and the annular sleeve (3) is along the inner wall from top to bottom. It is a cylindrical or conical structure; the distance from the lower end of the annular sleeve (3) is 0.8-3 times the height of the feed inlet (2) and the tower wall is provided with a conical funnel (4) with a hole in the plate surface, and the cone angle is 10°- 90°, the diameter of the cone opening of the funnel (4) is 0.1-1.5 times the width of the feed inlet (2); the middle part of the annular sleeve (3) is closed to form an annular oil collection tank (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com