Physical antibacterial wet wipe

A wet wipe, physical technology, applied in physical treatment, topical antibacterial agent, drug combination and other directions, can solve the problem of easy precipitation of preservatives and irritation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0046] 1) Reaction of octadecyl dimethyl tertiary amine with epichlorohydrin and hydrochloric acid:

[0047] The dry hydrogen chloride gas was introduced into the anhydrous ether solution of octadecyldimethyl tertiary amine to produce white precipitate. Then use water as the solvent, put a certain amount of epichlorohydrin in the dropping funnel, start to drop it slowly, drop it in 35 minutes, stir evenly at room temperature, react at 80°C for 12h, and titrate the epichlorohydrin quaternary ammonium After the reaction was completed, the solvent was removed by rotary evaporation at room temperature to obtain a light yellow paste residue, which was recrystallized with acetone, filtered under reduced pressure after the crystals were precipitated, and repeated several times. Obtain white powder single quaternary ammonium salt product---intermediate product N-(3-chloro-2-hydroxypropyl)-N,N-dimethyl octadecyl ammonium chloride.

[0048]

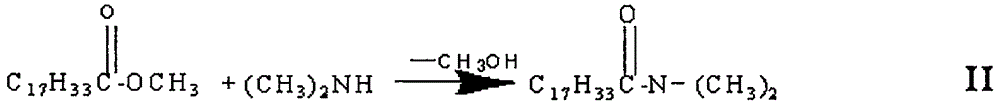

[0049] 2) Reaction process: Methyl oleat...

preparation example 2

[0057] Same as Preparation Example 1, the only difference is that in the 1) step, anhydrous diethyl ether solution of dodecyldimethyl tertiary amine is used to finally obtain 2-triethoxysilyl propaneoxy-1-N,N -Dimethyloleoyl-3-dodecyldimethylammonium propane dichloride (abbreviation: organosilicon bisquaternary ammonium salt B), the yield is 98.5%.

[0058]

Embodiment 1

[0060] The preparation method of the wet wipe body is as follows:

[0061] (1) Using bamboo pulp fibers with a length of 40mm and a diameter of 0.08mm as raw materials, a bamboo pulp non-woven fabric is obtained after cross-lapping and spunlace technology, and a non-woven fabric carrier with a thickness of 3mm is obtained after cutting and high-temperature sterilization ;

[0062] (2) Place the non-woven fabric carrier prepared in step (1) in the monomer solution configured by isopropanol / water mixed solvent, and soak it in the dark at room temperature for 24 hours, wherein the mass of the monomer in the monomer solution The fraction is 0.5%, and the volume ratio of isopropanol to water is 3:1;

[0063] (3) Under the protection of nitrogen, irradiate the non-woven fabric obtained after soaking in the above step (2) with gamma rays, and the irradiation intensity is 200KGy;

[0064] (4) After the irradiation is finished, unreacted monomers and homopolymers are extracted and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com