Magnetic snap connected rotary slide block self-locking lifting side shaft edge drum mop cleaning and spin-drying machine

A mop cleaning and rotating shaft technology, which is applied in the field of daily necessities, can solve the problem that mop cleaning and drying cannot be completed at one time, and achieve the effect of convenient and fast cleaning, easy operation, and improved drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

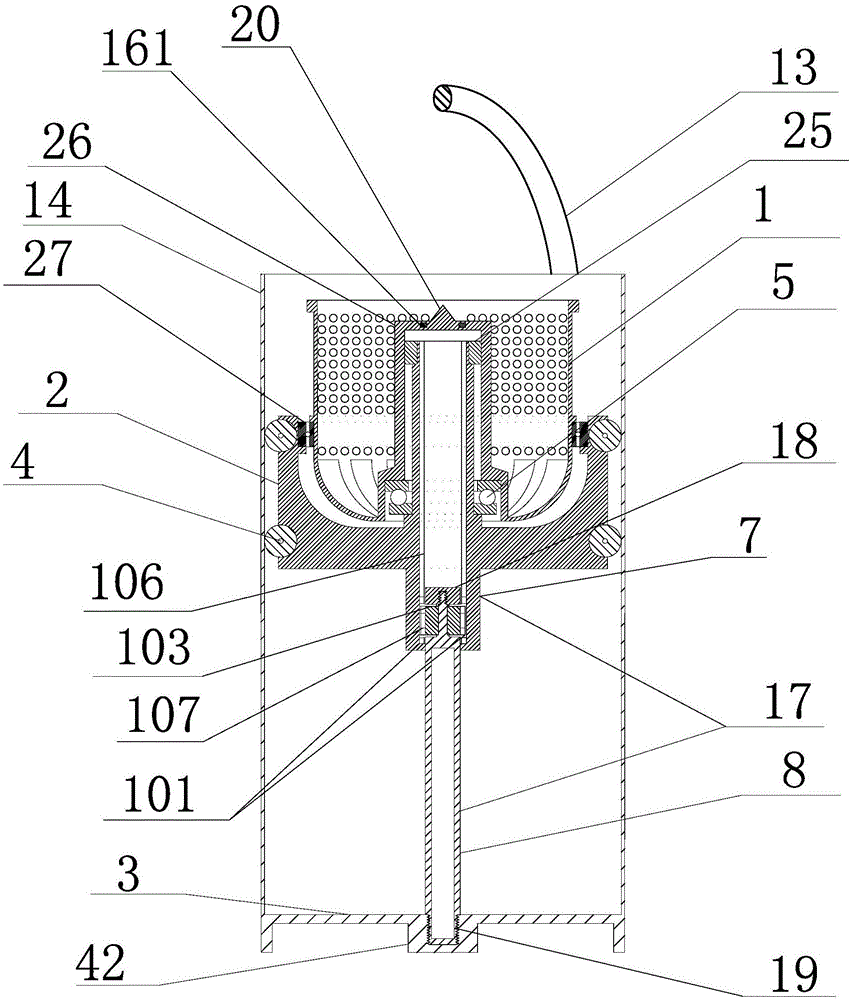

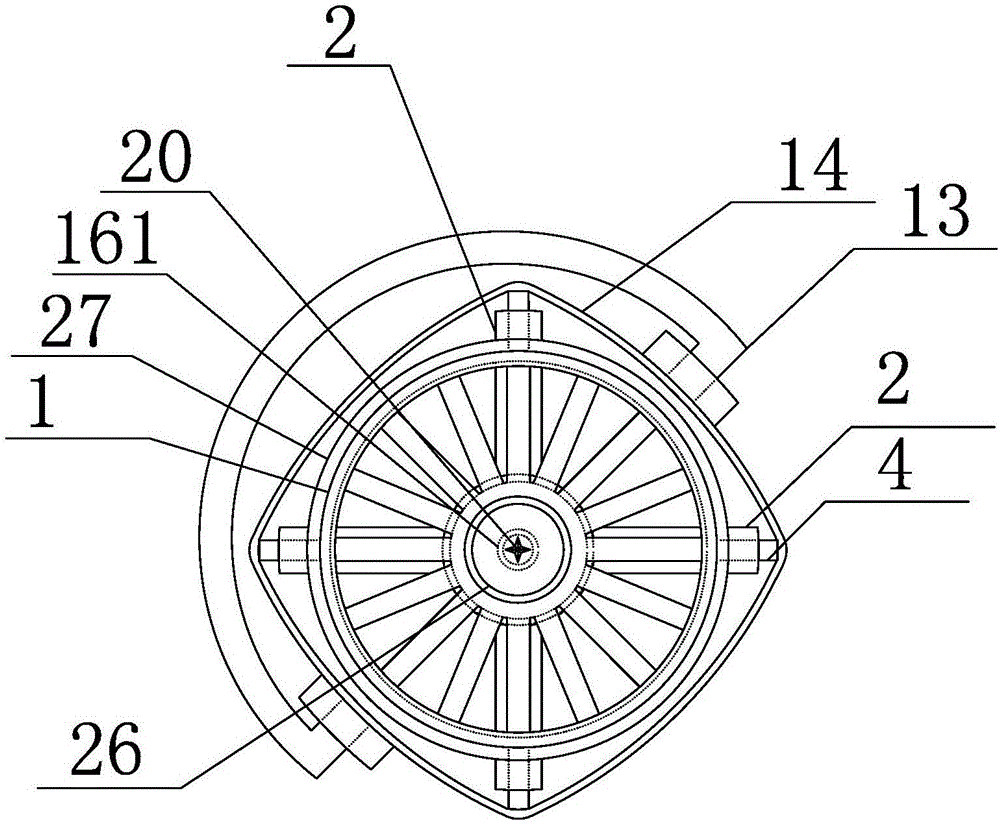

[0029] Figure 1-Figure 17 In the embodiment, a magnetic buckle is connected with a rotating slider to self-lock and lift the side shaft and the edge cylinder mop cleaning and drying device. The cleaning bucket (14) is provided with a rotating basket (1), and the rotating basket (1) and the cleaning bucket (14) There is a rotating basket bracket (2) between them, and the rotating basket bracket (2) is connected with the rotating basket (1) and the cleaning bucket (14). The shaft group (17), the rotating basket lifting shaft group (17) is composed of a hollow upper rotating shaft (7) and a lower rotating shaft (8), and the lower end of the lower rotating shaft (8) is provided with a lower rotating shaft and a lower shaft head (19), the lower shaft head (19) of the lower rotating shaft is fixedly connected with the lower shaft head hole (42) of the lower rotating shaft at the center of the barrel (3), and it is characterized in that: set the rotating basket lifting shaft group (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com