Steaming box equipment capable of being automatically sent out

A steamer, automatic technology, applied in steam cooking utensils, cooking utensils, household utensils, etc., can solve the problems of unstable force, inability to meet various needs, and delaying the speed of food delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

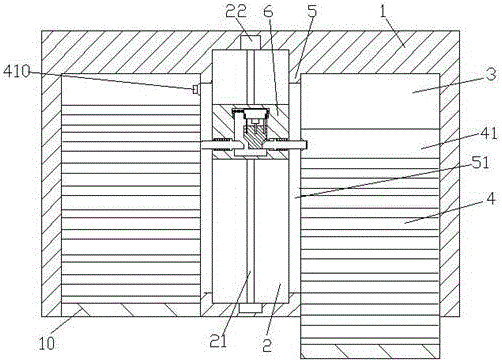

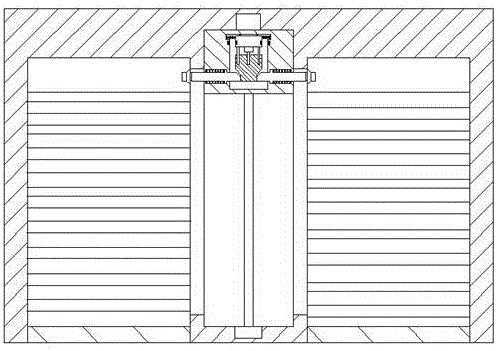

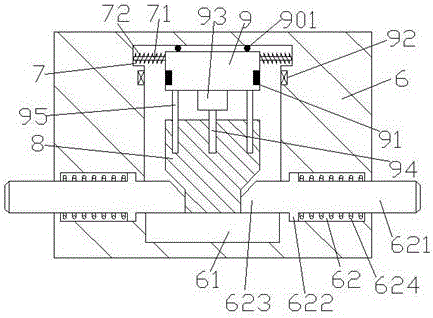

[0018] Such as Figure 1-Figure 5 As shown, a steam box device capable of automatic delivery of the present invention includes a box body 1 in which cavities 3 and sliding cavities 2 arranged between the cavities 3 are symmetrically arranged on the left and right sides. A baffle plate 5 with a rail groove 51 is provided between the sliding cavity 2 and the cavity 3. The cavity 3 is provided with a holding plate 4, and the rear surface of the holding plate 4 is provided with a straight plate 41, so The sliding cavity 2 is provided with a No. 1 screw rod 21, the No. 1 screw rod 21 is threaded with a manipulation part 6, the manipulation part 6 is provided with a manipulation chamber 61, and the top ends of the manipulation chamber 61 are provided with The placement groove 7 is arranged oppositely. The placement groove 7 is provided with a No. 1 guide rod 71, and the No. 1 guide rod 71 is provided with a straight part 9 for sliding left and right joints. An upper compression elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com