Manufacturing method of bean curd

A production method and tofu technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problem of low quality tofu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

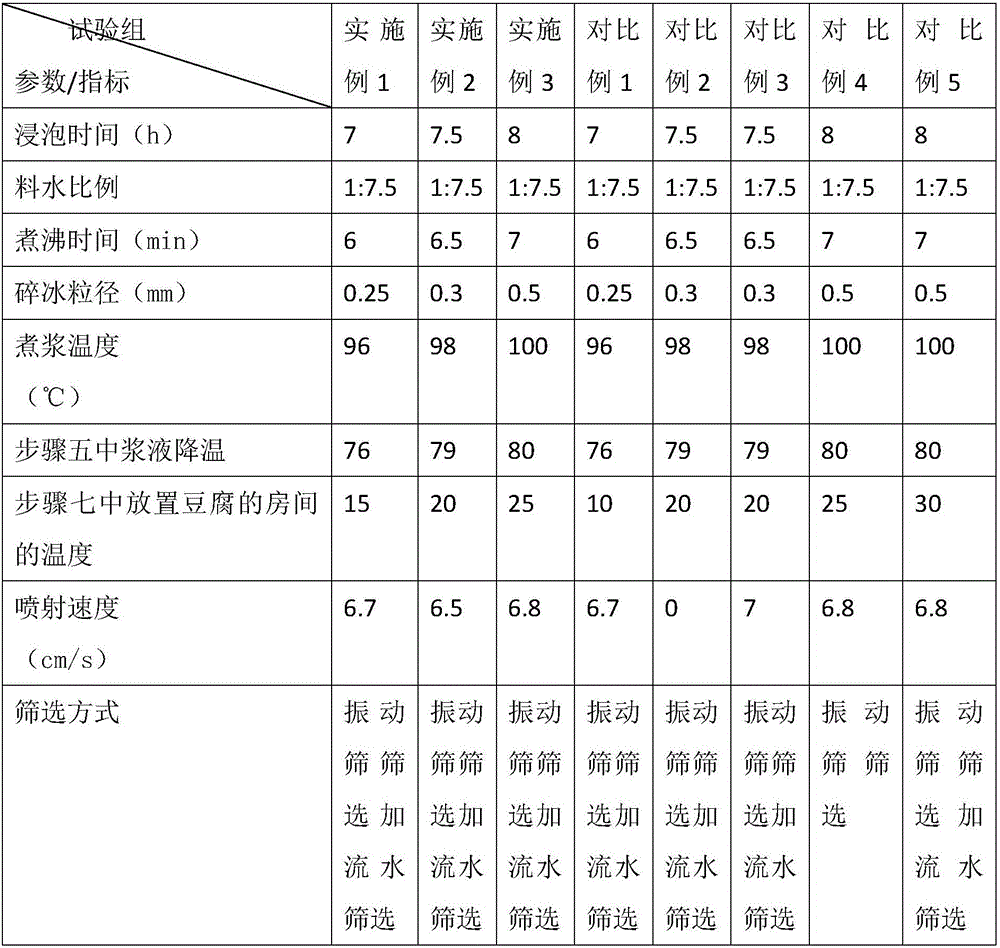

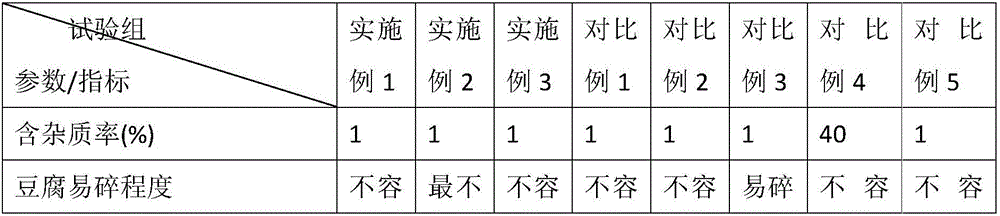

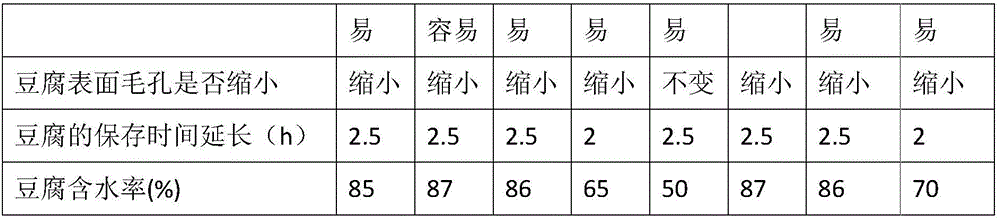

[0039] Comparing Example 1 with Comparative Example 1, it can be seen that when the temperature of the room where the tofu is placed in step 7 is lower than 15°C, the ice cubes are not easy to melt due to the low temperature in the room, and the freshly made tofu itself is placed at a lower temperature. When the room is low, the pores of the tofu itself will shrink to a certain extent. At this time, spray ice on the surface, and the crushed ice will not easily enter the pores on the surface of the tofu, so there will be less crushed ice in the pores on the surface. At this time, the water It is not easy to immerse into the inside of the tofu, so its water content does not increase significantly; and because there are fewer crushed ice in the pores on the surface of the tofu, its storage time is relatively less extended.

Embodiment 2

[0040] Compared with Comparative Example 2, it can be seen that when the speed of spraying crushed ice to the tofu in Example 2 is 6.5cm / s, the tofu is not easy to damage, and the water content is the highest; At this time, the moisture content of the tofu is significantly lower than that sprayed with crushed ice before, and the pores on the surface of the tofu have not shrunk.

Embodiment 3

[0041] Comparing Example 3 with Comparative Example 5, it can be seen that when the temperature of the room where the tofu is placed in step 7 is higher than 25°C, when the crushed ice is sprayed on the surface of the tofu, due to the indoor temperature, the fusion is relatively slow. Fast, at this time, when the pores shrink, there will be less ice wrapped in the pores, and less water will be immersed in the tofu, so it will also affect the increase of the moisture content of the tofu; in addition, when the tofu shrinks, the ice inside Less, and its preservation time is relatively less extended.

[0042] Comparing Example 2 with Comparative Example 3, it can be seen that when the jet velocity of the crushed ice is greater than 6.8 cm / s, the tofu is easily broken by the ice.

[0043] Comparing Example 3 with Comparative Example 4, it can be seen that only one screening by vibrating sieve is used, and the impurity rate of the screened soybeans is relatively large, and the scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com