Fermented milk containing fruit and vegetable particles and preparation method thereof

A technology of fruit and vegetable granules and fermented milk, which is applied in the direction of bacteria and lactobacillus used in dairy products and food preparation, which can solve the problems of excessive loss of active ingredients, high sugar content of fruit and vegetable granules, and unfavorable human health. The method is simple, the heat treatment is reduced, and the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of fermented milk base:

[0030] Get fresh milk (protein content is 2.8wt%, fat is 3.5wt%, carbohydrate is 4wt%, titrated acidity is 17 ° T), preheats to 50 ℃, adds white granulated sugar, milk protein concentrate and purified water, adds The ratio is shown in Table 1:

[0031] Ingredients Amount added% fresh milk 85 White sugar 7 milk protein fortifier 0.1 pure water 7.9

[0032] When mixing materials, stir at 50°C for 7 minutes at a stirring rate of 300 rpm. Continue pasteurization, 72°C, 30s, cool to 8°C, fill into compound bags for aseptic packaging of liquid food, and store at 3°C

[0033] Liquid food is aseptically packaged in composite bags and the milk is subjected to ultra-high pressure treatment. The treatment condition is 300 MPa and the treatment time is 7 minutes. The fresh milk after treatment is temporarily stored in a sterile fermentation tank with a temperature of 40 °C.

[0034] The added starter...

Embodiment 2

[0040] 1. Preparation of fermented milk base:

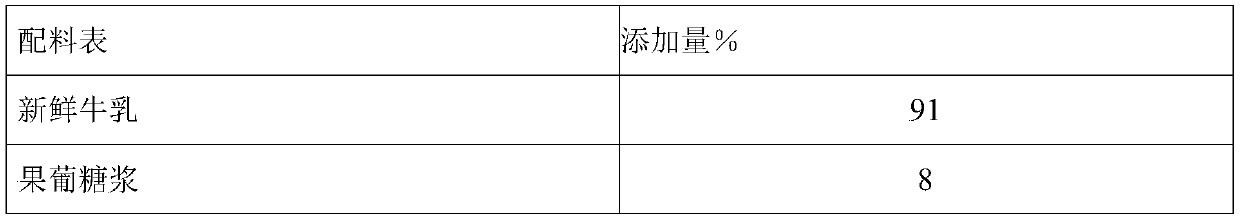

[0041] Get fresh milk (protein content is 3.5wt%, fat is 0wt%, carbohydrate is 6wt%, titrated acidity is 17 ° T), preheats to 60 ℃, adds fructose syrup, whey protein concentrate and purified water, The addition ratio is shown in Table 2:

[0042]

[0043]

[0044] When mixing, stir at 50° C. for 7 minutes at a stirring speed of 600 rpm. Continue pasteurization, 77°C, 15s, cool to 12°C, fill into compound bags for aseptic packaging of liquid food, and store at 5°C

[0045] Liquid food is aseptically packaged in composite bags and the milk is subjected to ultra-high pressure treatment. The treatment condition is 600 MPa and the treatment time is 3 minutes. After the treatment, the fresh milk is temporarily stored in a sterile fermentation tank with a temperature of 45 °C.

[0046]The added starter is a direct throw starter, including Streptococcus thermophilus and Lactobacillus bulgaricus, and the amount added is 2.5×10 8 ...

Embodiment 3

[0052] 1. Preparation of fermented milk base:

[0053] Get fresh milk (protein content is 3.0wt%, fat is 3wt%, carbohydrate is 5wt%, titrated acidity is 17 ° T), preheats to 55 ° C, adds white granulated sugar, glucose, casein powder and purified water, adds The ratio is shown in Table 3 below:

[0054] Ingredients Amount added% fresh milk 90 White sugar 2.5 glucose 5 casein powder 0.25 pure water 2.25

[0055] When mixing materials, stir at 55°C for 5 min at a stirring speed of 500 rpm. Continue pasteurization, 75°C, 20s, cool to 10°C, fill into compound bags for aseptic packaging of liquid food, and store at 4°C

[0056] Liquid food is aseptically packaged in composite bags and the milk is subjected to ultra-high pressure treatment. The treatment condition is 600 MPa and the treatment time is 3 minutes. After the treatment, the fresh milk is temporarily stored in a sterile fermentation tank with a temperature of 45 °C.

[0057]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com