Pneumatic straw deep-burying returning machine

A pneumatic straw technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of plow bottom layer thickening and upward movement, soil leakage and soil moisture, excess straw, etc., to reduce the number of times of entering the field, reduce The effect of machine energy consumption and economic cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

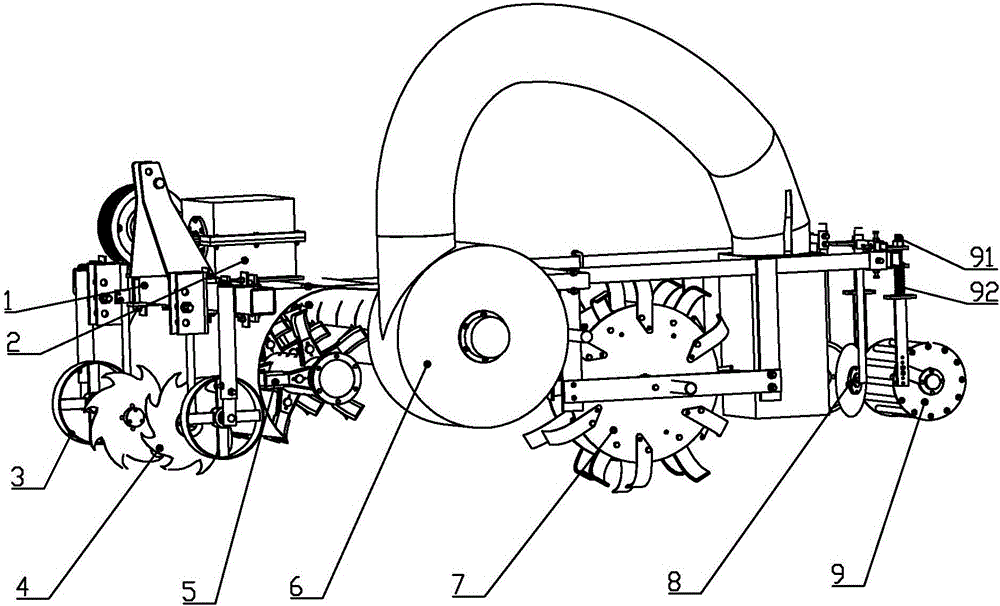

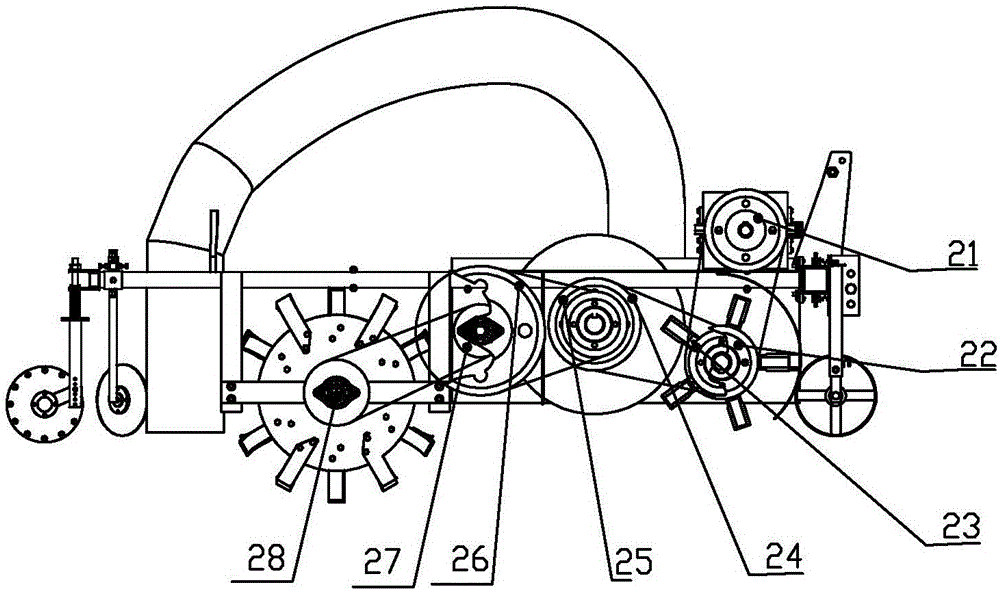

[0033] Embodiment 1: as Figure 1-Figure 2 Shown, the present invention comprises frame 1, transmission device 2 and is installed on this frame 1 and is installed on this frame 1 by the stubble breaking device 4 that advances to the rear end, picks up crushing device 5, conveying device 6, ditching device 7, soil covering device 8 and Repression device 9;

[0034] The stubble breaking disc of described stubble breaking device 4 is placed in the position of the ridge platform, and is used for breaking stubble; There are two stubble discs on the side;

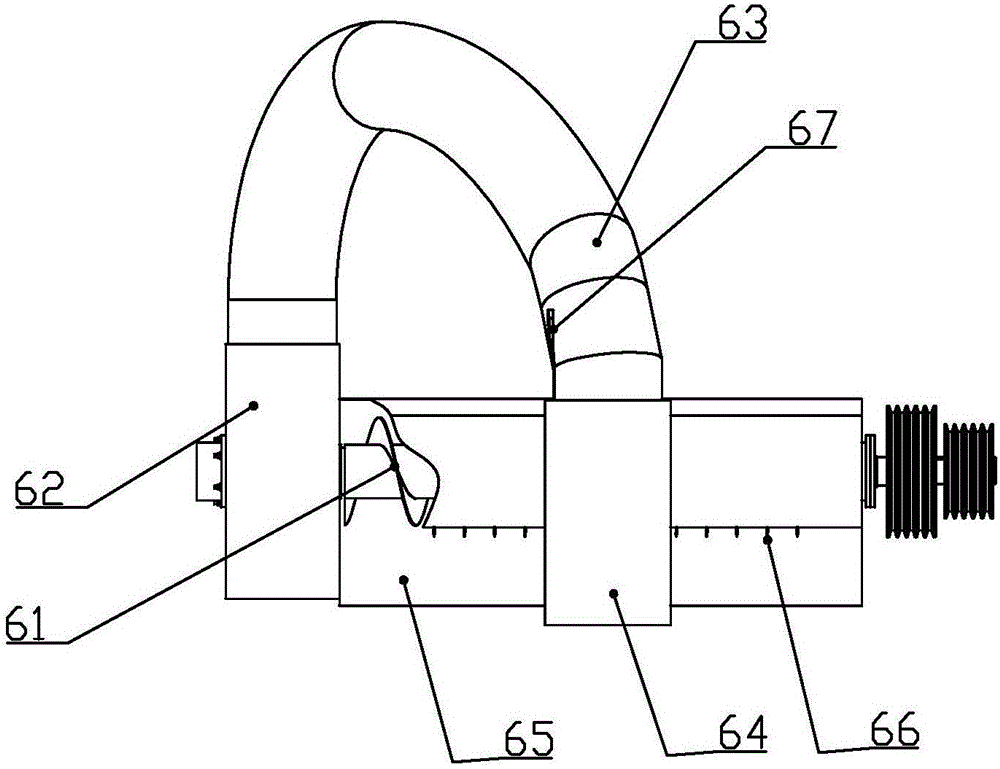

[0035] like Figure 4 As shown, the picking and crushing device 5 is an existing structure, which is connected to the casing 65 of the conveying device 6, and throws straw;

[0036] like Figure 3-Figure 5 As shown, the conveying device 6 is provided with a casing 65 at one end, through which the picking and crushing device 5 is connected to escort the crushed straw;

[0037] The conveying device 6 includes a casing 65, a bl...

Embodiment 2

[0049] Embodiment 2: The difference between this example and Embodiment 1 is that: the central angle of the casing and the matching end of the throwing knife shaft of the picking and crushing device in this example is α is 140°; the central angle of the matching end with the auger is 360°-β 270°, convey the crushed straw. The knife head gap H between the moving knife and the fixed knife is 60mm. The distance L between the knife throwing shaft of the picking and crushing device and the auger axis of the conveying device is 400-600 mm. The ditching device includes a ditching main shaft and two ditching cutter heads arranged symmetrically on the ditching main shaft, and the angle γ between the two ditching cutter heads is 10°.

Embodiment 3

[0050] Embodiment 3: The difference between this example and Embodiment 1 is that: the central angle of the casing and the matching end of the throwing knife shaft of the picking and crushing device in this example is α is 130°; the central angle of the matching end with the auger is 360°-β 260°, convey the crushed straw. The knife head gap H between the moving knife and the fixed knife is 50mm. The distance L between the knife throwing shaft of the picking and crushing device and the auger axis of the conveying device is 900 mm. The ditching device includes a ditching main shaft and two ditching cutter heads arranged symmetrically on the ditching main shaft, and the angle γ between the two ditching cutter heads is 8°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com