Inlet valve arrangement and method for external-heat engine

A technology for intake valves and engines, applied in variable displacement engines, reciprocating piston engines, valve devices, etc., can solve the problems of complex mechanical structure, space occupation, unreliable closing function of poppet valves, etc., and achieve good functional stability and wear resistance, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

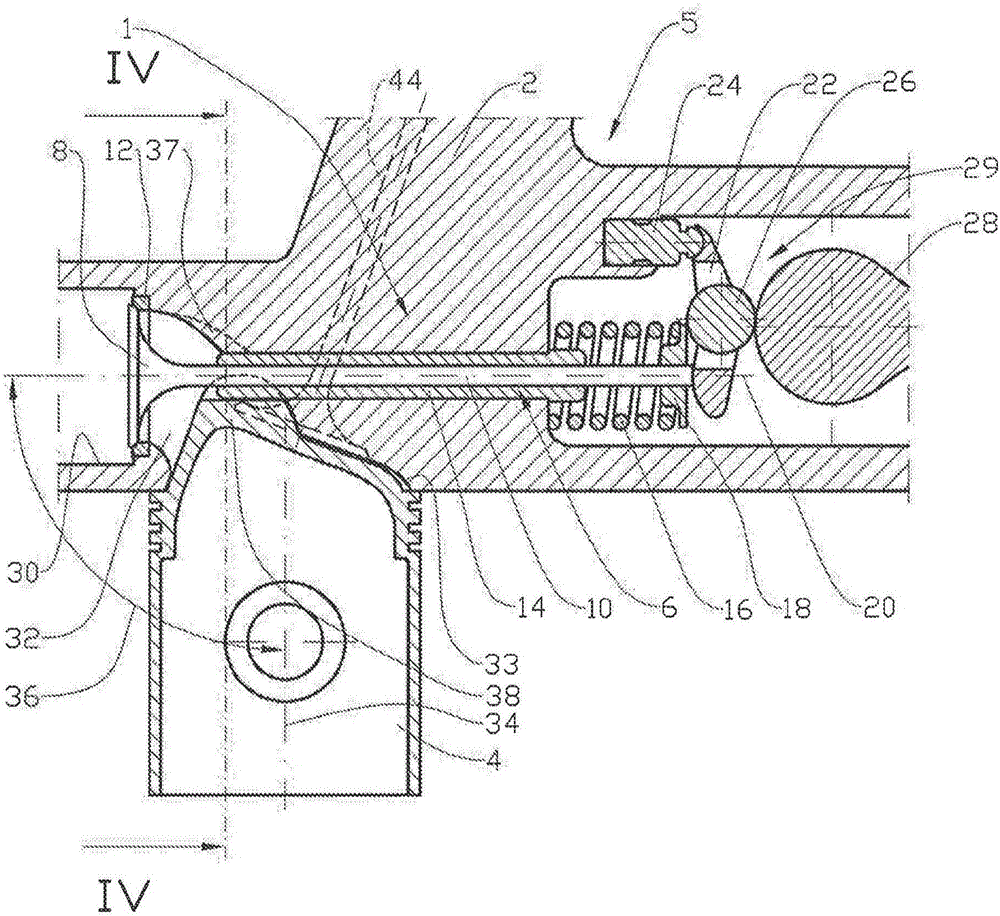

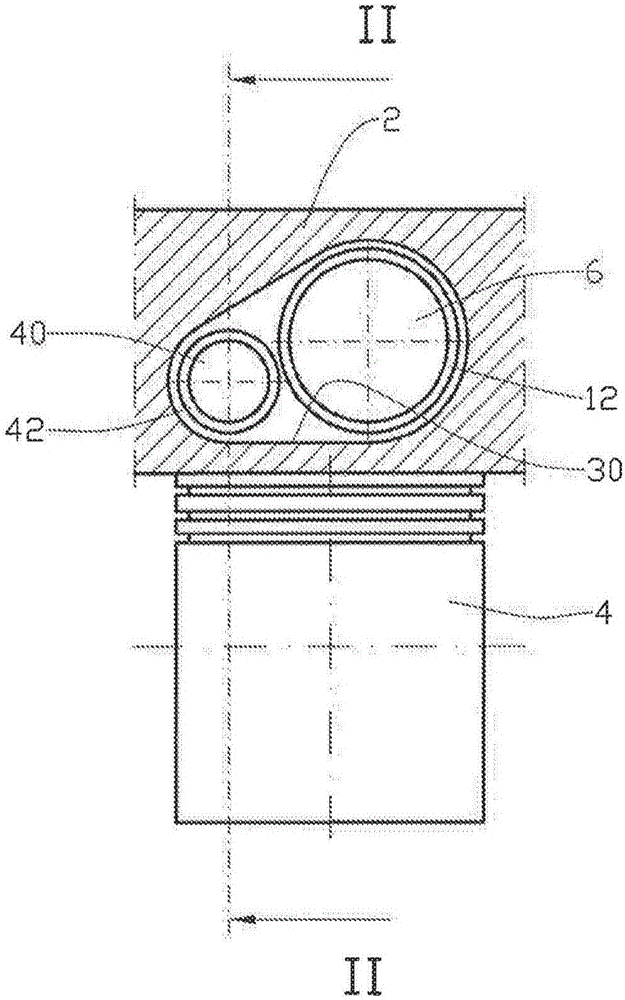

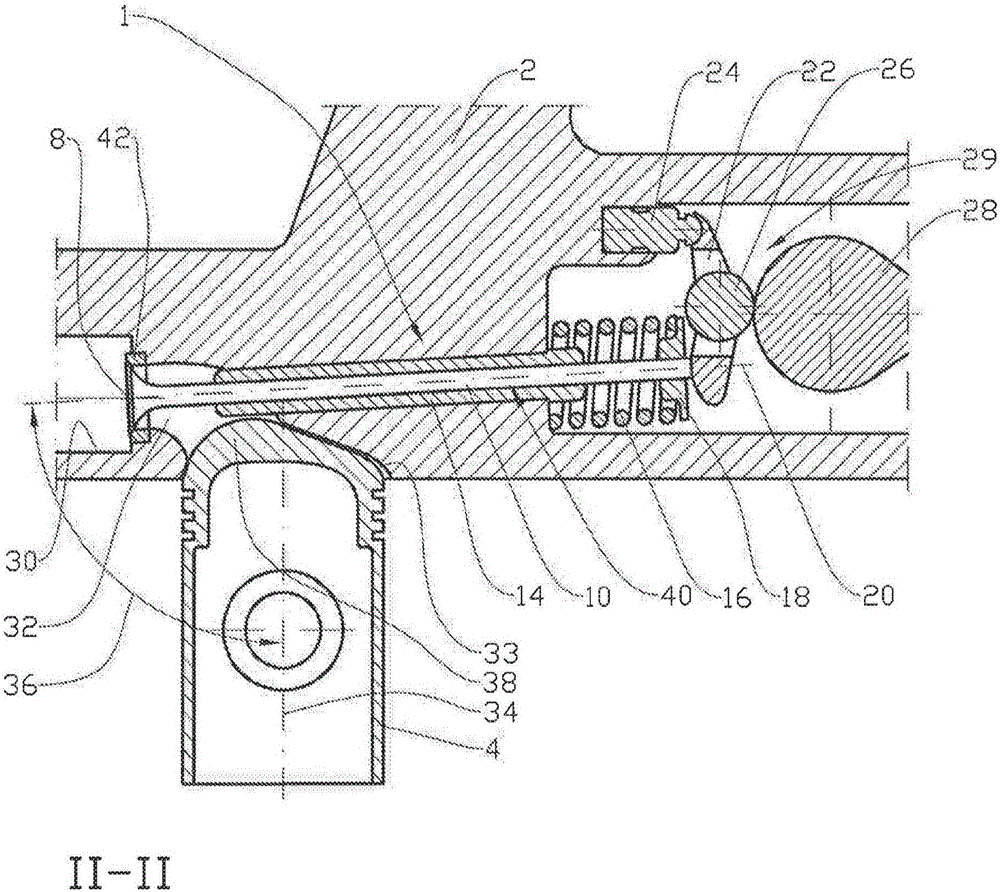

[0033] In the drawings, reference numeral 1 denotes an intake valve device located inside a cylinder head 2 . The piston 4 is shown, but the rest of those essential engine components forming part of the externally heated engine 5 are not shown. These components are known to those skilled in the art.

[0034] The intake valve arrangement 1 comprises a poppet valve 6 (its design is known per se) with a valve head (valve head) 8 and a valve stem 10, a valve seat 12, a valve guide 14 and a valve spring 16, the valve spring 16 being supported by a collar 18 is connected to the valve stem. Poppet valve 6 has a center axis 20 .

[0035] The rocker arm 22 is pivotably supported in a support piston 24 and is arranged to open the poppet valve 6 when a roller 26 within the rocker arm rests against a camshaft 28 . The components 22 to 28 constitute a valve actuator 29 .

[0036] The backing piston 24 is hydraulically operated and is arranged to maintain a desired clearance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com