High efficiency and energy-saving dual-axis groove type photovoltaic automatic tracking system

A high-efficiency, energy-saving, automatic tracking technology, applied in photovoltaic modules, photovoltaic power generation, photovoltaic module support structures, etc., can solve problems such as inability to use dual-axis tracking, aging accuracy of moving electrodes, structural limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the technical solutions of the present invention will be described in detail through specific embodiments.

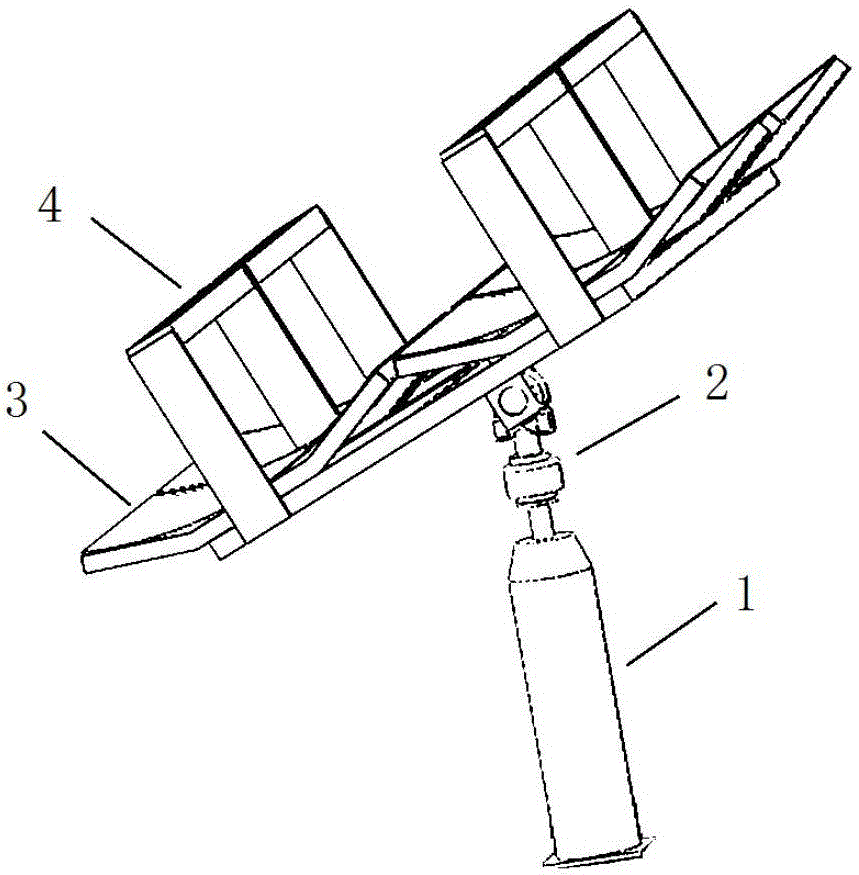

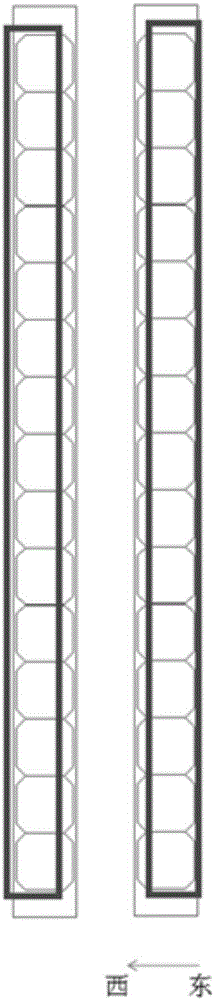

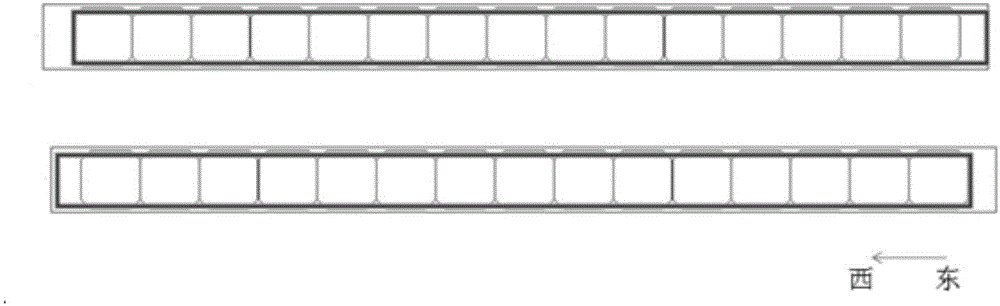

[0023] like Figure 1-4 shown, figure 1 It is a schematic structural diagram of a high-efficiency and energy-saving dual-axis slot-type photovoltaic automatic tracking system proposed by the present invention; figure 2 It is a schematic diagram corresponding to the light spot of the existing trough-type concentrator when the sun altitude angle changes during operation; image 3 It is a schematic diagram corresponding to the light spot of the tracking and concentrating cell when the sun altitude angle changes during the operation of the high-efficiency and energy-saving dual-axis slot-type photovoltaic automatic tracking system proposed by the present invention; Figure 4 It is a positional relationship diagram of the first concentrating plate and the second concentrating plate in the grooved concentrating plate in the high-efficiency and energy-sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com