Grinding wheel wear real-time compensation method based on numerical control system

A numerical control system and real-time compensation technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of unsuitable grinding and polishing of special-shaped contours, practical application limitations, high cost, etc., and achieve good consistency of polishing effect , less cost of equipment transformation, high grinding precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

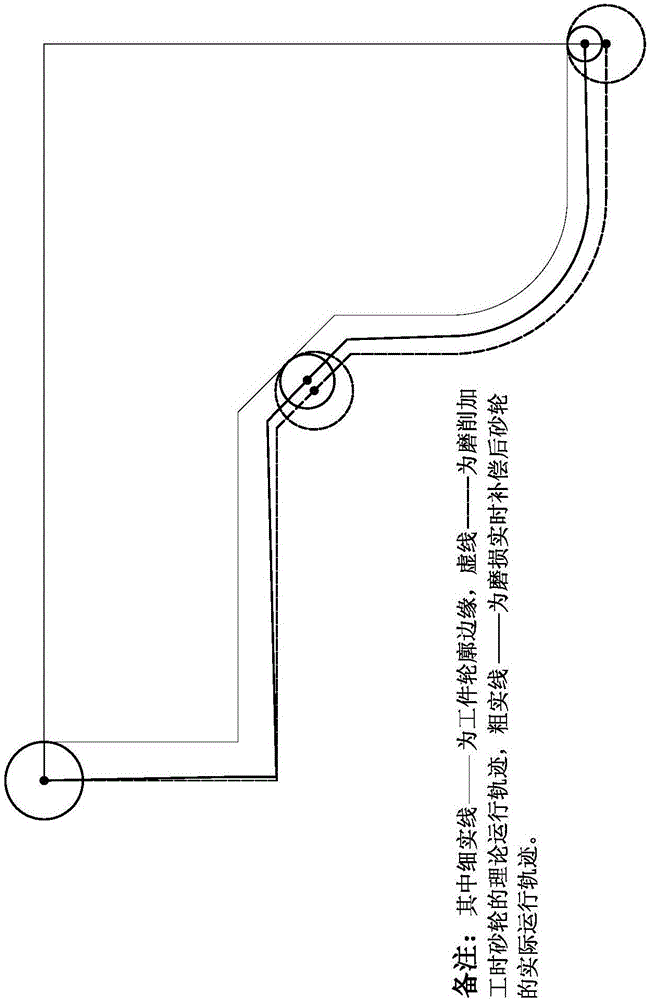

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be further described in conjunction with the secondary development and application of the real-time compensation of the Huazhong CNC 818A system. The present invention includes but is not limited to the following embodiments.

[0033] A kind of grinding wheel wear real-time compensation method based on numerical control system of the present invention, specifically comprises the following steps:

[0034] Step 1. Obtain the spindle motor current I from the frequency converter unit of the three-phase asynchronous motor at each sampling period T (T=1ms) i , i=1, 2, ..., k, ..., that is, the motor current I is obtained from the drive unit of the spindle motor i ;

[0035] Step 2. Connect the motor current Ii obtained in real time to the numerical control system through the analog input module HIO-1073;

[0036] Step 3, in the numerical control system, read the motor current I of each sampling cycle in real time i The weighted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com