Loose Tube Low Viscosity Fiber Paste Filling Technology

A loose-tube, low-viscosity technology, applied in the direction of fiber mechanical structure, instrumentation, optics, etc., can solve the problem that the filling volume of low-viscosity fiber paste is difficult to control and adjust, the outer diameter of the loose tube fluctuates greatly, and the support of the oil gun is difficult to adjust Moderate problems, achieve the effect of improving fiber paste filling technology, improving bulging situation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

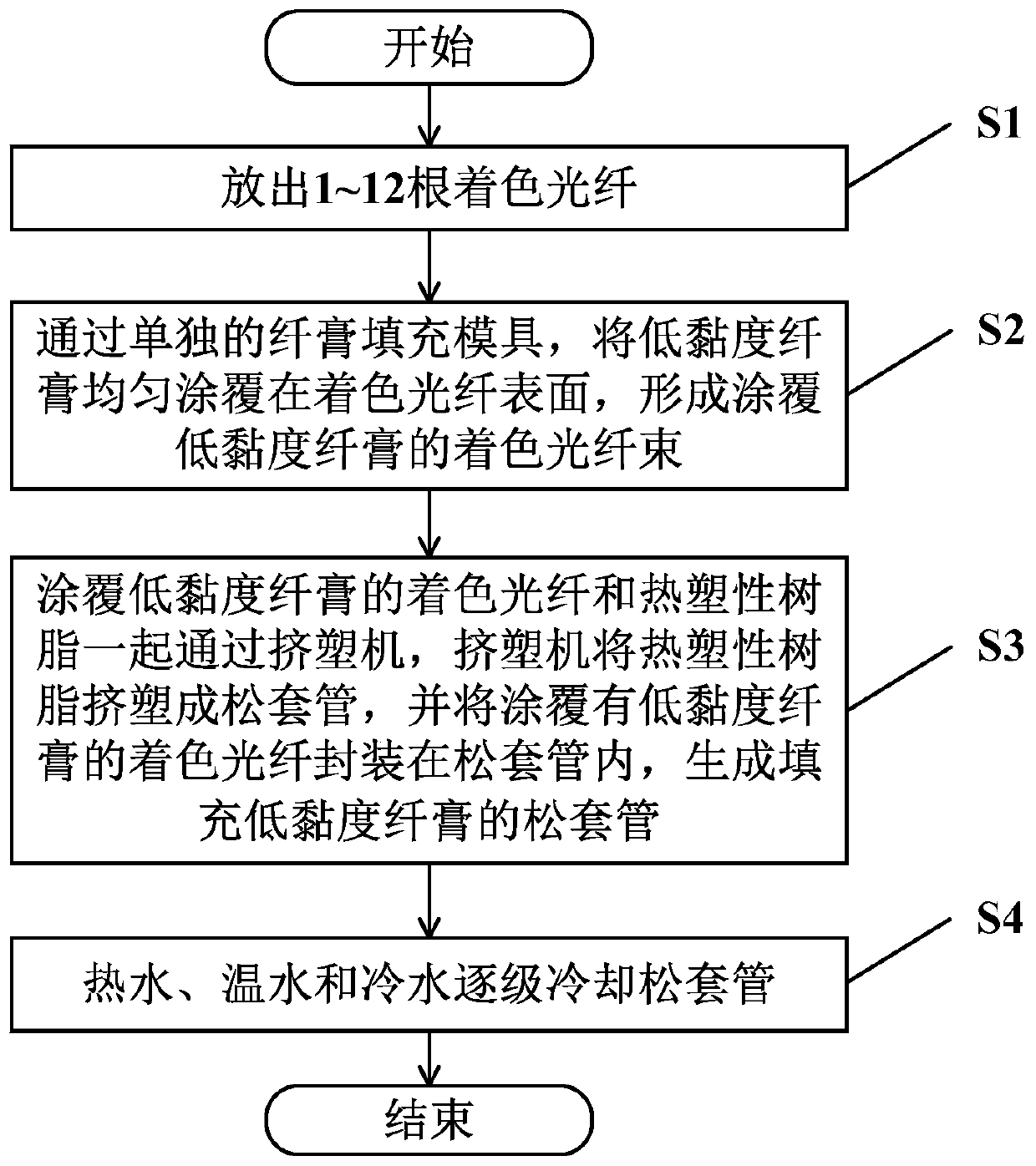

[0028] see figure 1 As shown, the embodiment of the present invention provides a loose tube low-viscosity fiber paste filling process, including the following steps:

[0029] S1. Release 1-12 colored optical fibers 1 .

[0030] Control the pay-off tension or pay-off speed of colored optical fiber through PLC (Programmable Logic Controller, programmable logic controller); the pay-off tension of colored optical fiber can be adjusted to 50-160g;

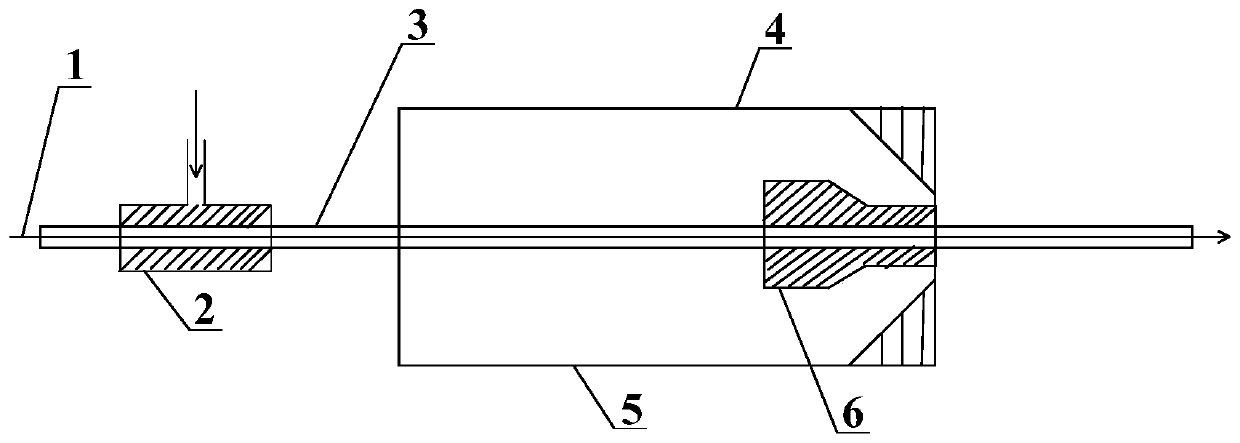

[0031] S2, see figure 2 As shown, the extruder includes a fiber paste filling mold 2, an extruder head 5, and an extruder die 6. Through a separate fiber paste filling mold 2, the low-viscosity fiber paste is evenly coated on the surface of the colored optical fiber 1, A colored optical fiber bundle 3 coated with a low-viscosity fiber paste is formed.

[0032] figure 2 For a schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com