Angle and distance testing device and method of ultrasonic probe

An ultrasonic probe and testing device technology, which is applied in radio wave measurement systems, instruments, etc., to achieve the effect of ensuring reading accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

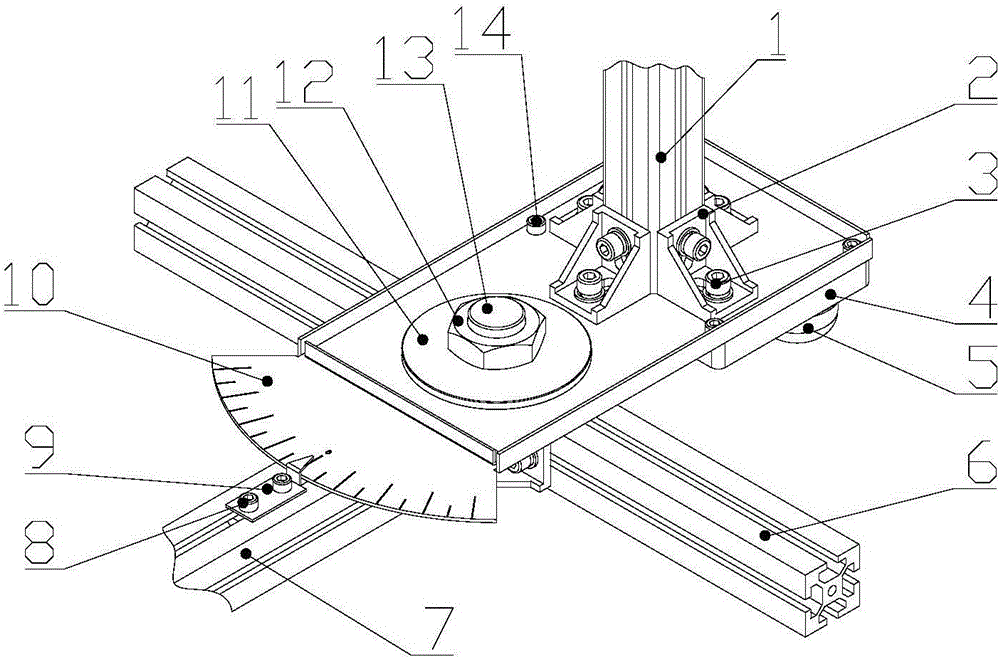

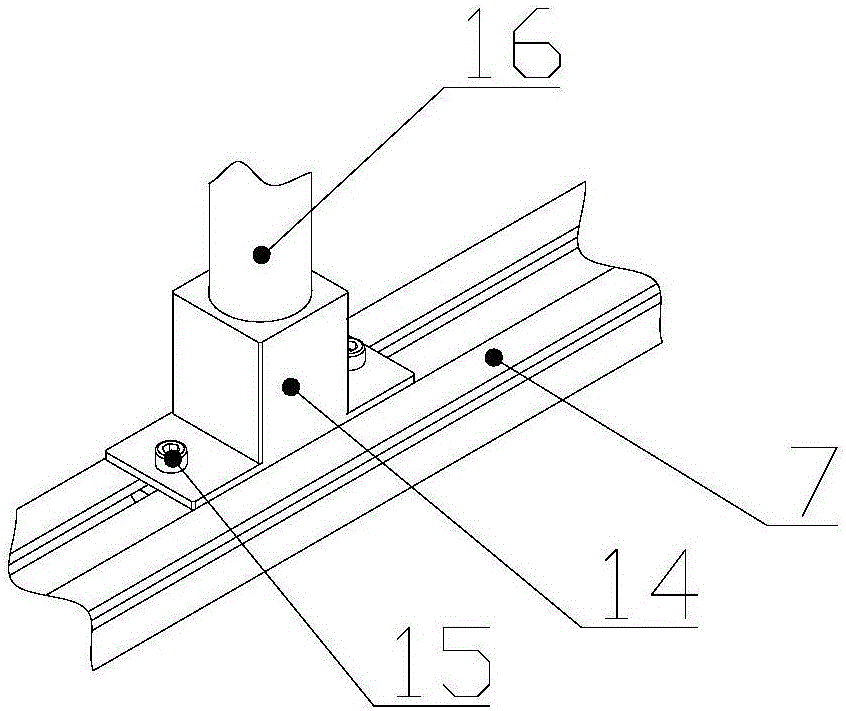

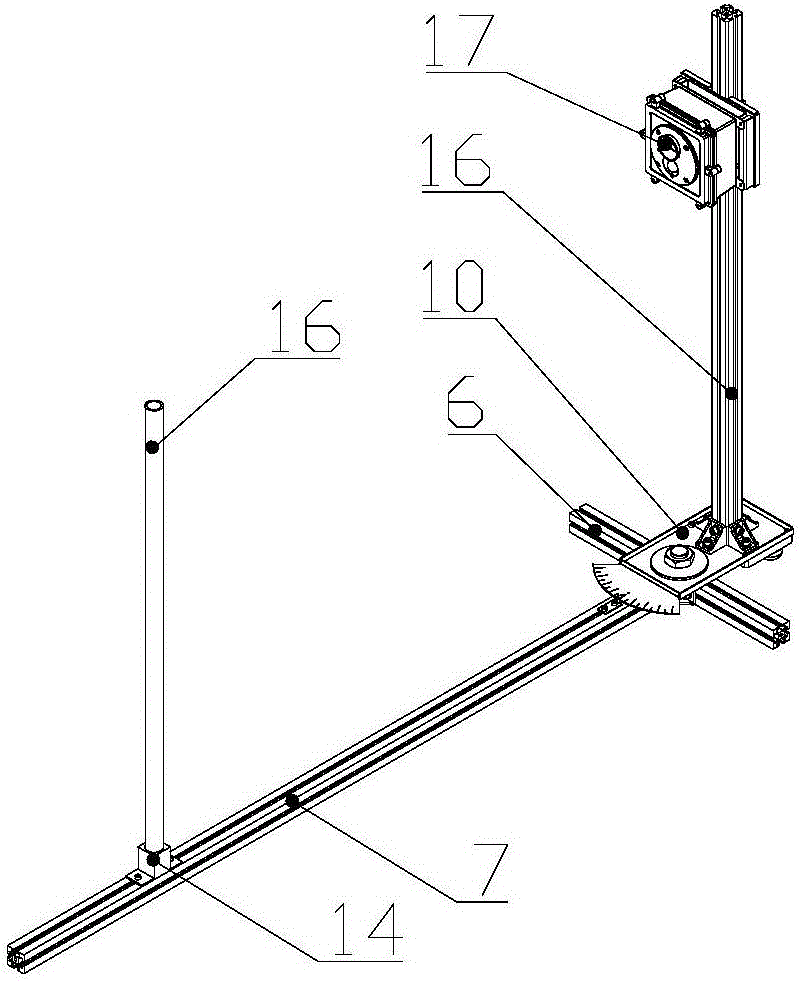

[0039] An angle and distance testing device for an ultrasonic probe, comprising: a longitudinal slide rail 7, a transverse support rail 6 and a vertical slide rail 1, an ultrasonic probe 17 is fixed on the side of the vertical slide rail 1, and the transverse support rail 6 and the longitudinal slide rail 7 are fixed In one body and the vertical slide rail 7 is arranged on the side of the horizontal support rail 6, one horizontal and one vertical form a T-shape to ensure the stability of the track. The vertical slide rail 1 and the chassis are fixed as an integral structure, and an angle plate 10 is set on one side of the chassis relative to the top of the longitudinal slide rail 7. The angle plate 10 and the chassis are integrally manufactured, and the angle plate 10 and the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com