Method for detecting content of carbon and sulfur in graphene based on high temperature combustion infrared absorption process

A technology of high-temperature combustion and infrared absorption, which is applied in the direction of measuring devices, preparation of test samples, chemical analysis by means of combustion, etc., can solve the problems of combustion splash, sample loss, and narrow heating space structure of high-frequency combustion reaction chamber, etc., to achieve The effect of increasing the weighing amount and satisfying the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

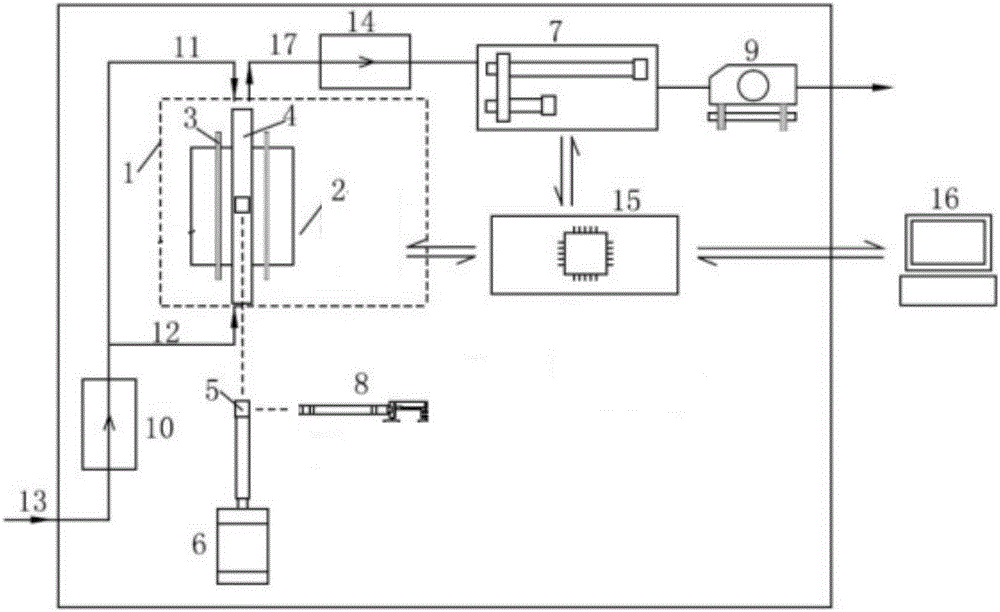

[0068] First, the preparation of the high temperature combustion infrared carbon sulfur analyzer

[0069] Turn on the power switch of the high-temperature combustion infrared carbon-sulfur analyzer. The infrared detection system 7 needs to be preheated for about 1 hour to reach a constant temperature and a stable baseline; 4. Start heating the surrounding silicon carbide rods 3, and wait for the temperature to stabilize; then turn on the power gas (ordinary nitrogen, 0.25MPa-0.35MPa), and turn on the carrier gas (oxygen, purity≧99.5%, 0.15-0.25MPa).

[0070] First analyze 2 to 3 waste samples, saturate the analysis gas path, and stabilize the instrument.

[0071] The second step is to prepare and weigh the sample

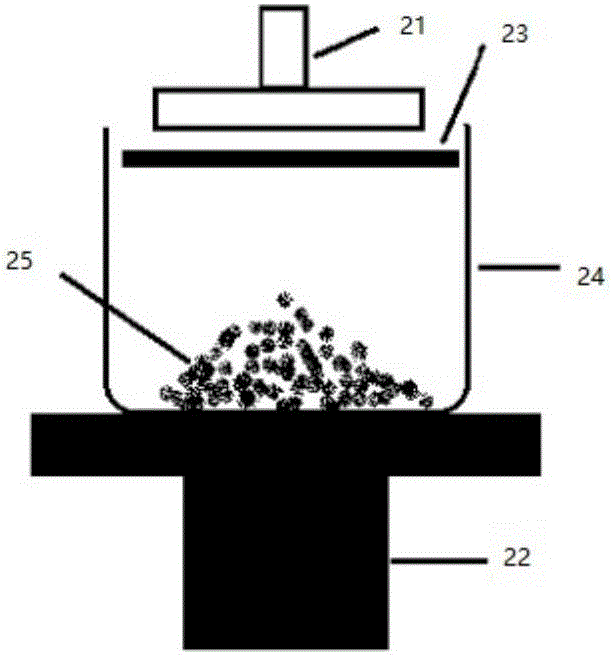

[0072] use figure 2 In the sample tableting device, place the prepared bag 24 between the pressure rod 21 and the bottom support 22, pour an appropriate amount of graphene samples into the bag 24, cover the bag upper cover 23, and apply pressure to start tabletin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com