Underground structure construction-oriented soil performance monitoring device and working method thereof

A technology of soil performance and monitoring devices, applied in the direction of measuring devices, instruments, etc., can solve the problems of not being able to measure multiple depths at measuring points, changes, and horizontal displacements that cannot be further measured, and achieve multi-directional automation testing and extensive engineering Application prospects, the effect of significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

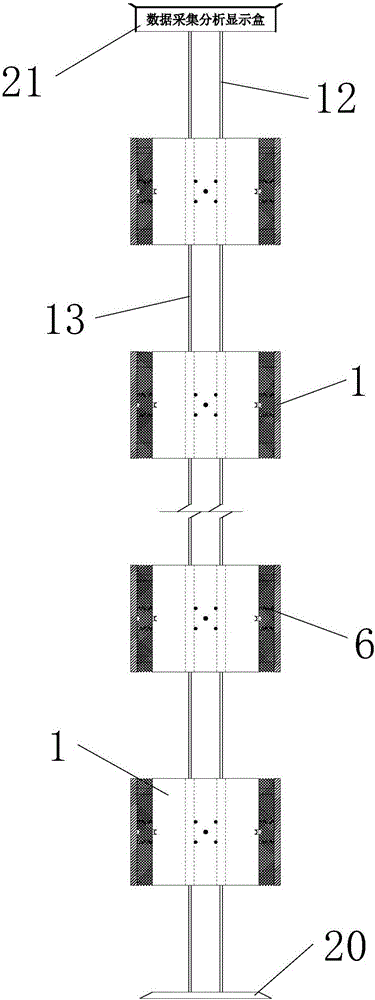

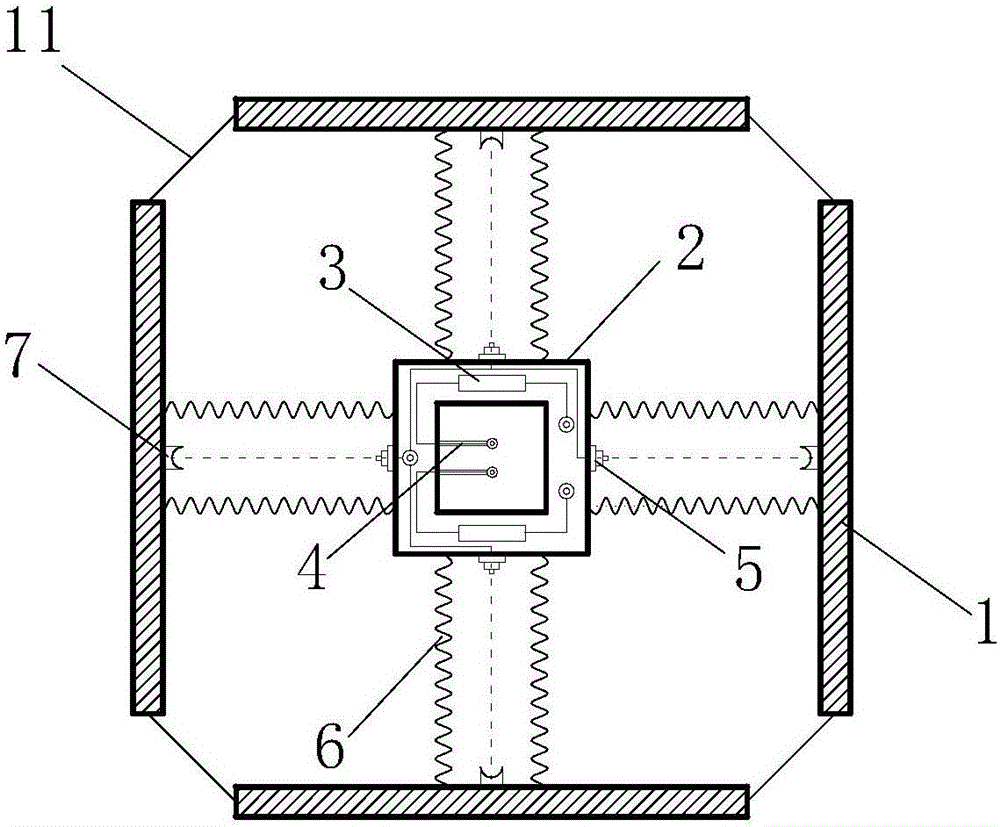

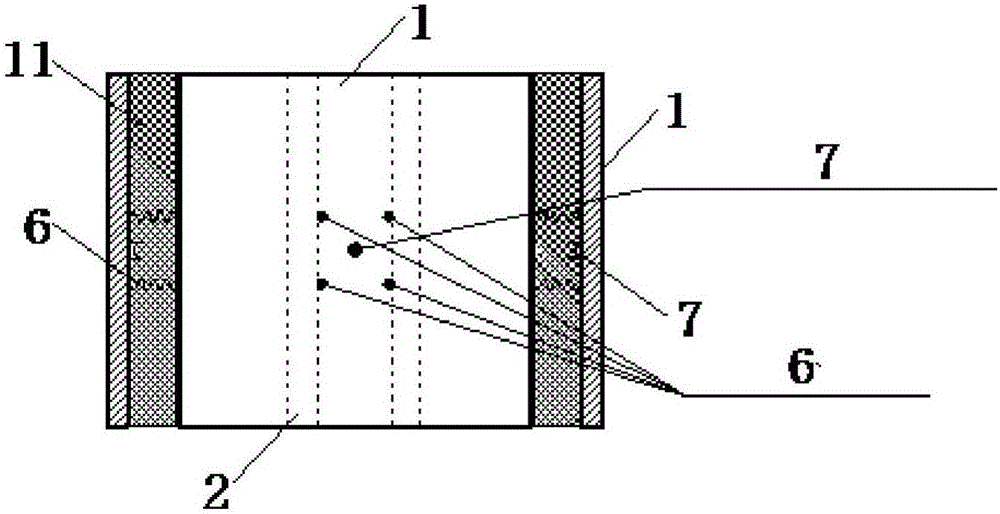

[0032] Embodiment: A soil performance monitoring device for underground structure construction, the buried depth is selected according to the engineering situation, and four monitoring sub-devices are set, such as figure 1 As shown, the four monitoring sub-assemblies are connected in sequence along the vertical direction, and the monitoring sub-device at the bottom is connected to the base 20 for support. Each monitoring sub-device such as figure 2 , 3 As shown, it includes a circuit protection box 2 and four earth pressure contact plates 1 surrounding the four sides of the circuit protection box 2, and the water-permeable non-woven fabric 11 is wrapped around the city surrounded by the four earth pressure contact plates 1 to only allow groundwater to penetrate. , the circuit protection box 2 is located in the middle part surrounded by the earth pressure contact plate 1 and the water-permeable non-woven fabric 11. The inner wall of each earth pressure contact plate 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com