Drying device

A technology of drying equipment and drying cylinder, which is applied in the direction of drying solid materials, drying gas arrangement, lighting and heating equipment, etc. It can solve the problems of affecting industrial production steps and slow drying speed of dryers, so as to prevent long-term retention around materials , the effect of slowing down the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

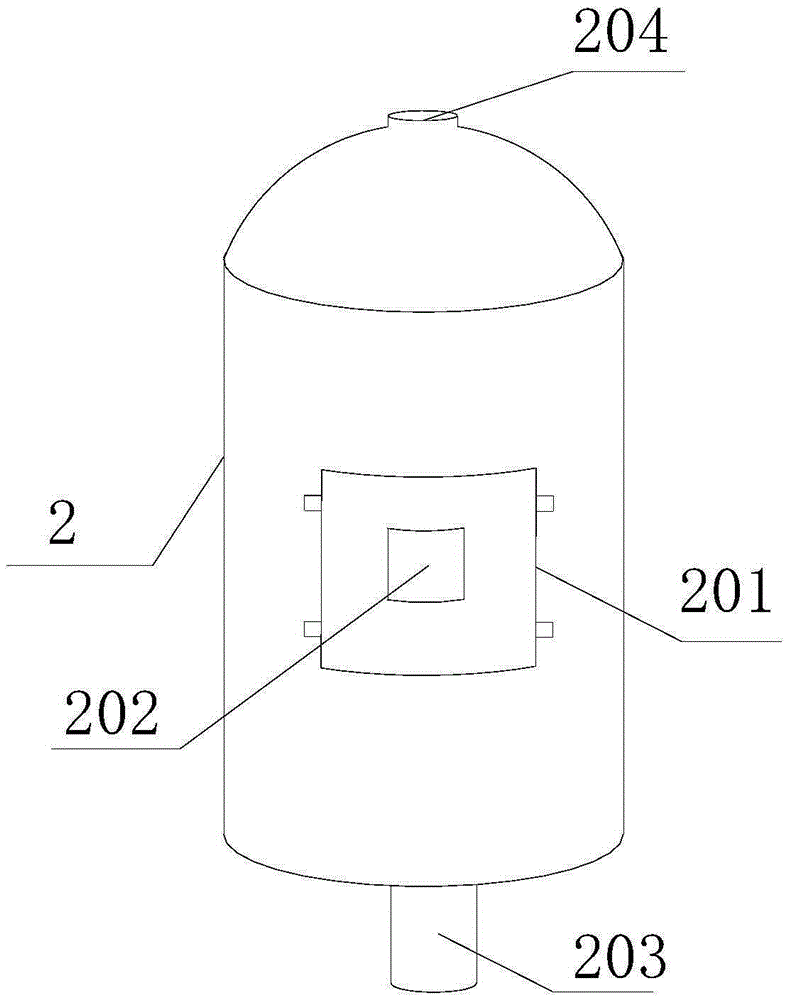

[0019] Such as Figure 1 to Figure 3 As shown, a drying device includes a frame 1 and a drying cylinder 2 fixed on the frame 1. The drying cylinder 2 is in the shape of a hollow cylinder, and a material door 201 is arranged on its side, and the inside is matched with the material door 201. The position is provided with a material rack, the frame 1 is provided with an air inlet device 3, the air inlet device 3 includes an air pump 301, a heater 302 and a dryer 303, and the air outlet of the air pump 301 is connected to the air outlet through the dryer 303 and the heater 302 The inlet 203 at the lower end of the drying cylinder 2 and the air inlet of the air pump 301 are connected to the outlet 204 at the top of the drying cylinder 2 .

[0020] It can be seen that in the present invention, wind heat is mainly used to heat the material, and the blower is to actively blow the hot air onto the material, and the heating speed is naturally faster. For example, in the prior art, a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com