Efficient combined type flash drum pump unit

A compound and flash evaporation technology, which is applied in the direction of refrigerators, mechanical equipment, refrigeration components, etc., can solve the problem of liquid refrigerant entering, and achieve the effect of increasing cooling capacity, improving work efficiency, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

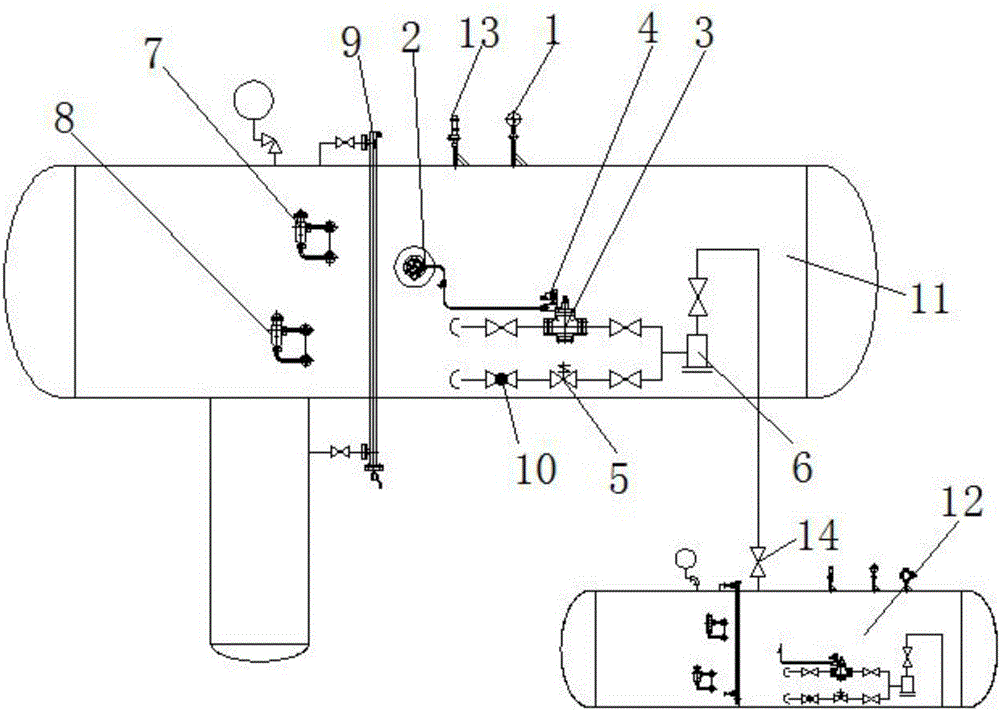

[0011] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

[0012] refer to figure 1 , a high-efficiency composite flash barrel pump unit, including a barrel body 11 of a flash barrel 12 and a low-pressure circulation barrel, and a safety valve 13 and a pressure gauge 1 are sequentially installed on the top of the barrel body 11, and the flash barrel 12 and the low-pressure circulation barrel are sequentially installed. The electrical equipment on the circulation bucket is also electrically connected with the external main control board.

[0013] A liquid supply pipe is connected to the flash tank 12 through an electric pilot valve 14, and a filter 6 is installed on the end of the liquid supply pipe far away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com