Touch smart burner

A burner, touch-type technology, applied in the burner, combustion type, combustion method and other directions, can solve the problems of fire power adjustment, unstable ignition needle, low work efficiency, etc., to achieve easy ignition, simple structure, Use safe and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

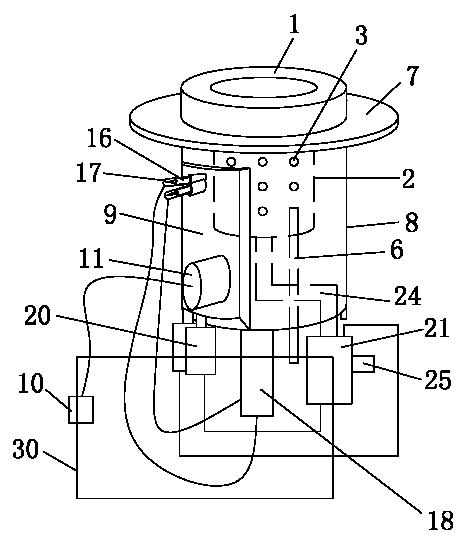

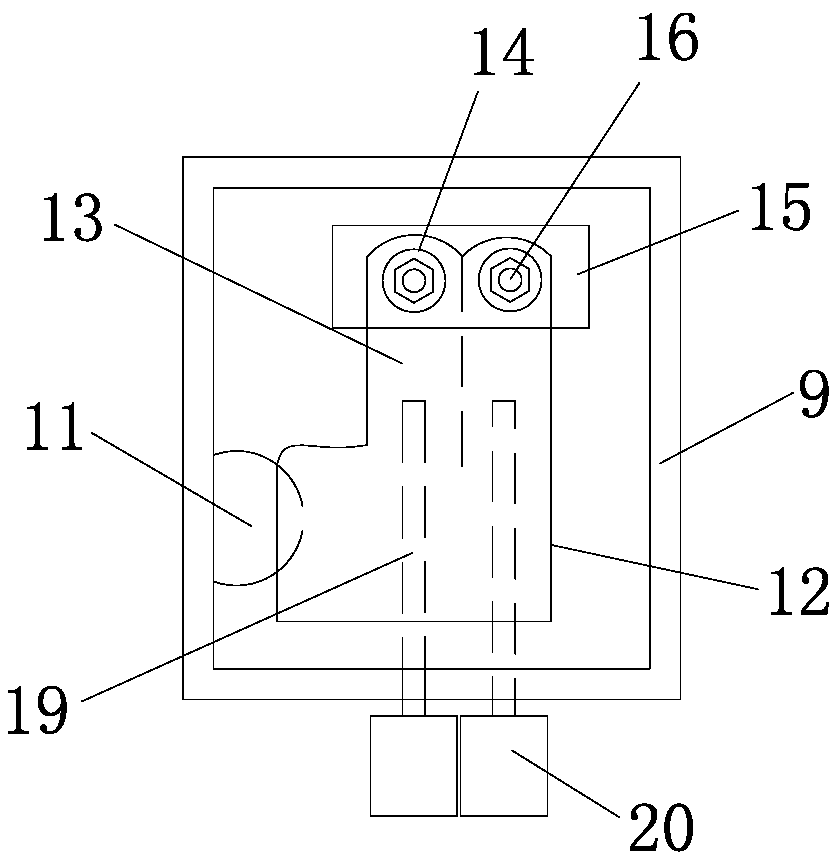

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

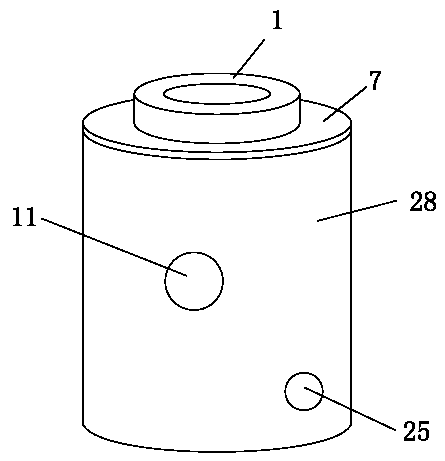

[0015] Depend on Figure 1-Figure 8 Given, the structure of the present invention is that the bottom of the flame nozzle 1 is communicated with a groove 2 with a closed bottom, and air holes 3 are evenly distributed on the peripheral wall of the groove, and the bottom of the groove has an upward vertically protruding air nozzle 4 , the upper wall of the jet head is evenly distributed with gas jet holes 5, the bottom of the jet head protrudes from the bottom of the groove and communicates with the gas outlet pipe 24, and the bottom of the groove has a downwardly extending groove on the outside of the jet head for flameout The probe thermocouple 6 for protection, the probe thermocouple is connected on the control circuit 30, the center of the flame nozzle has a through hole, and the flame nozzle is installed on the outer periphery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com