Eccentric mechanism capable of achieving continuous amplitude adjustment in motion

A technology of adjusting the amplitude and eccentric mechanism, which is applied in the direction of transmission, mechanical equipment, belt/chain/gear, etc. It can solve the problem of inability to continuously adjust the movement amplitude, and achieve the effects of low cost, low energy consumption and low failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

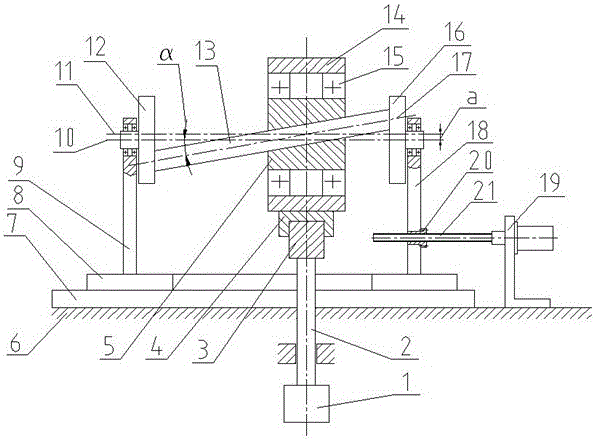

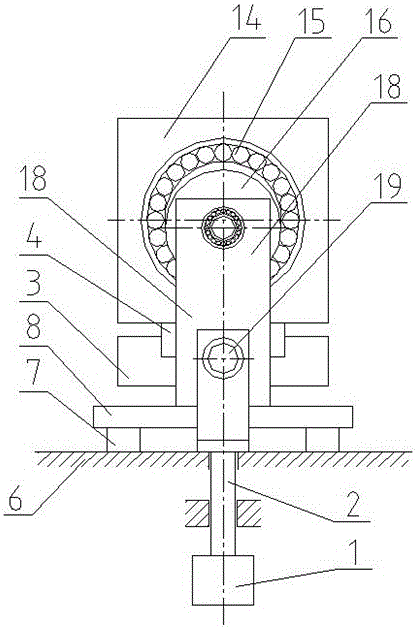

[0024] see figure 1 , figure 2 , an eccentric mechanism capable of continuously adjusting amplitude during motion, installed on a sine wave fatigue testing machine, used for four-point bending fatigue life test of asphalt mixture, including a driving shaft, an inclined shaft 13, a shaft sleeve 14 and an inclined sleeve 5; The driving shaft is disconnected from the middle to form a left half shaft 12 and a right half shaft 16, the left half shaft 12 and the right half shaft 16 have the same axis, and the oblique shaft 13 is connected between the left half shaft 12 and the right half shaft 16, The axis 17 of the oblique shaft intersects the axis 10 of the driving shaft, and the angle between the two is α; the oblique sleeve 5 is provided with an oblique through hole through which the oblique shaft 13 passes, and the oblique shaft 13 can pass through the oblique through hole. The oblique through hole in the sleeve 5 slides; the shaft sleeve 14 is rotatably connected to the obli...

Embodiment 2

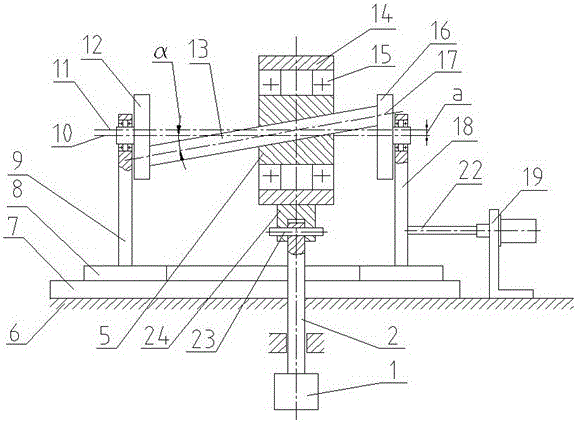

[0033] see image 3 , Figure 4 , an eccentric mechanism capable of continuously adjusting the range in motion, its shaft sleeve 14 and one end of the guide rod 2 are hinged through a pin shaft 23 and a connecting block 24, the connecting block 24 is fixedly connected to the shaft sleeve 14, and the end of the guide rod 2 The other end is connected with the actuator 1, and the guide rod 2 can move linearly along the plane perpendicular to the axis 10 of the driving shaft.

[0034] The driving mechanism 19 of the present embodiment is an air cylinder / oil cylinder, and the air cylinder / oil cylinder is connected on the frame 6 by a connecting frame, and the rod end of the piston rod 22 of the air cylinder / oil cylinder is connected on the right support 18; the piston rod 22 of the air cylinder / oil cylinder drives Left support 9, right support 18, slide plate 8 move together. The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com