Constant-force polishing device

A constant force, grinding seat technology, used in grinding drive devices, grinding/polishing safety devices, grinding/polishing equipment, etc., can solve the problems of increasing distance, easy damage to the manipulator, and the size deviation of the workpiece cannot be too large. , to achieve the effect of reducing the consistency of the workpiece, improving the grinding efficiency and reducing the grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described now in conjunction with accompanying drawing.

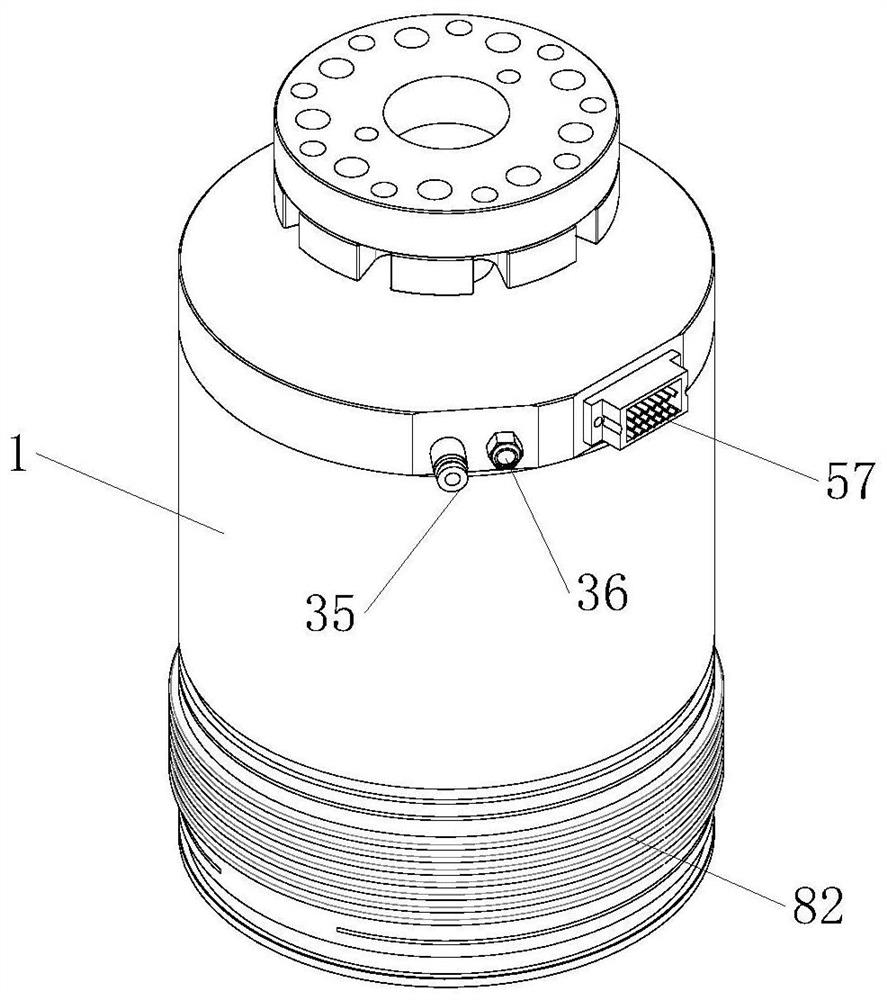

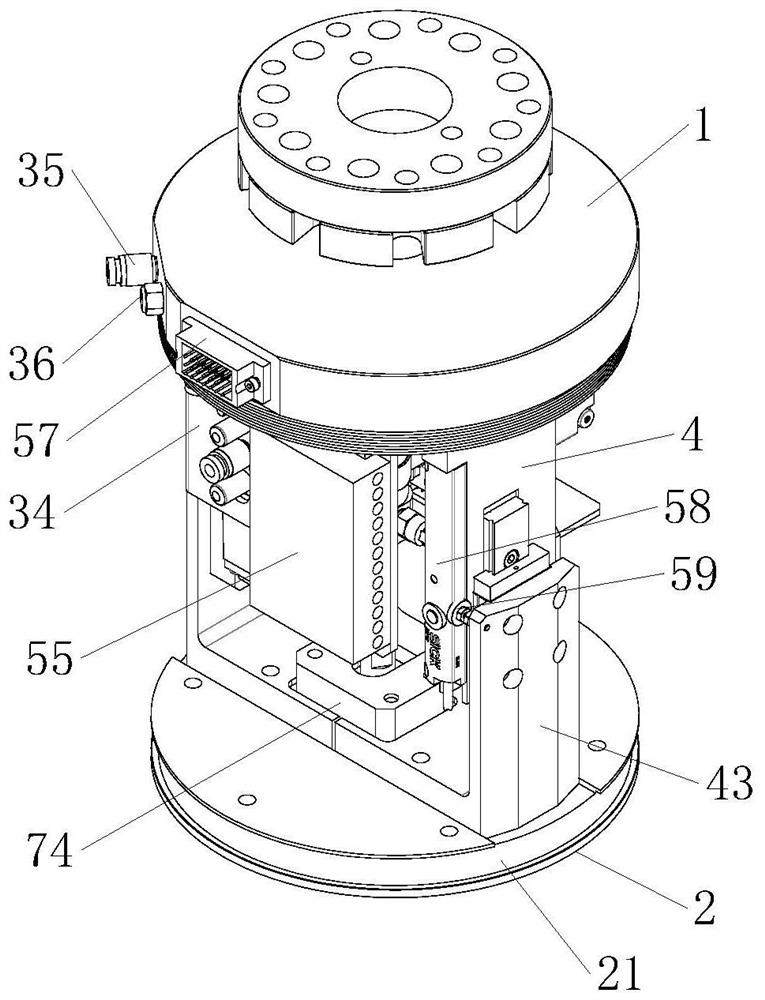

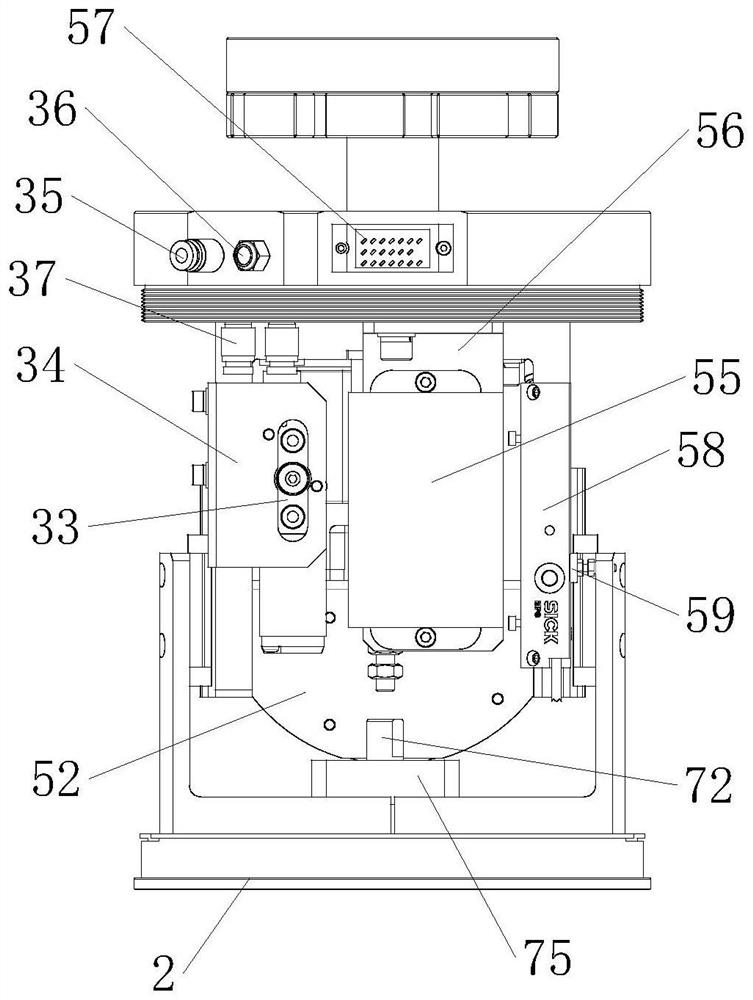

[0024] like Figure 1 to Figure 7 As shown, a constant force grinding device includes a proportional control valve 31, a cylinder 7, a connecting seat 1, a guide bracket 41, a lifting bracket 43, a grinding seat 2, a control panel 51, a protective tube 81 and a telescopic dust cover 82.

[0025] The top of the connection base 1 is equipped with a connection head 10 for connecting with the manipulator. A wiring hole 11 , an air inlet hole 12 and an air outlet hole 13 are provided on the outer surface of the connection base 1 , and the wiring hole 11 , the air inlet hole 12 and the air outlet hole 13 are all communicated with the bottom of the connection base 1 . The first connector 35 and the second connector 37 are respectively installed at two ends of the air inlet 12 . The second joint 37 is connected to the proportional control valve 31 through an air pipe. Multi-core j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com