A long-span multi-storey anti-seismic frame structure system and its construction method

An earthquake-resistant frame and large-span technology, which is applied in earthquake resistance, building components, building structures, etc., can solve the problems of weak earthquake resistance, inconvenient construction, and poor lateral stiffness, and achieve improved seismic performance, convenient construction, and structural durability. uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

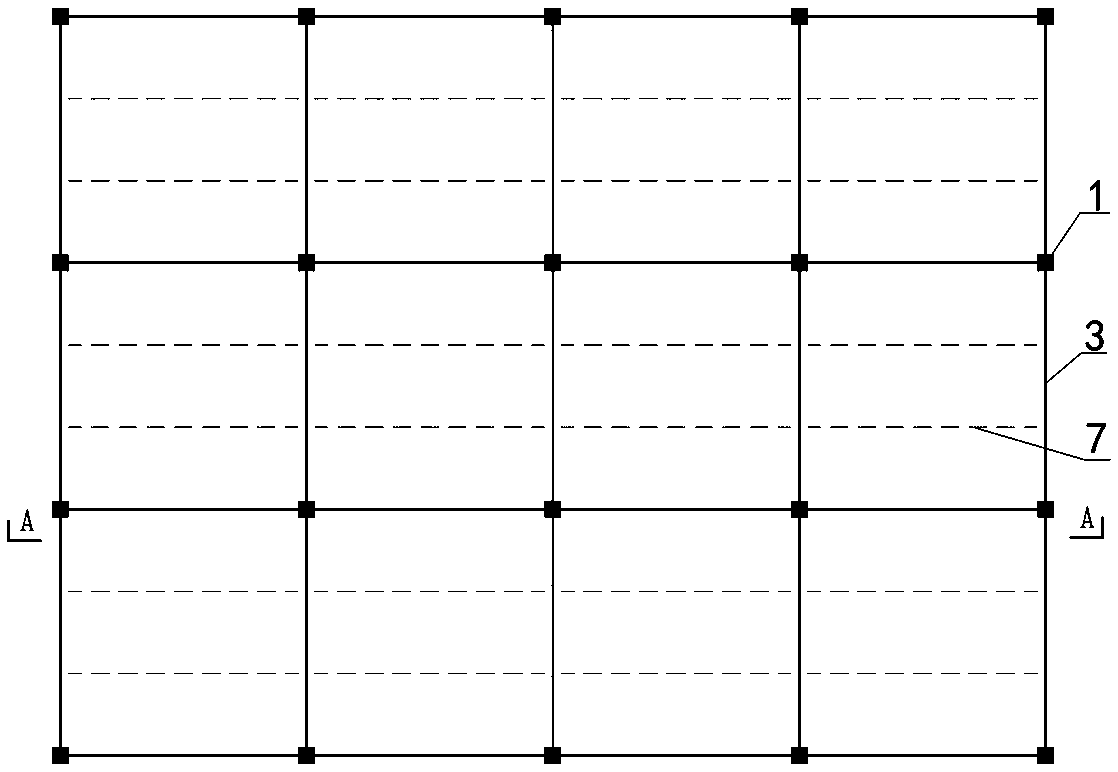

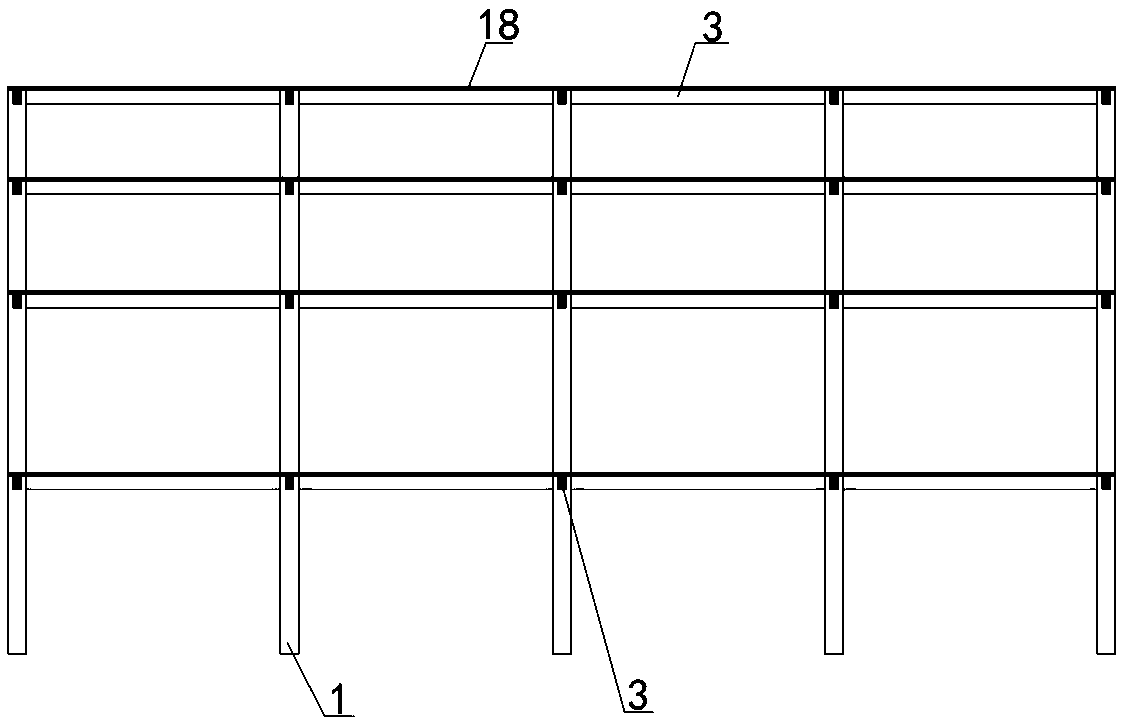

[0060] Embodiment one, see Figure 3-4 As shown, this long-span multi-storey anti-seismic frame structure system includes frame columns, frame beams, secondary beams 7 and floor slabs 18 of each floor, and a four-story frame structure with four horizontal spans and three vertical spans is taken as an example for illustration.

[0061] The frame columns include main frame columns 1 and auxiliary frame columns. There is at least one side auxiliary frame column 2 on each side of the outer grid. The auxiliary frame column can be arranged at full height in the multi-storey anti-seismic frame structure, or only arranged at the bottom of the building along the vertical height of not less than one floor, which is determined according to calculation.

[0062] In this embodiment, the number of side auxiliary frame columns 2 set between each main frame column 1 is 1-3 at the required positions around the building, so that the column spacing is reduced to 2-7m. The specific number depend...

Embodiment 2

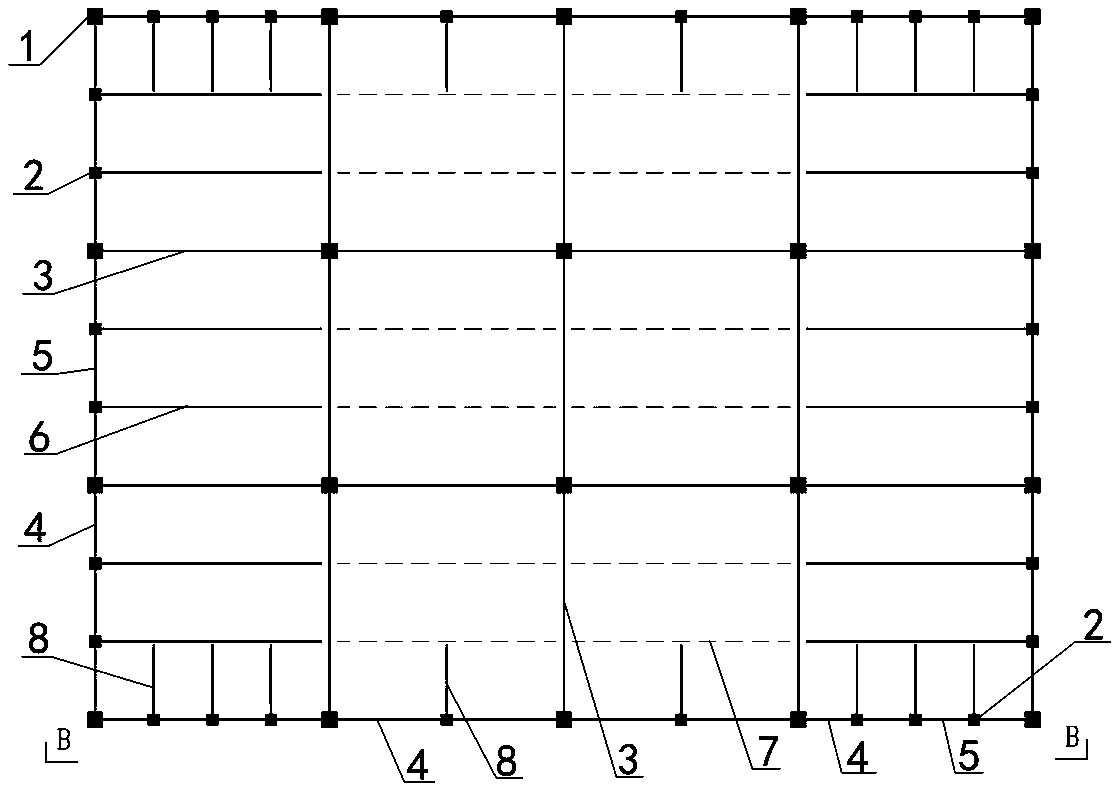

[0073] Embodiment two, see Figure 5-6 As shown, this long-span multi-storey anti-seismic frame structure system includes frame columns, frame beams, secondary beams 7 and floor slabs 18 of each floor, and a four-story frame structure with four horizontal spans and three vertical spans is taken as an example for illustration.

[0074] This embodiment Figure 6 Among the four horizontal spans, a side auxiliary frame column 2 is arranged between the main frame columns 1 of the three spans, all of which are four-storey high.

[0075] Among the three longitudinal spans, two of the two spans are arranged with two side auxiliary frame columns 2 between the main frame columns 1, all of which are four-storey high.

[0076] The difference from Embodiment 1 is that stairwells are set at two diagonal positions of the building, so the auxiliary frame columns also include staircase auxiliary frame columns 9 arranged around the building stairwells or elevators. The reason for this arrangem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com