Automatic dredging system for sump

A water tank and automatic technology, applied in construction, earth mover/excavator, etc., can solve the problems that the processing capacity of the filter press cannot meet the requirements, the cleaning of the paste sludge is not complete, and the drainage pipeline system is damaged, etc., to achieve The labor intensity of workers is low, the problem of clearing warehouse is eliminated, and the maintenance amount is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

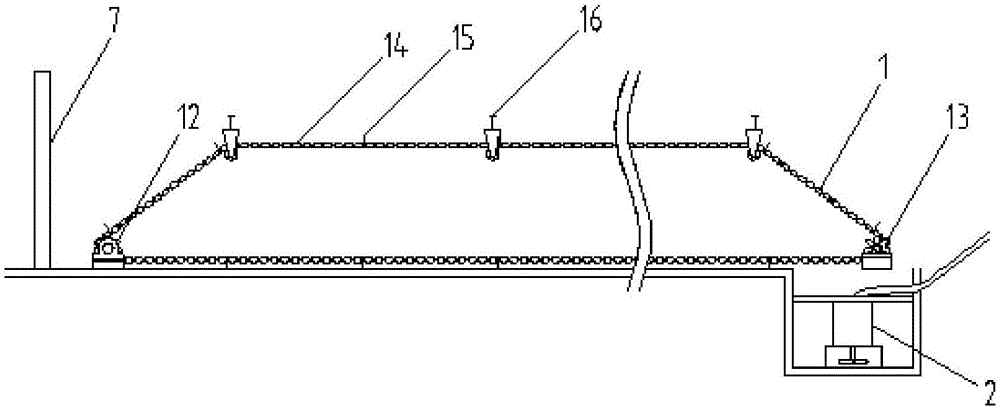

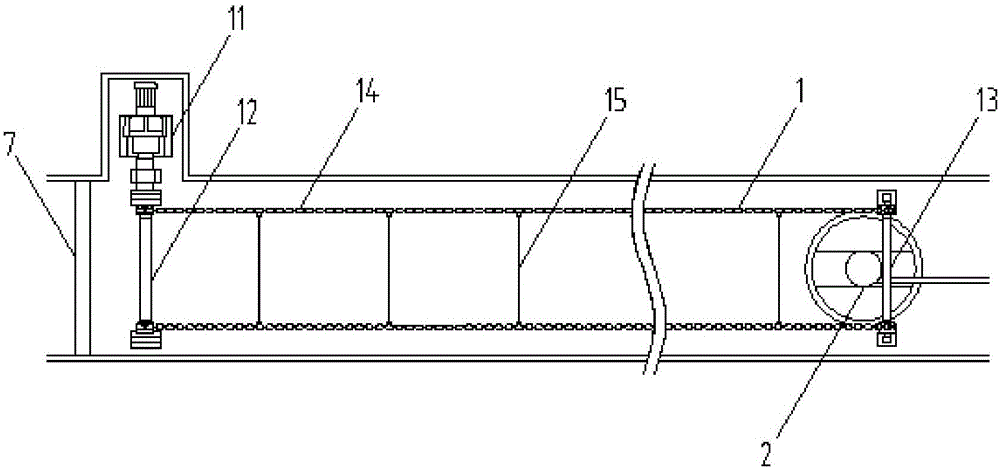

[0027] like Figure 1-3 As shown, the mine water tank includes two water tanks inside and outside. The automatic desilting system of the water tank of the present invention can be arranged in one or two of the water tanks. The automatic desilting system of the water tank in the embodiment is arranged in the inner water tank, including Mud scraper 1, submersible sewage pump 2, vibrating screen 3, filter press 4, water tank 5, mine car 6 and grating block 7.

[0028] The mud scraper 1 includes a drive mechanism 11 , a head shaft 12 , a tail shaft 13 , a chain 14 , a scraper 15 and a support wheel 16 .

[0029] Driving mechanism 11 adopts submersible motor, and submersible motor connects speed reducer by shaft coupling, drives head shaft 12 to rotate after speed reducer decelerates, and sprocket wheel is housed on the head shaft 12, drives chain 14 by sprocket wheel.

[0030] The chain 14 adopts a circular link chain, and there are two chains 14, and the two chains 14 are parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com