Reduction treatment method and reduction treatment furnace for metal ore

A processing method and technology for metal ore, applied in the field of metallurgy, can solve the problems of high reduction reaction temperature, complex equipment and high energy consumption, and achieve the effects of small equipment investment, small number of equipment and process cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1——the reduction treatment method of hematite:

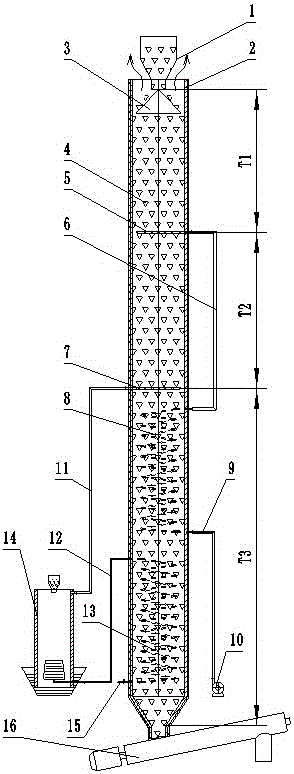

[0022] The equipment adopted in the present embodiment to the reduction of metal ore is as figure 1 As shown, there is a reduction treatment furnace for metal ores. There is a feed hopper 1 at the upper end of the reduction treatment furnace for metal ores. There is a flue gas outlet between the feed hopper 1 and the furnace shell 2 of the reduction treatment furnace for metal ores. The upper end inlet of the feed hopper 1 is the metal ore inlet of the metal ore to be reduced in the reduction treatment furnace of the metal ore. The lower end of the reduction treatment furnace of the metal ore is connected with a screw conveyor 16 through the collecting hopper part 8, and the metal ore of the screw conveyor 16 is The ore outlet is the metal ore outlet of the metal ore reduction treatment furnace, and the metal ore after the reduction reaction is exported out of the furnace from here.

[0023] The reduction trea...

Embodiment 10

[0036] Embodiment 10—the reduction treatment method of limonite:

[0037] The equipment adopted in the present embodiment to the reduction of metal ore is as Figure 5 As shown, there is a reduction treatment furnace for metal ores. There is a feed hopper 1 at the upper end of the reduction treatment furnace for metal ores. There is a flue gas outlet between the feed hopper 1 and the furnace shell 2 of the reduction treatment furnace for metal ores. The upper end inlet of the feed hopper 1 is the metal ore inlet of the metal ore to be reduced in the reduction treatment furnace of the metal ore. The lower end of the reduction treatment furnace of the metal ore is connected with a screw conveyor 16 through the collecting hopper part 8, and the metal ore of the screw conveyor 16 is The ore outlet is the metal ore outlet of the metal ore reduction treatment furnace, and the metal ore after the reduction reaction is exported out of the furnace from here.

[0038] The reduction tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com