Method for stabilizing pressure of gas collection pipe of coke oven

A gas collecting pipe pressure and coke oven technology, which is applied in the field of coking technology, can solve the problem that the pressure regulator on the gas collecting pipe cannot realize fine-tuning to stabilize the gas collecting pipe pressure, the automatic speed regulation lag of the hydraulic coupling of the blower, and the large fluctuation range of the suction of the blower, etc. Eliminate smoke and fire and furnace body leakage, improve the pressure of the gas collecting pipe, and reduce the effect of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

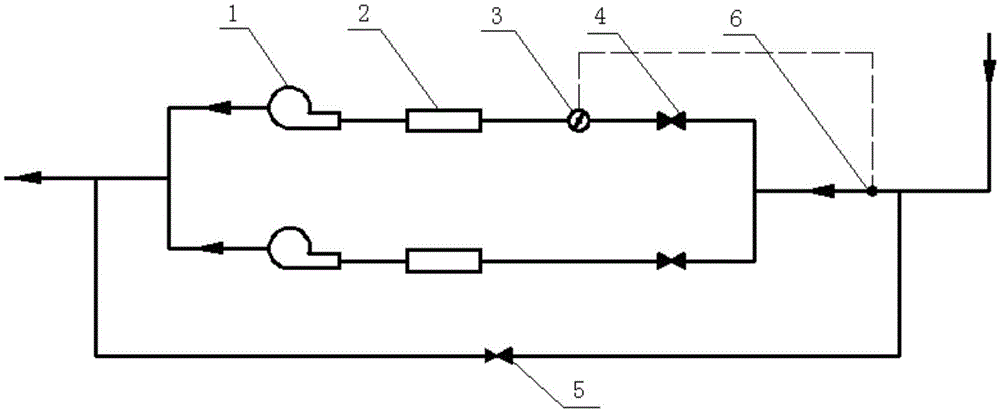

[0017] The present invention mainly adjusts the front suction of the blower 1 to keep approaching the set value by controlling the opening of the flap 3, so as to achieve the stability of the suction of the blower and the pressure of the air collecting pipe. The specific method is:

[0018] 1. Add a set of flap 3 automatic adjustment system on the gas pipeline in front of the gas blower 1 inlet, and at the same time, form an interlock between the flap 3 automatic adjustment system and the blower suction control point 6.

[0019] 2. The reasonable suction range of calibration blower 1 is 1500±200Pa.

[0020] 3. The reasonable working range of the adjustment of the front flap 3 of the calibration blower 1 is 30% to 70%.

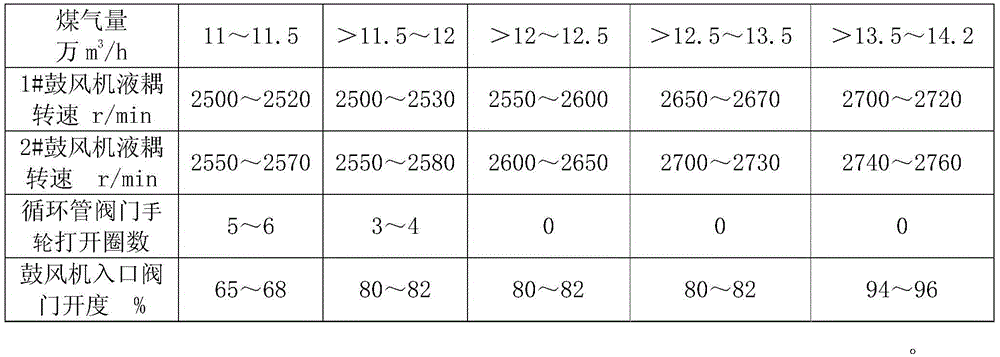

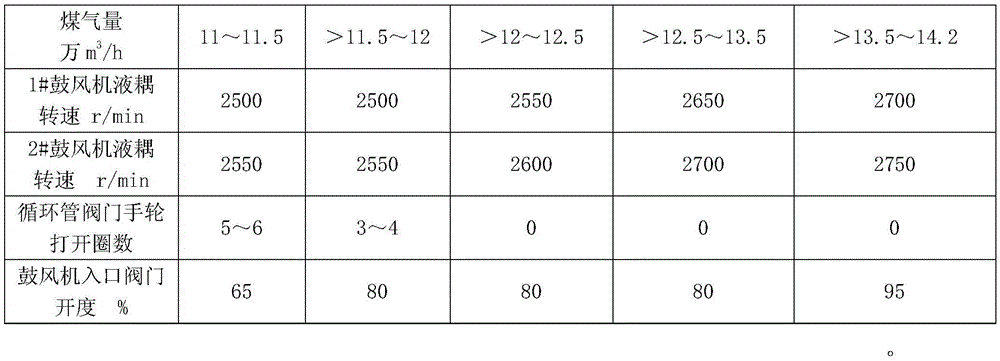

[0021] 4. Take the automatic adjustment of the front flap 3 of the blower as the main method, supplemented by adjusting the speed of the blower hydraulic coupler 2, the opening of the circulation pipe valve 5 and the blower inlet valve 4, and adjust the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com