Silence hot water pot

A hot water kettle and mute technology, which is applied to special materials, coatings, kitchen utensils, etc. of cooking utensils. Effect of Hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

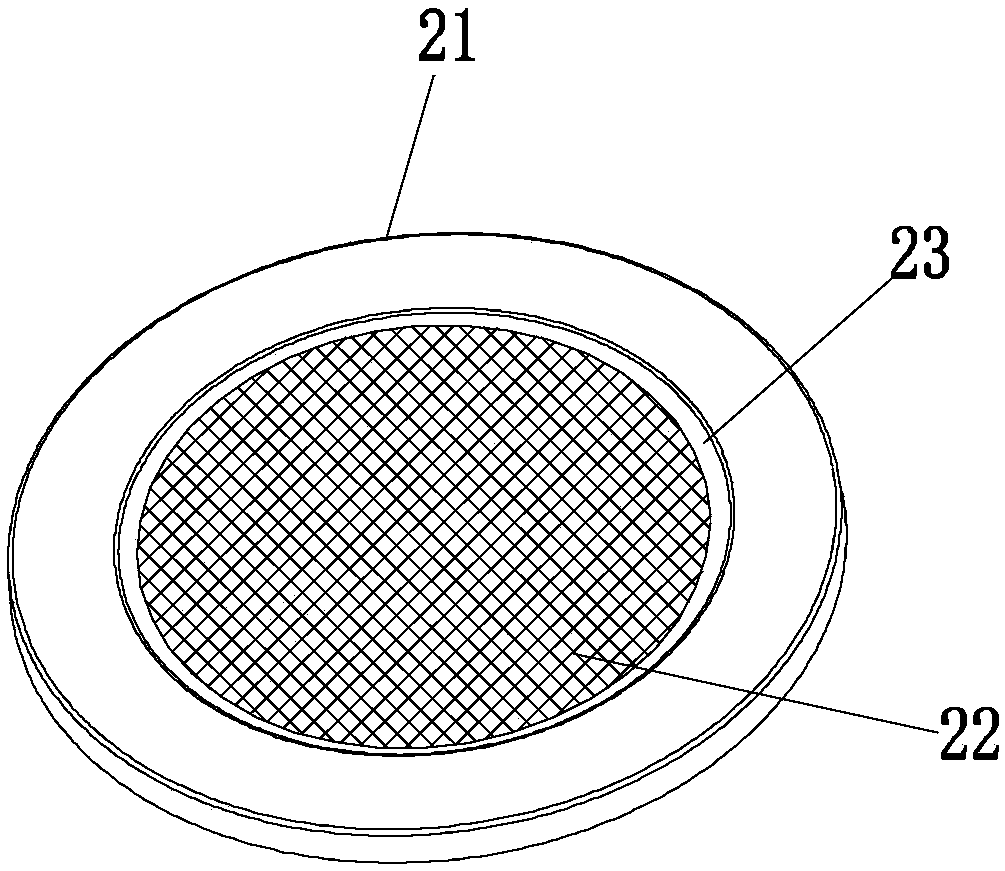

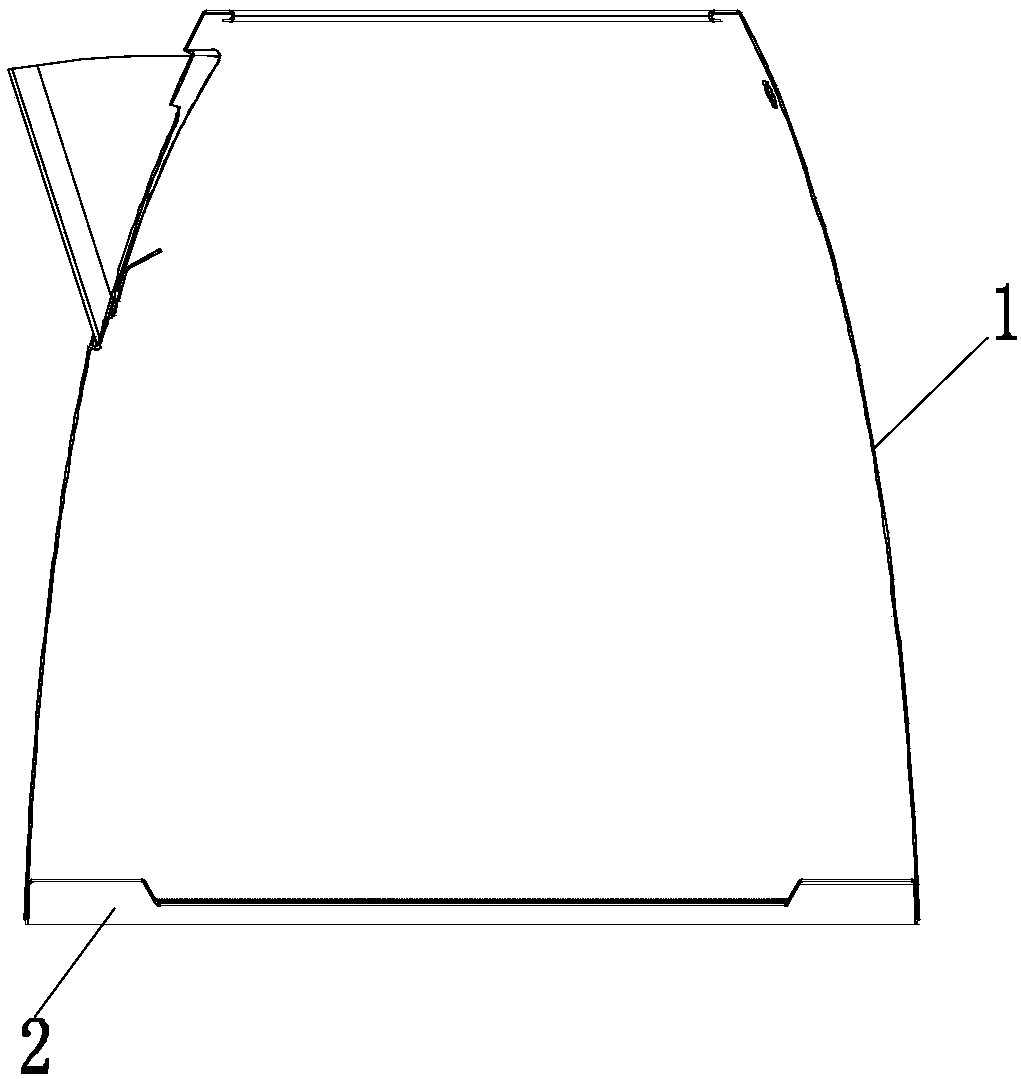

[0027] refer to Figure 1-2 , the present embodiment provides a silent hot water kettle, including a kettle body 1 and a heating disc assembly 2 arranged at the bottom of the kettle body, and an annular sealing ring is also provided at the connection between the heating disc assembly 2 and the kettle body 1;

[0028] The inner wall of the kettle body 1 is coated with a hydrophobic coating.

[0029] The heating disc assembly 2 includes a heating disc panel 21 and a heating tube, the heating tube is fixed on the lower surface of the heating disc panel 21; the upper surface of the heating tube panel 21 is coated with a layer of the hydrophobic coating layer. The heating plate assembly 2 also includes a temperature sensor disposed on the upper surface of the heating pipe panel 21, and the position corresponding to the temperature sensor on the upper surface of the heating pipe panel 21 is not coated with the hydrophobic coating. A concave portion 22 is provided in the middle of ...

Embodiment 2

[0037] The characteristics of this embodiment are: the hydrophobic coating is prepared from the following raw materials in parts by weight: 23 parts of N-methylpyrrolidone, 21 parts of toluene, 24 parts of titanium oxide, 16 parts of butanone, dimethyl 8 parts of amides, 6 parts of cyclohexanone, 1.5 parts of diacetone alcohol, and 0.5 parts of carbon black. Others are the same as in Example 1.

Embodiment 3

[0039] The characteristics of this embodiment are: the hydrophobic coating is prepared from the following raw materials in parts by weight: 23.5 parts of N-methylpyrrolidone, 22 parts of toluene, 18 parts of titanium oxide, 14 parts of butanone, dimethyl 6 parts of amide, 4 parts of cyclohexanone, 0.5 part of diacetone alcohol, and 0.1 part of carbon black. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com