Method for controlling oxygen solubility of original beer in cold-chain logistics process

A technology of cold chain logistics and beer, which is applied in packaging, liquid distribution, transportation and packaging, etc. It can solve the problems of restricting the production and sales of puree beer, and does not control the dissolved oxygen of puree beer. It achieves novel ideas and principles Reliable, broad-spectrum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

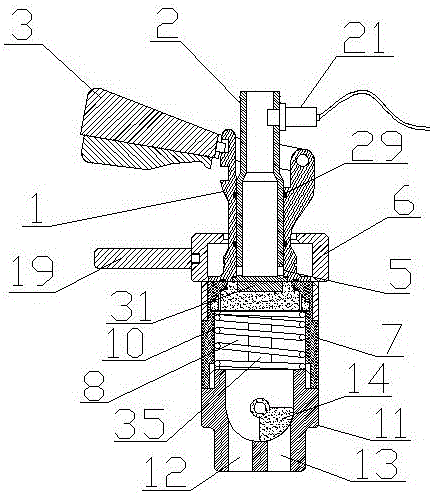

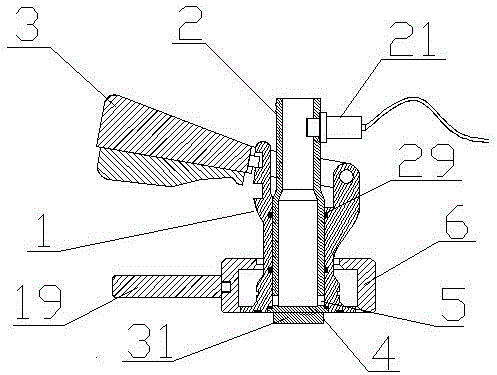

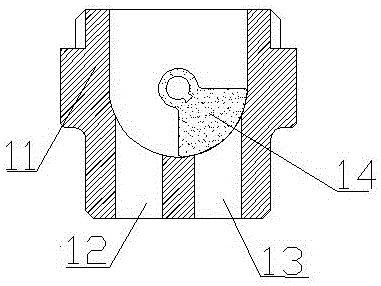

[0049] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

[0050] A method for controlling the dissolved oxygen of raw beer in the process of cold chain logistics, by controlling the delivery of raw beer from the factory to the fully enclosed wine injection where the raw beer is injected into the beer terminal; by setting a dissolved oxygen detection and feedback system, monitoring the original Oxygen content in pulp beer; by setting up a dissolved oxygen adjustment system, when the dissolved oxygen exceeds the standard, the dissolved oxygen is reduced by injecting carbon dioxide, and when the beer is detected to be deteriorated, the pipeline is cleaned by Unicom, and disinfectant is injected into the pipeline, thereby Guarantee the dissolved oxygen of raw beer in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com