Automatic disassembling method and device for anode carbon blocks

A technology of anode carbon block and carbon block, which is applied in the direction of transportation, packaging, and unstacking of objects. It can solve the problems of laboriousness and low efficiency of unpacking, and achieve the effects of simple structure, time-saving and labor-saving operation, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

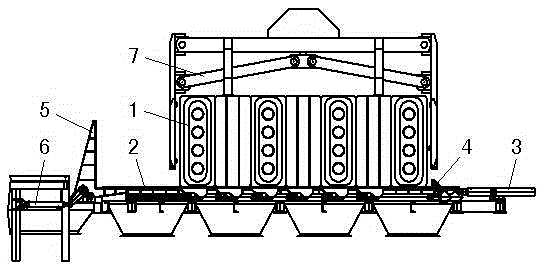

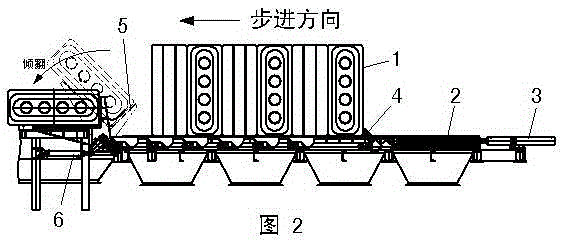

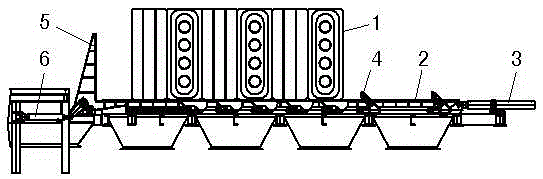

[0023] In this example, at runtime, such as figure 1 As shown, firstly, 7 dedicated cranes lift and transport a group of anode carbon blocks after firing, and every seven carbon blocks form a group. The group is hoisted onto the frame of the carbon block receiving device 2. At this time, the stepping block hydraulic cylinder 3 is in the retracted state. Heavy hammer type ratchet 4, except that the first head is in the push block state upwards, other ratchets are all in a horizontal state under the heavy pressure of the carbon block. The short arm of the L-shaped fork 5 is in the state of receiving the carbon block horizontally; the anode carbon block group is placed in place, and after the special crane 7 leaves, the step push block hydraulic cylinder 3 stretches out, and the first pawl (closest to the step Push block hydraulic cylinder is the first one), the carbon block group moves forward (such as figure 2 Move in the direction indicated by the middle arrow) until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com