Damp-proof moisture-retention cigarette package structure and production equipment thereof

A packaging structure and production equipment technology, applied in packaging, packaging cigarettes, transportation and packaging, etc., can solve the problems of no integration, large number of equipment, deformation of filter tip, etc., achieve fast forming speed, simple control system, avoid wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

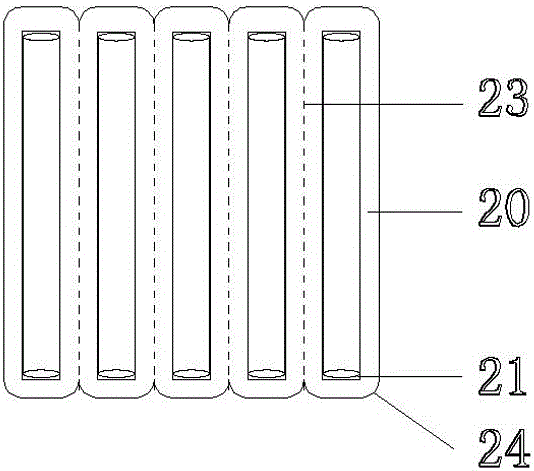

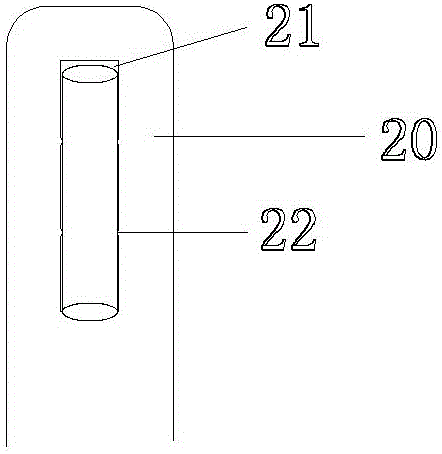

[0032] Such as figure 1 , 2 3. Shown in 3: A moisture-proof and moisturizing cigarette packaging structure, comprising a substrate sheet 20, a containing groove 21 and an encapsulation layer. The substrate sheet 20 is a PVC sheet, and the substrate sheet 20 is pressed with an opening in a cylindrical container. Slot 21, the size and shape of the containing slot 21 are the same as cigarettes and slightly larger than cigarettes. The open side of the base sheet 20 is sealed and packaged with the cigarettes in the containing slot 21 with a packaging layer. The length of the opening is equal to the length of the receiving groove 21.

[0033] The accommodating grooves 21 are evenly distributed on the substrate sheet 20, and there are tear marks 23 between adjacent accommodating grooves 21. The tear marks 23 penetrate the substrate sheet 20 longitudinally, and the ends of the tear marks 23 Round chamfer 24 is formed everywhere.

[0034] The base sheet 20 is provided with a breaking line ...

Embodiment 2

[0042] Such as figure 1 , 2 4. As shown in 4, a moisture-proof and moisturizing cigarette packaging structure includes a substrate sheet 20, a containing groove 21 and an encapsulation layer. The substrate sheet 20 is a PVDC sheet, and the substrate sheet 20 is pressed with an opening in a cylindrical housing Slot 21, the size and shape of the containing slot 21 are the same as cigarettes and slightly larger than cigarettes. The open side of the base sheet 20 is sealed and packaged with the cigarettes in the containing slot 21 with a packaging layer. The length of the opening is equal to the length of the receiving groove 21.

[0043] The accommodating grooves 21 are evenly distributed on the substrate sheet 20, and there are tear marks 23 between adjacent accommodating grooves 21. The tear marks 23 penetrate the substrate sheet 20 longitudinally, and the ends of the tear marks 23 Round chamfer 24 is formed everywhere.

[0044] The base sheet 20 is provided with a breaking line 25...

Embodiment 3

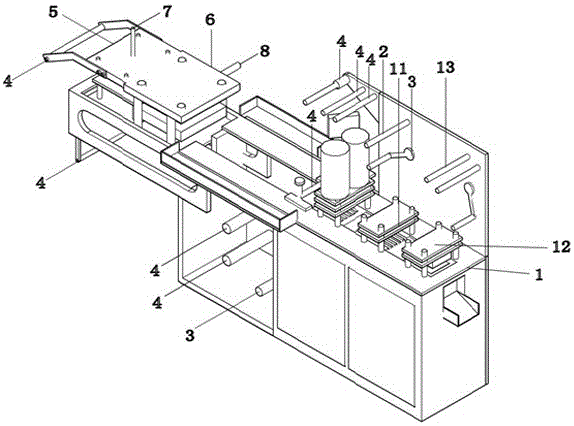

[0047] Such as figure 1 , 2 As shown in 4, the packaging structure of a moisture-proof and moisturizing cigarette described in this embodiment is the same as that of the first embodiment. A production equipment with a moisture-proof and moisture-preserving cigarette packaging structure. Its structure is basically the same as that described in Example 2. The difference is that: the bottom of the transfer tank 16 is provided with a suction hole, and when transferred from the arc-shaped feeder 14, the smoke is sucked in. The sticks are temporarily fixed in the containing groove, the cigarettes stop inhaling when they are transferred to the containing groove, and the cigarettes fall into the containing groove of the base material by gravity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com