Rear vehicle door with water guiding structure and vehicle

A water-guiding structure and rear door technology, which is applied in the sealing of doors, vehicle parts, and engines, can solve the problems of cost reduction and rear door lock body sticking, and achieve cost reduction, design cost reduction, and simplified processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

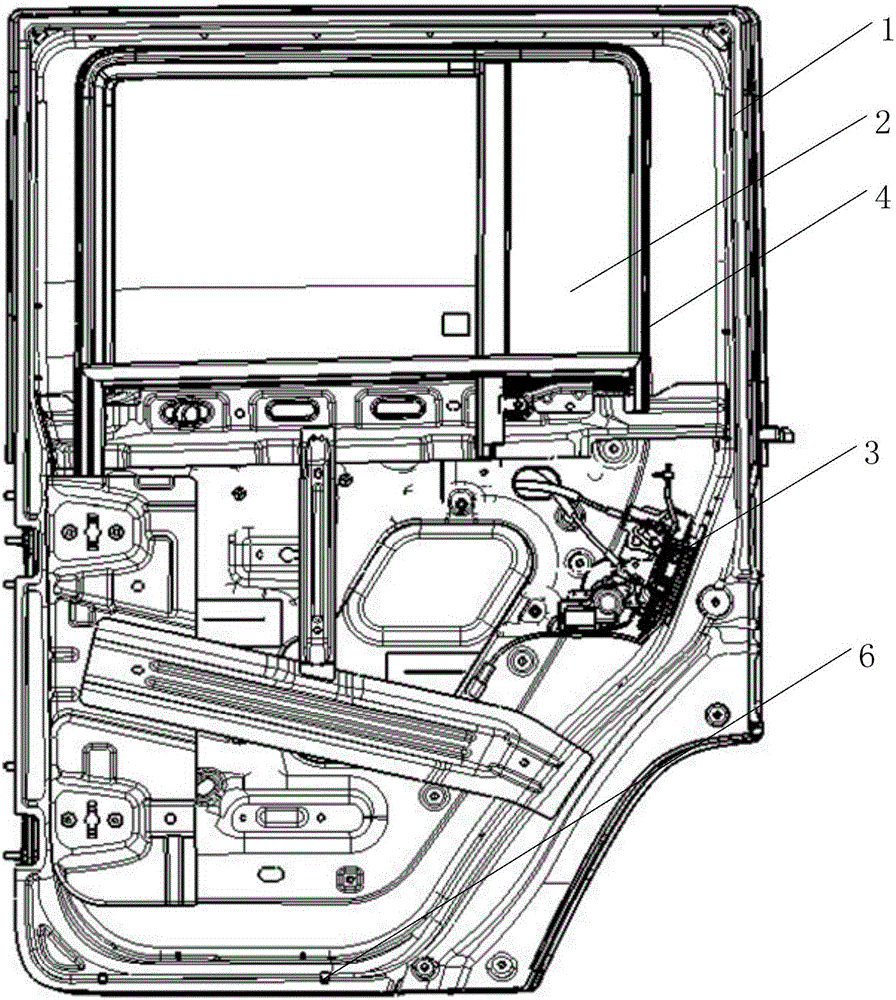

[0026] Example: such as Figure 1-5 As shown, a rear door with a water guide structure includes a rear door body 1, a rear quarter glass 2 arranged on the upper part of the rear door body 1 and a door lock 3 arranged in the middle part of the right side of the rear door body 1 , a sealing strip 4 is arranged between the rear quarter glass 2 and the rear door body 1, and the rear quarter glass 2 is flexibly connected to the sealing strip 4; it is close to the rear door body 1 A water guide groove 5 is arranged on the inner side, the water guide groove 5 is located below the lower end of the weather strip 4 and above the door lock 3 of the rear door body 1, and the water guide groove 5 is a shell with openings on the upper part and the left end body, the bottom of the rear door body 1 is provided with a drain hole 6 for draining the water derived from the water guide groove 5 .

[0027] The transverse width on the left side of the water guiding groove 5 is smaller than that on ...

Embodiment 2

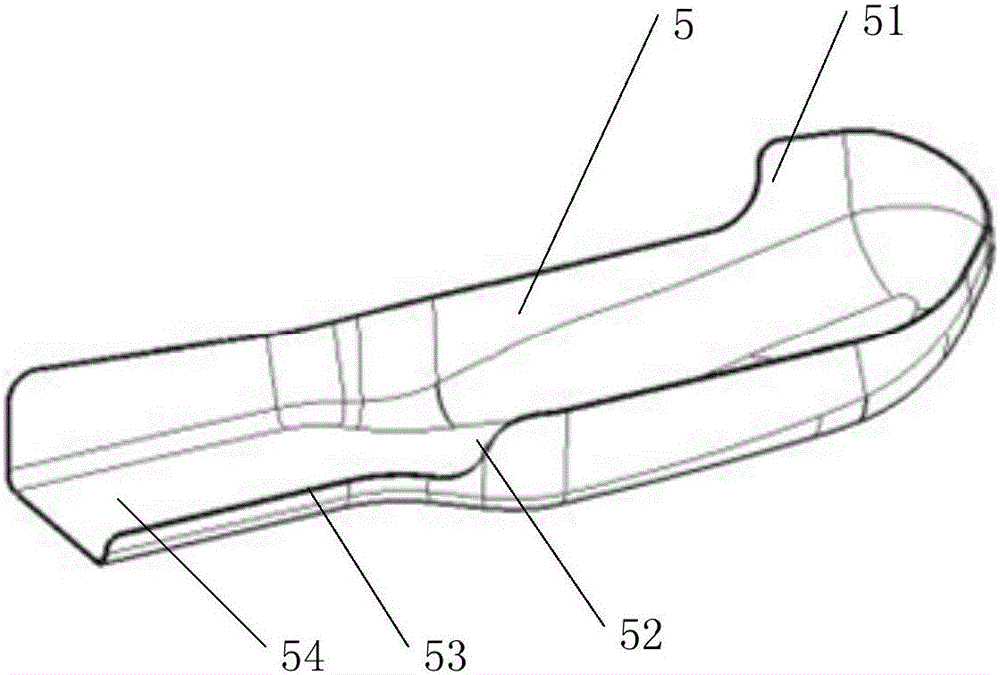

[0033] The difference from Embodiment 1 is that: the bottom of the water guiding groove 5 is provided with a slow flow groove 52 for buffering the water flow.

[0034] The bottom surface of the slow flow groove 52 is an outwardly convex curved surface.

[0035] A slot 53 is provided on one side of the left side of the water guiding groove 5 .

[0036] The side surface of the right end of the water guiding groove 5 is arc-shaped.

[0037] The bottom of the water guiding groove used in this embodiment is provided with a slow-flow groove, and the slow-flow groove used is a curved surface that matches the fluid, which is not only convenient for stamping processing, but also can reduce the splashing of water droplets caused by the impact of water flow, reducing The erosion effect of the water flow on the surrounding side; the establishment of the slow flow groove can avoid the existence of it, can store a small amount of rainwater in it, and avoid the phenomenon that a small amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com