Tetramethylammonium dizinc-vanadium oxygen-cluster catalyst as well as preparation method and application thereof

A technology of tetramethylammonium and tetramethylammonium hydroxide is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. There are problems such as halogen, and the effect of simple preparation method is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

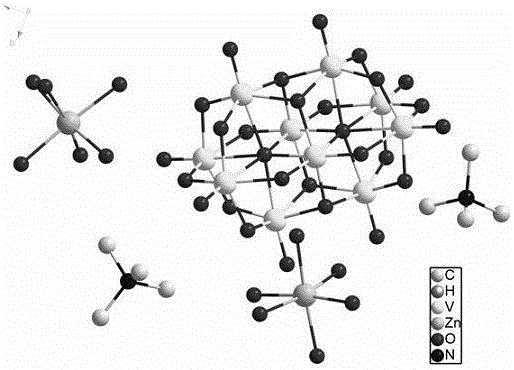

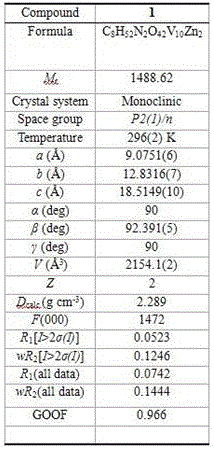

[0034] Specific example 1: compound [Zn(H 2 O) 6 ] 2 [(CH 3 ) 4 N] 2 V 10 o 28 2H 2 Preparation of O

[0035] In a clean beaker, add vanadium pentoxide (10mmol), tetramethylammonium hydroxide (10mmol), Zn(OAc) 2 (4mmol) and 15mL water, stirred vigorously for 12h, then raised the temperature to 40°C, reacted for 60min, cooled to room temperature after the reaction, filtered, stood still, the filtrate volatilized slowly, and a red substance was obtained after 4-5 days. The yield is about 63%.

specific example 2

[0036] Specific example 2: compound [Zn(H 2 O) 6 ] 2 [(CH 3 ) 4 N] 2 V 10 o 28 2H 2 Preparation of O

[0037] In a clean beaker, add vanadium pentoxide (15mmol), tetramethylammonium hydroxide (20mmol), Zn(OAc) 2 (6mmol) and 20mL water, stirred vigorously for 16h, then raised the temperature to 70°C, reacted for 100min, cooled to room temperature after the reaction, filtered, stood still, the filtrate slowly evaporated, and a red substance was obtained after 4-5 days. The yield is about 67%.

specific example 3

[0038] Specific example 3: compound [Zn(H 2 O) 6 ]2 [(CH 3 ) 4 N] 2 V 10 o 28 2H 2 Preparation of O

[0039] In a clean beaker, add vanadium pentoxide (12mmol), tetramethylammonium hydroxide (16mmol), Zn(OAc) 2 (5mmol) and 10mL of water, stirred vigorously for 12h, then heated up to 40°C, reacted for 60minmin, cooled to room temperature after the reaction, filtered, stood still, the filtrate slowly evaporated, and a red substance was obtained after 4-5 days. The yield is about 58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com