Nonmetal modified catalyst and preparation method for same

A kind of non-metal and catalyst technology, applied in the field of non-metal modified catalyst and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of described metal-free modified catalyst, comprises the following steps:

[0035] The ZSM-5 molecular sieve is sequentially subjected to the first roasting, ion exchange and second roasting to obtain the zeolite molecular sieve;

[0036] impregnating the zeolite molecular sieve in a non-metal source solution to obtain an impregnated product, the non-metal source being a phosphorus source, a boron source or a silicon source;

[0037] The impregnated product is subjected to a third calcination to obtain a non-metallic modified catalyst.

[0038] In the invention, the ZSM-5 molecular sieve is sequentially subjected to first roasting, ion exchange and second roasting to obtain the zeolite molecular sieve. In the present invention, the temperature of the first calcination is preferably 400-560°C, more preferably 450-520°C, most preferably 480-500°C; the time of the first calcination is preferably 6-12 hours, more preferab...

Embodiment 1

[0052] The ZSM-5 molecular sieve was calcined at 550°C for 6 hours, the ammonium nitrate solution was ion-exchanged at 60°C, and calcined again at 550°C for 4 hours to obtain the H-type ZSM-5 molecular sieve catalyst.

[0053] 0.11 g of diammonium hydrogen phosphate was supported on 2.5 g of H-type ZSM-5 molecular sieve catalyst by equal volume impregnation method, impregnated for 24 hours, dried and calcined at 480° C. for 4 hours.

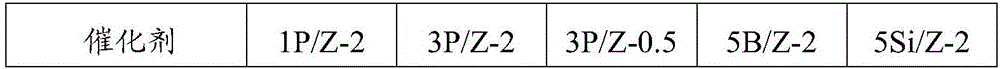

[0054] The prepared catalyst with 1 wt.% phosphorus supported on 2 μm ZSM-5 molecular sieve is marked as 1P / Z-2.

Embodiment 2

[0056] The ZSM-5 molecular sieve was calcined at 4500°C for 6 hours, the ammonium nitrate solution was ion-exchanged at 80°C, and calcined again at 500°C for 4 hours to obtain the H-type ZSM-5 molecular sieve catalyst.

[0057] 0.32 g of diammonium hydrogen phosphate was loaded on 2.5 g of H-type ZSM-5 molecular sieve catalyst by equal volume impregnation method, impregnated for 24 hours, dried and calcined at 530° C. for 4 hours.

[0058] The prepared catalyst with 3wt.% phosphorus supported on 2μm ZSM-5 molecular sieve is marked as 3P / Z-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com