Porous carbon flower adsorbing material and preparation method and application thereof

A technology of adsorption materials and porous carbon, which is applied in the field of adsorption materials, can solve the problems of complex preparation process and low adsorption capacity of solid adsorption materials, and achieve good recycling performance, high adsorption performance and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

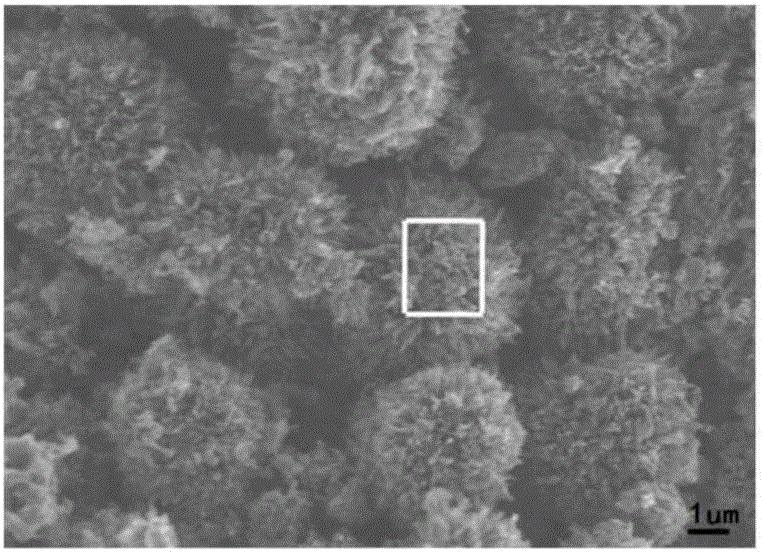

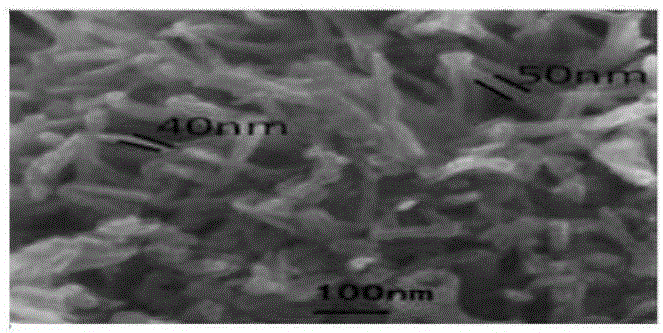

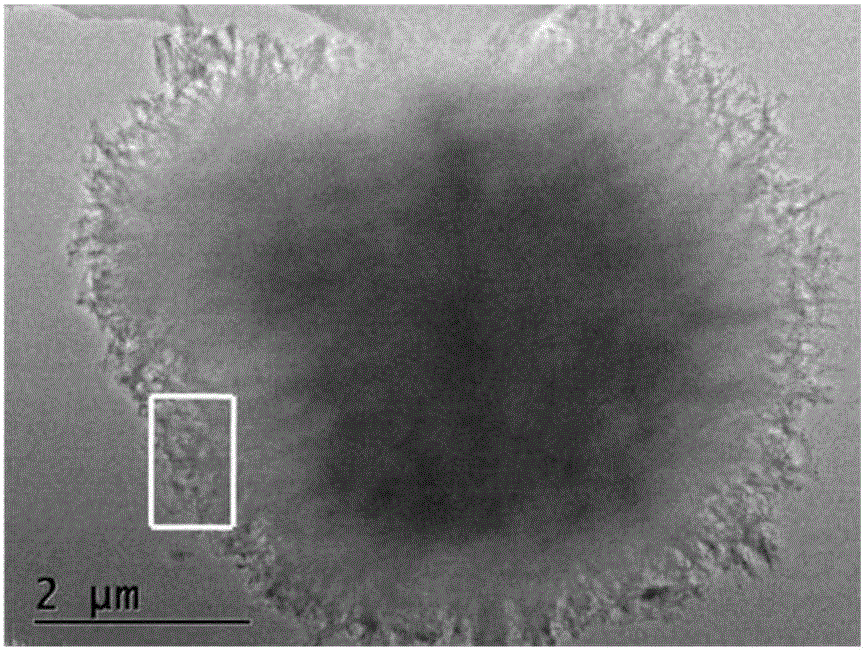

[0031] Porous carbon flowers are prepared by template-free method (solvothermal method):

[0032] Synthesize polyimide first: Measure 60mL of methylformamide into a beaker with a graduated cylinder, then add 0.89g of benzidine, put in a magnet and stir at a high speed until the benzidine is completely dissolved. Weigh 1.421 g of biphenyltetracarboxylic dianhydride and add it into the above beaker to continue stirring for 10 h to obtain polyimide.

[0033] Crystallization process: transfer the polyimide in the beaker to a reaction kettle with a polytetrafluoroethylene liner for crystallization at 180°C for 10 hours, filter the yellow precipitate obtained after crystallization in a vacuum filter, and use methyl formazan The amide was washed twice and then washed once with absolute ethanol, and then placed in a vacuum oven at 60° C. overnight to obtain a yellow solid powder.

[0034] High-temperature activation: the dried three-dimensional layered polymer obtained in the previou...

Embodiment 2

[0046] Porous carbon flowers are prepared by template-free method (solvothermal method):

[0047] Synthesize polyimide first: Measure methyl formamide in a beaker with a graduated cylinder, then add 0.89g of benzidine, put in a magnet and increase the speed to stir until the benzidine is completely dissolved, and the concentration of benzidine is 14.8gL -1 The solution. Weigh 1.421 g of biphenyltetracarboxylic dianhydride and add it into the above beaker to continue stirring for 10 h to obtain polyimide. Wherein, the mass of biphenyltetracarboxylic dianhydride is 1.6 times that of benzidine.

[0048] Crystallization process: Transfer the polyimide in the beaker to a reaction kettle with a polytetrafluoroethylene liner for crystallization at 170°C for 10 hours, filter the yellow precipitate obtained after crystallization in a vacuum filter, and use methyl formaldehyde The amide was washed twice and then washed once with absolute ethanol, and then placed in a vacuum oven at 60...

Embodiment 3

[0051] Porous carbon flowers are prepared by template-free method (solvothermal method):

[0052] Synthesize polyimide first: Measure methyl formamide in a beaker with a graduated cylinder, then add 0.89g of benzidine, put in a magnet and increase the speed to stir until the benzidine is completely dissolved, and the concentration of benzidine is 14.8gL -1 The solution. Weigh 1.421 g of biphenyltetracarboxylic dianhydride and add it into the above beaker to continue stirring for 10 h to obtain polyimide. Wherein, the mass of biphenyltetracarboxylic dianhydride is 1.6 times that of benzidine.

[0053] Crystallization process: transfer the polyimide in the beaker to a reaction kettle lined with polytetrafluoroethylene for crystallization at 190°C for 10 hours, and suction-filter the yellow precipitate obtained after crystallization in a vacuum filter. The amide was washed twice and then washed once with absolute ethanol, and then placed in a vacuum oven at 60° C. overnight to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com