High strength probe used for optical coherence tomography imaging

An optical coherence tomography, high-strength technology, applied in the direction of diagnosis, application, medical science, etc., can solve the problems of inconvenient clinical application, good mechanical properties, broken or damaged probes, etc., achieve good market prospects, improve mechanical strength, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0020] Embodiment: In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

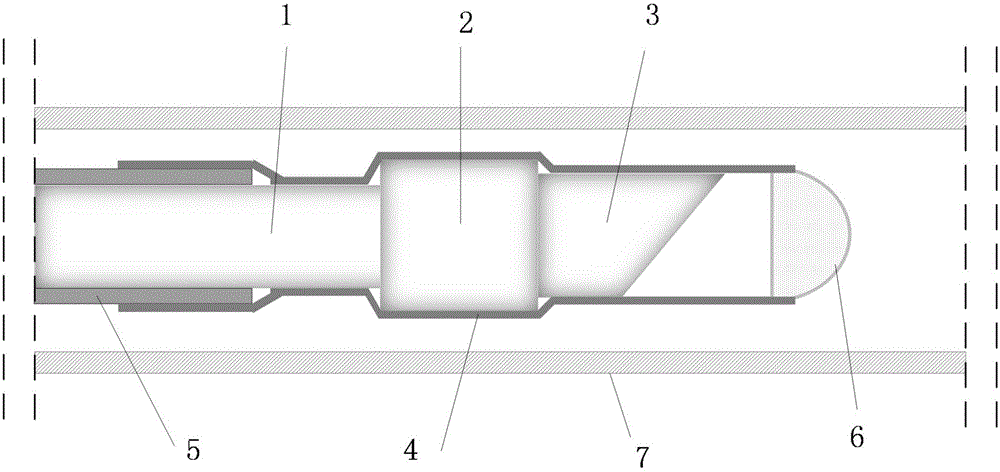

[0021] like figure 1 As shown, the present invention provides a high-intensity probe for optical coherence tomography, including a single-mode optical fiber 1, a self-focusing lens 2, a turning lens 3, a high-scattering rate heat-shrinkable tube 4, a torque cable 5, and a sealing cap 6 And the protective sleeve 7, the single-mode fiber 1, the self-focusing lens 2 and the turning lens 3 are connected together from left to right, the left end of the single-mode fiber 1 is in the hollow torque cable 5, and the high-scattering rate heat shrinkable tube 4 Cover the torque cable 5, single-mode optical fiber 1, self-focusing lens 2 and turning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com