Motor base and motor

A motor seat and seat body technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of low coaxiality of the whole machine, uneven motor air gap, difficult to control noise, etc., to achieve noise control, The effect of weakening the accumulation of shape and position errors and improving the coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

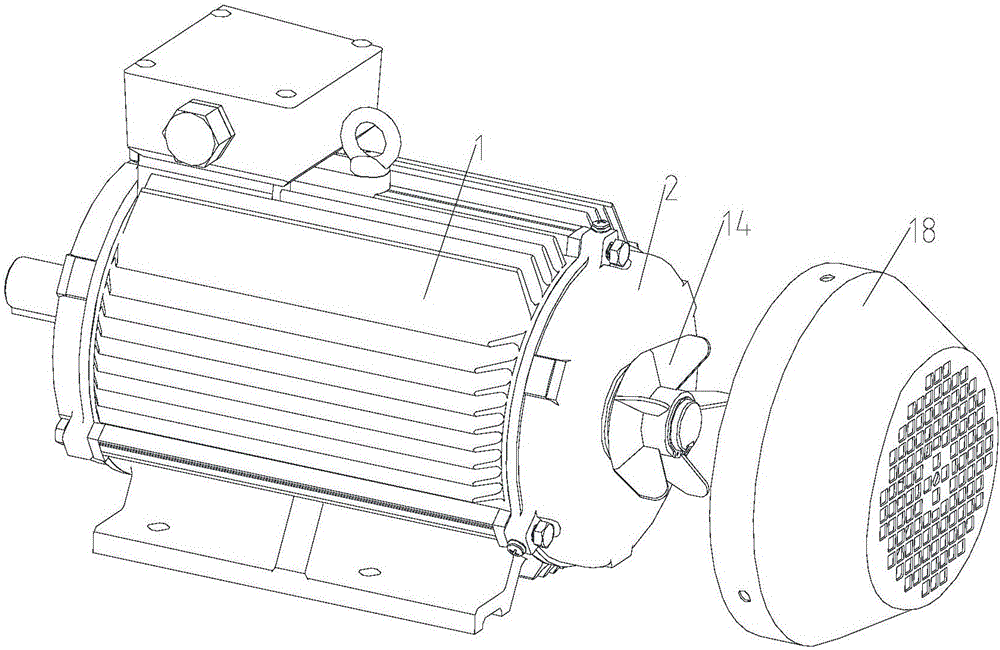

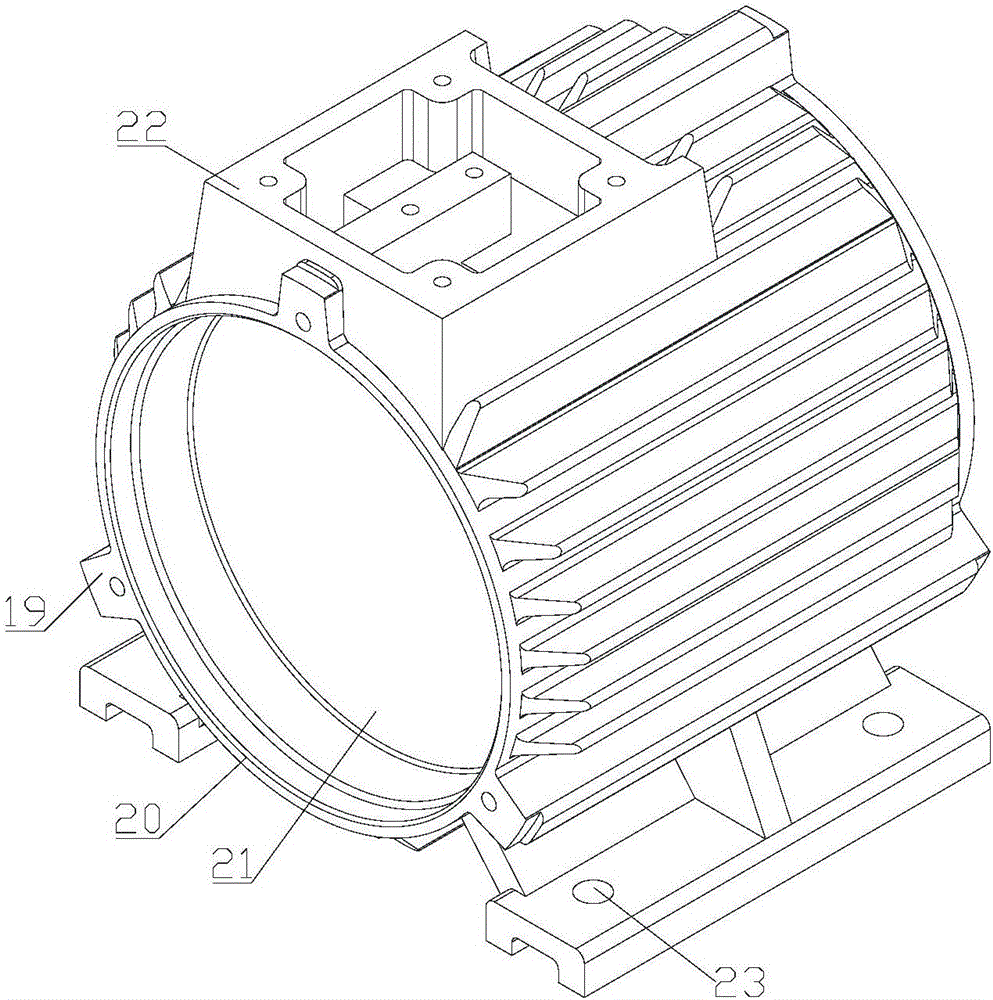

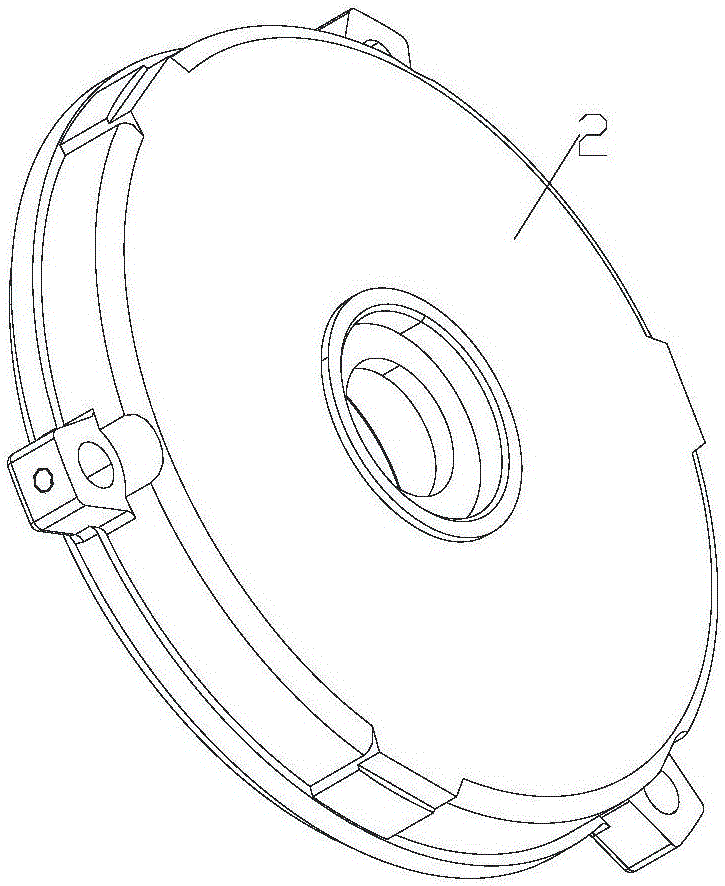

[0034] Please refer to Figure 5 to Figure 12 , The motor base in the present invention includes a base body 1 and an end cover 2, wherein the base body 1 is in a hollow cylindrical shape, the above-mentioned end cover 2 is installed at the first end, and the second end is an opening. More particularly, the seat body 1 and the end cover 2 in the present invention are made in an integrated manner. In the present invention, the end cap 2 can be a front end cap or a rear end cap. Additionally, the opening at the second end allows another end cap to be fitted as in the prior art.

[0035] Preferably, a boss 4 is formed at the transition between the outer surface of the seat body 1 and the end cover 2 . The boss strap 4 is used for fixing the base body by the chuck of the machine tool du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com