Solar battery module for taut-string-type semi-rigid plate

A solar cell and semi-rigid technology, applied in the field of solar cell arrays, can solve the problems of complex manufacturing process and high cost, and achieve the effects of easy control of glue amount, easy defoaming and control of product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

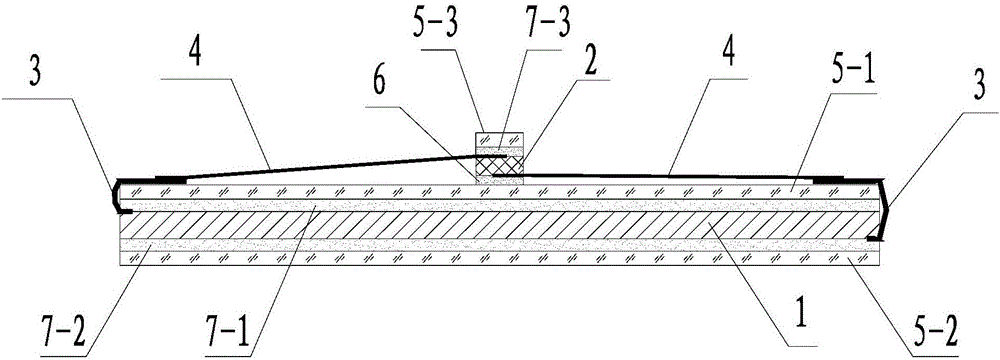

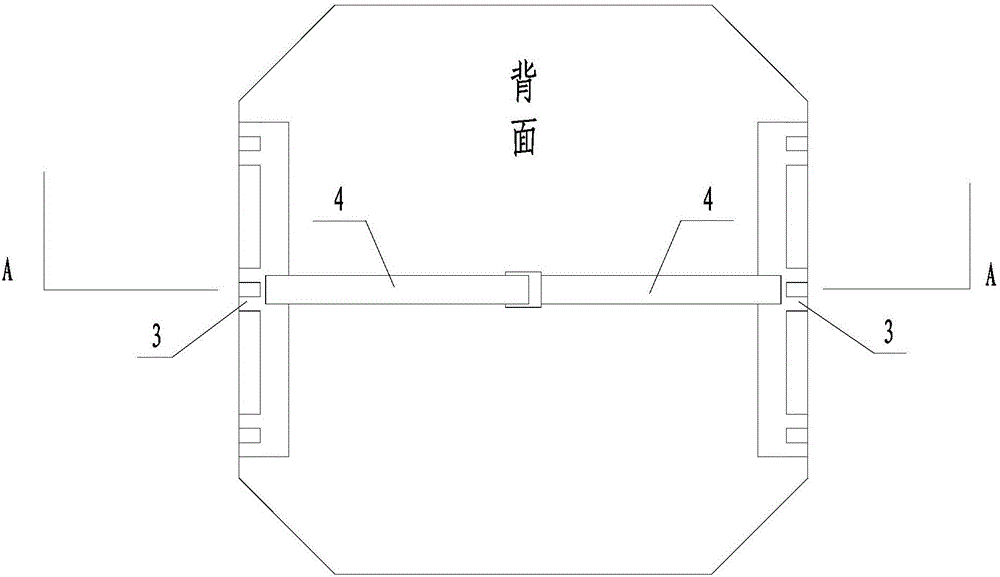

[0027] See attached figure 1 and figure 2 , solar cell upper and lower electrode interconnection sheet welding and upper and lower surface cover sheet bonding to form a solar cell with cover sheet separately, bypass diode positive and negative electrode welding and single-sided glass cover sheet to make a bypass diode with cover sheet separately, and finally Then paste the two together and realize electrical connection.

[0028] 1. Fabrication of solar cells with cover sheet

[0029] Taking a solar cell with a conventional structure as an example, the side with grid lines is called the front of the solar cell, the main grid on one side is called the upper electrode, and the other side is called the back of the solar cell. Generally, the entire surface is vapor-deposited with metal electrodes, called the lower electrode. electrode.

[0030] Welding of upper and lower electrodes: Take 1 piece of large-area solar cell, 1 piece of upper and lower electrode interconnection piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com