Detection device and detection method for technical performances of engineering vehicle

A technology for technical performance and engineering vehicles, which is applied in the field of technical performance testing devices for engineering vehicles, can solve the problems of single performance testing state mode and complicated debugging, and achieves the effects of good practical significance, easy operation and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

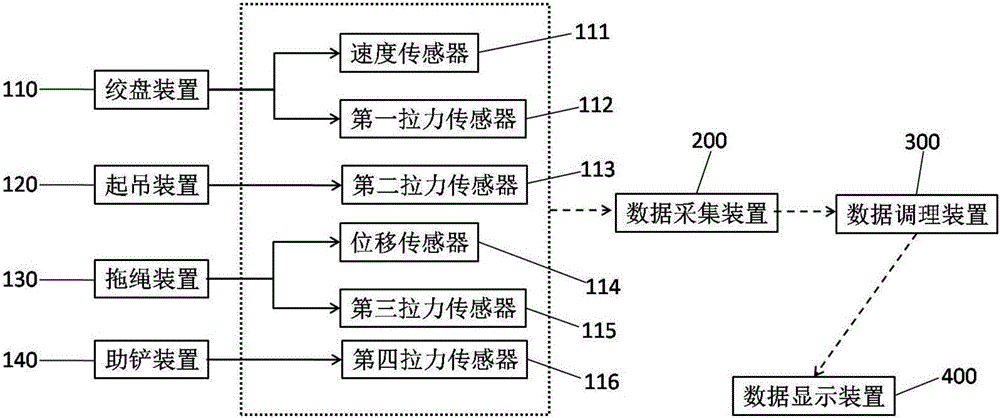

[0037] Such as figure 1 As shown, the present invention provides a technical performance detection device for engineering vehicles, the main structure of which includes: a data monitoring sensor, a data acquisition device 200, a data conditioning device 300, and a data display device 400; wherein, the speed sensor 111 is installed on the winch The drum of the device 110 is used to monitor the retracting and releasing rope speed of the winch device 110. The first tension sensor 112 is installed on the winch device 110 for monitoring the pulling force of the retracting and releasing rope of the winch device 110. The second tension sensor 121 is installed on the winch device 110. On the hoisting device 120, it is used to monitor the hoisting tension of the hoisting device 120. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com