Quality inspection method applied to welding position of connecting column and plate

A technology for welding parts and quality inspection, which is applied to welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as design quality inspection methods, and achieve the effect of simple inspection and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

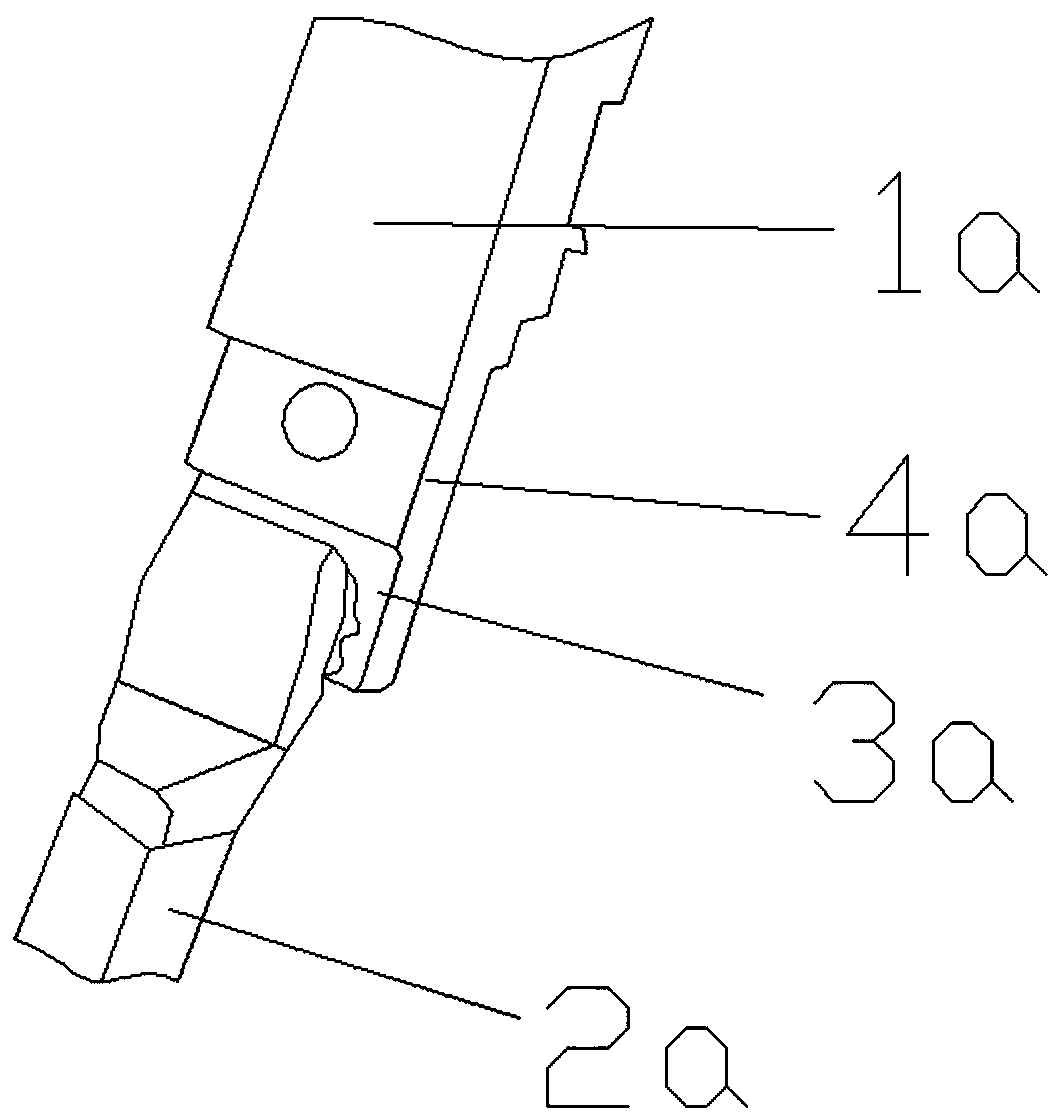

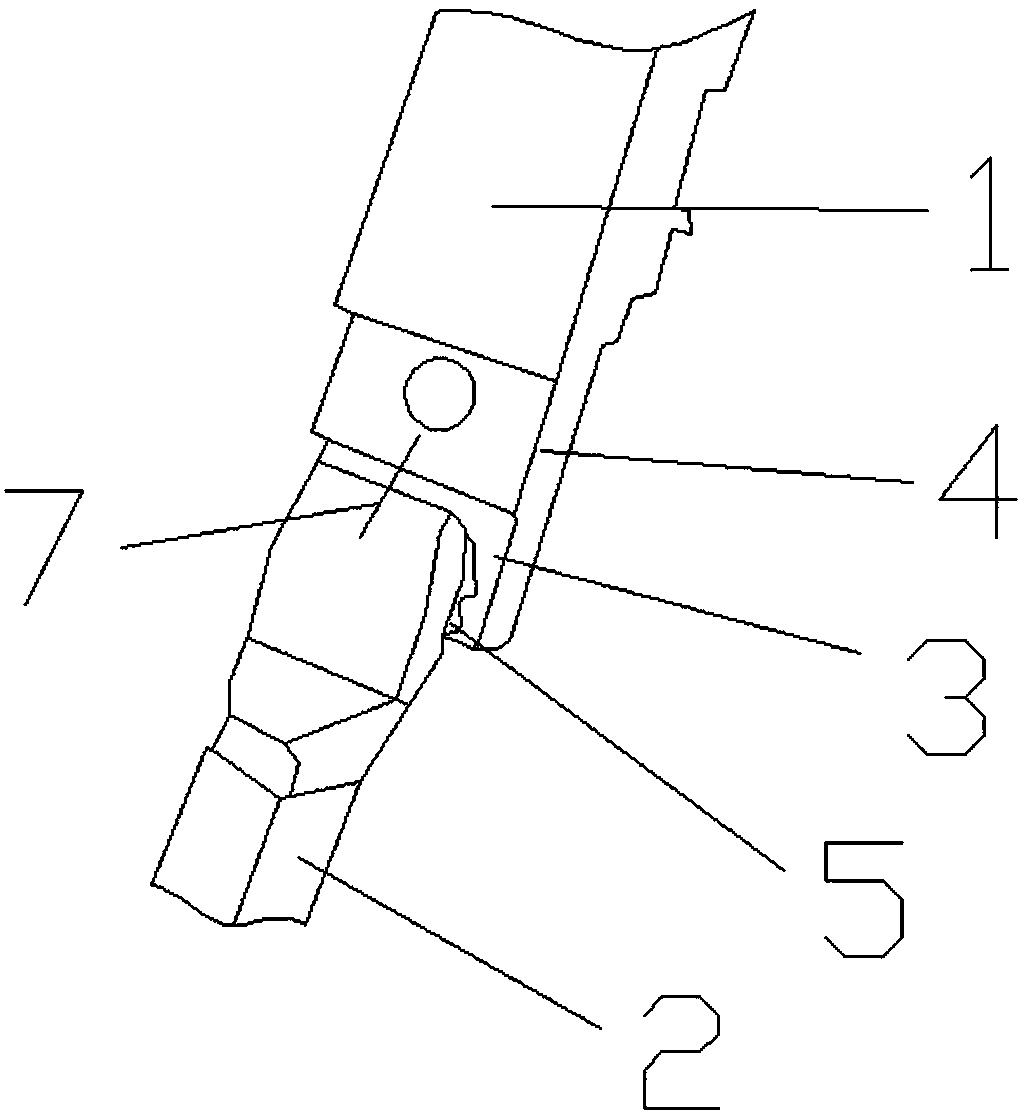

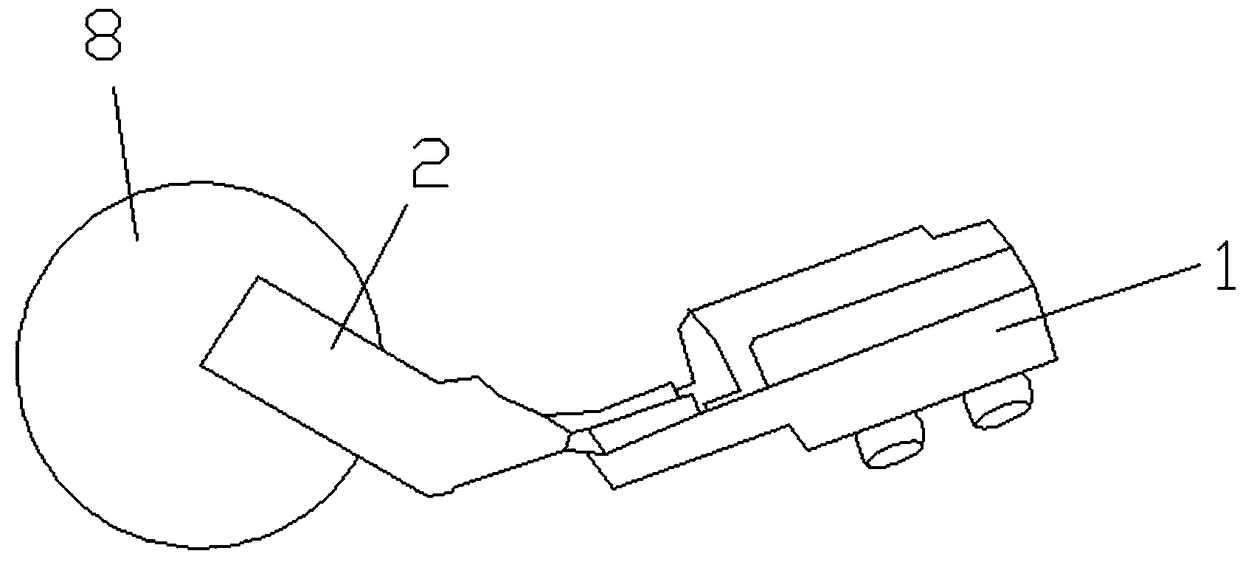

[0029] A quality inspection method applied to the welded part of a connecting column and a plate, wherein one side of the welding end 4 of the connecting column 1 is thinned along the thickness direction to form a stepped surface 3 against the lower surface of the plate 2 , the lower surface of the plate 2 is welded on the step surface 3 of the welding end 4 of the connecting column 1, and the width of the plate 2 is smaller than the width of the step surface 3 of the connecting column 1. In this embodiment, the connecting column 1 It is the current copper column of the ammeter, and the plate part 2 is a red copper sheet, and the method comprises the following steps:

[0030] (1) Appearance inspection of welded parts: judge whether the following conditions are met at the same time:

[0031] a. Solder 5 overflows on at least one side of the board 2;

[0032] b. There is no crack 6 on the connecting column 1 and / or the side opposite to the welding surface on the plate 2 or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com