Seal liner and elastic net pipe

A sealing gasket and elastic technology, applied in the field of sealing gasket, can solve problems such as difficulty in insertion, achieve the effects of reducing friction, simplifying production, and reducing the generation of glass fiber debris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

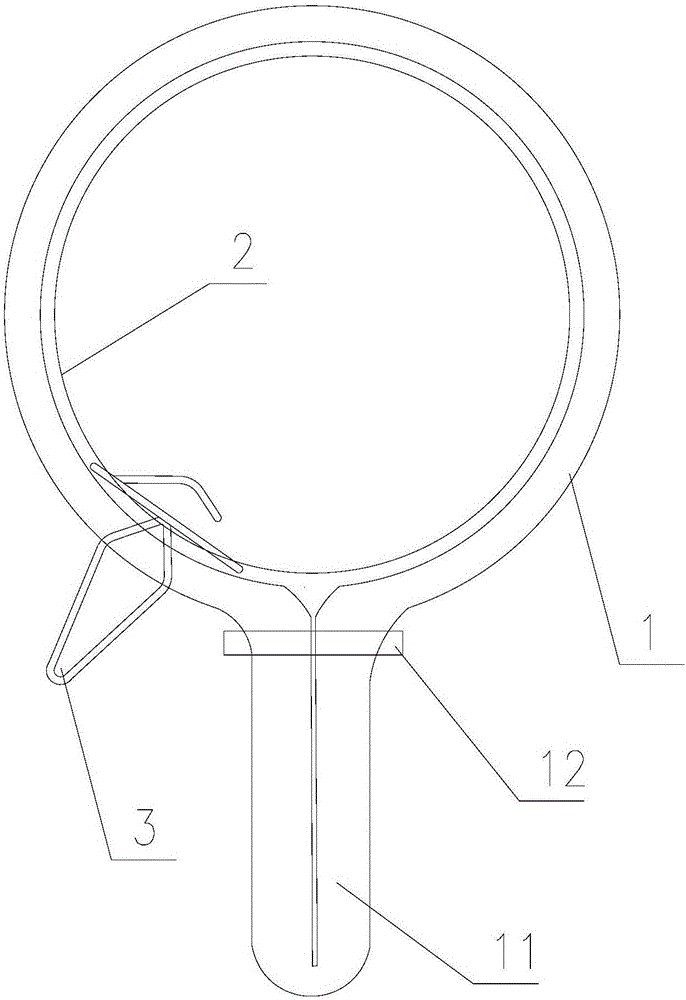

[0025] See figure 1 , 2 and 5, this embodiment includes a glass fiber tube 1, an elastic net tube 2 made of stainless steel wire (0.1 mm in diameter) and a metal hook 3.

[0026] The outer wall of the glass fiber tube 1 is provided with an extension part 11 extending radially along the glass fiber tube 1 and integrated with the glass fiber tube 1; the extension part extends axially along the same side of the outer wall of the glass fiber tube 1 at the same time; The inner and outer walls of the glass fiber tube 1 are impregnated with graphite layers. The graphite layer acts as a lubricant, which facilitates the penetration of the elastic mesh into the fiberglass tube, greatly reducing friction, which in turn greatly reduces the generation of glass fiber debris. In addition, for the second production method, the friction is also greatly reduced, thereby greatly reducing the generation of glass fiber debris.

[0027] Such as Figure 6 , the elastic network tube 2 is made of ...

Embodiment 2

[0036] See image 3 and 4 , on the basis of embodiment 1, there are the following modifications in this embodiment:

[0037] The fiberglass tube 1 and the extension part 11 are braided and formed at one time, and the fiberglass tube 1 and the extension part 11 are tubular, and the extension part 11 is crushed during use. When the glass fiber tube 1 is flattened, the width of the extension part (11) is 1 / 5 to 3 / 5 of the width of the glass fiber tube (1).

Embodiment 3

[0039] For the elastic network pipe 2 of the above-mentioned embodiment 1 or 2, when weaving, the ends of the metal wires move along the spiral, and make the arc-shaped heads of the Ω bodies in the upper layer pass through the heads of the corresponding Ω bodies in the lower layer as a whole. , and so on, forming the elastic network pipe 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com