Pile foundation reinforcement cage spiral reinforcement machining and binding integrated construction method

A construction method and steel cage technology, which is applied in the direction of foundation structure engineering, sheet pile walls, and building materials processing, can solve the problems of cumbersome procedures, more manpower and time investment, etc., to ensure the quality of the project and reduce the number of construction personnel , tight bite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

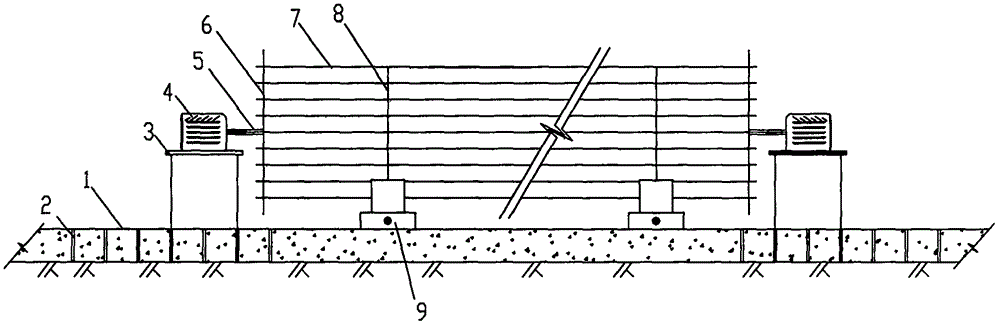

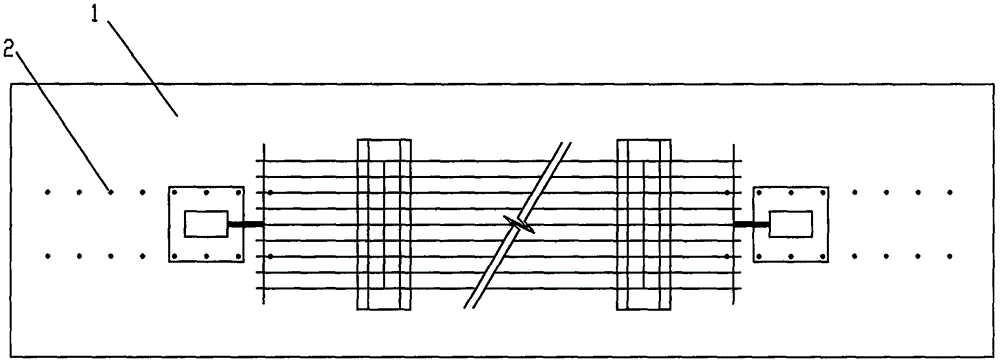

[0018] With reference to accompanying drawing, method of the present invention is as follows:

[0019] 1) First build the construction site. The construction site is a rectangular hardened ground 1. On the hardened ground, two rows of pre-embedded steel casings 2 arranged at equal intervals along the length direction of the construction site are arranged, and the two rows of pre-embedded steel casings are parallel to each other;

[0020] 2) making the reinforcement cage skeleton, the reinforcement cage skeleton including the reinforcement cage main bars 7 distributed at equal intervals and parallel to each other on the same circumference, and the reinforcement cage reinforcing bars 8 surrounding the reinforcement cage main bars and welded with the reinforcement cage main bars;

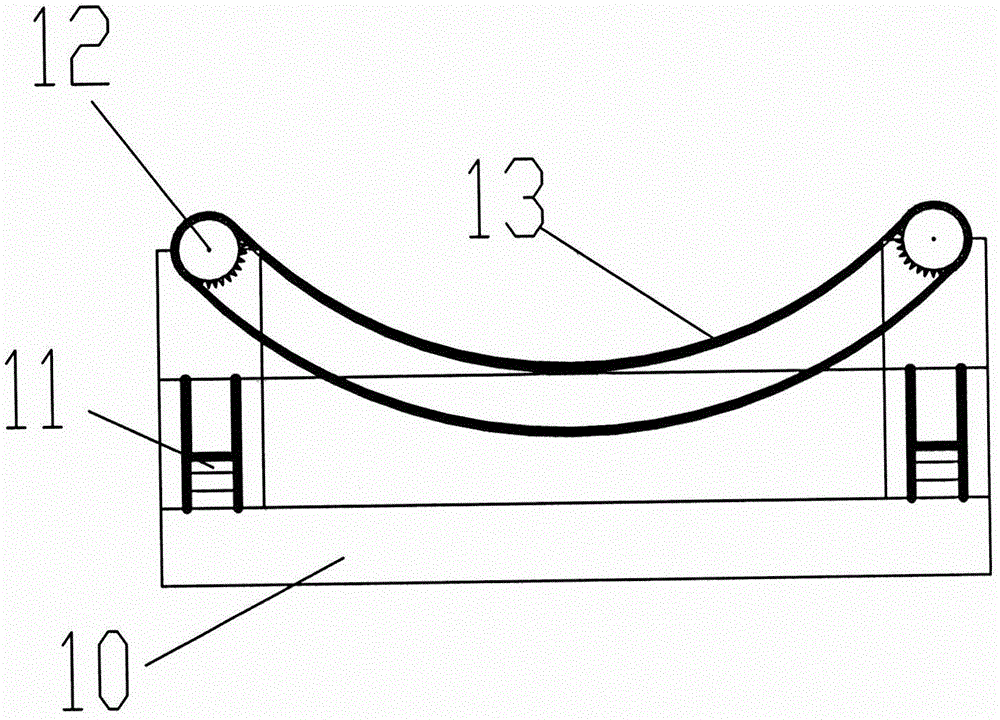

[0021] 3) According to the length of the steel cage skeleton, on the construction site, the center line between the two rows of embedded steel casings is the central axis, and the chain jack support sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com