Nailing stabilizing system

A stabilizing system and nail-feeding technology, which is applied in the direction of wrench, screwdriver, manufacturing tools, etc., can solve the problem that the mounting seat is easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

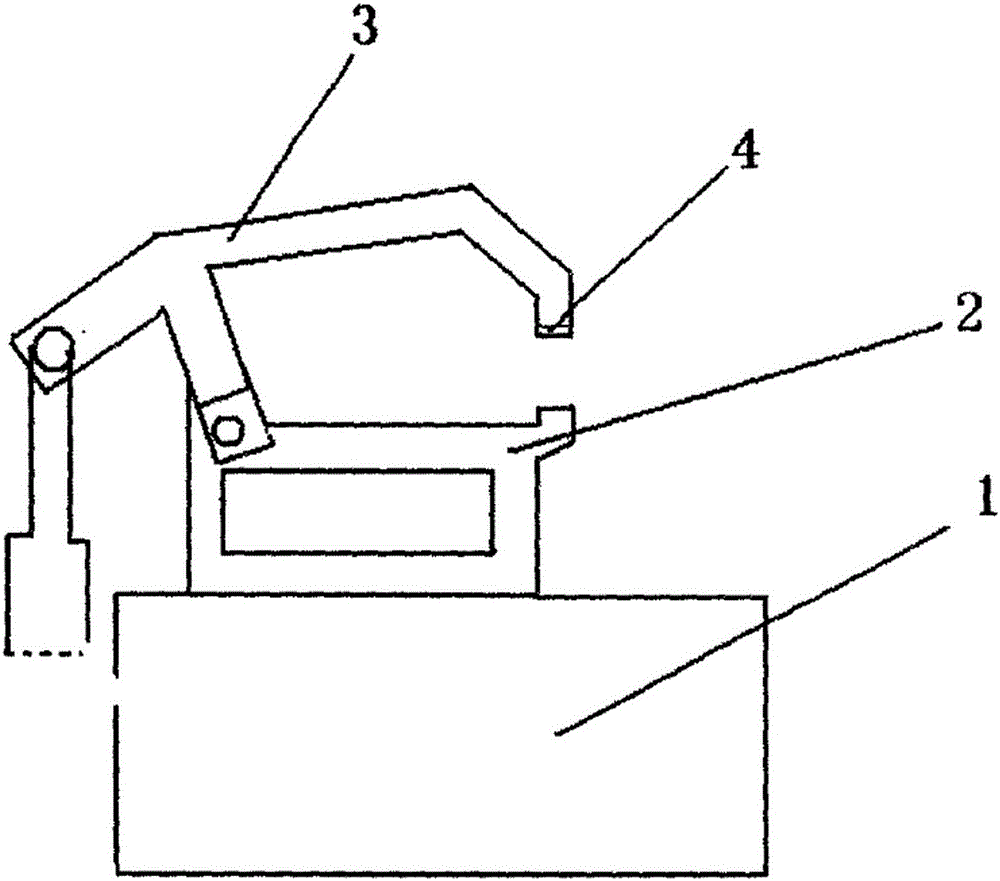

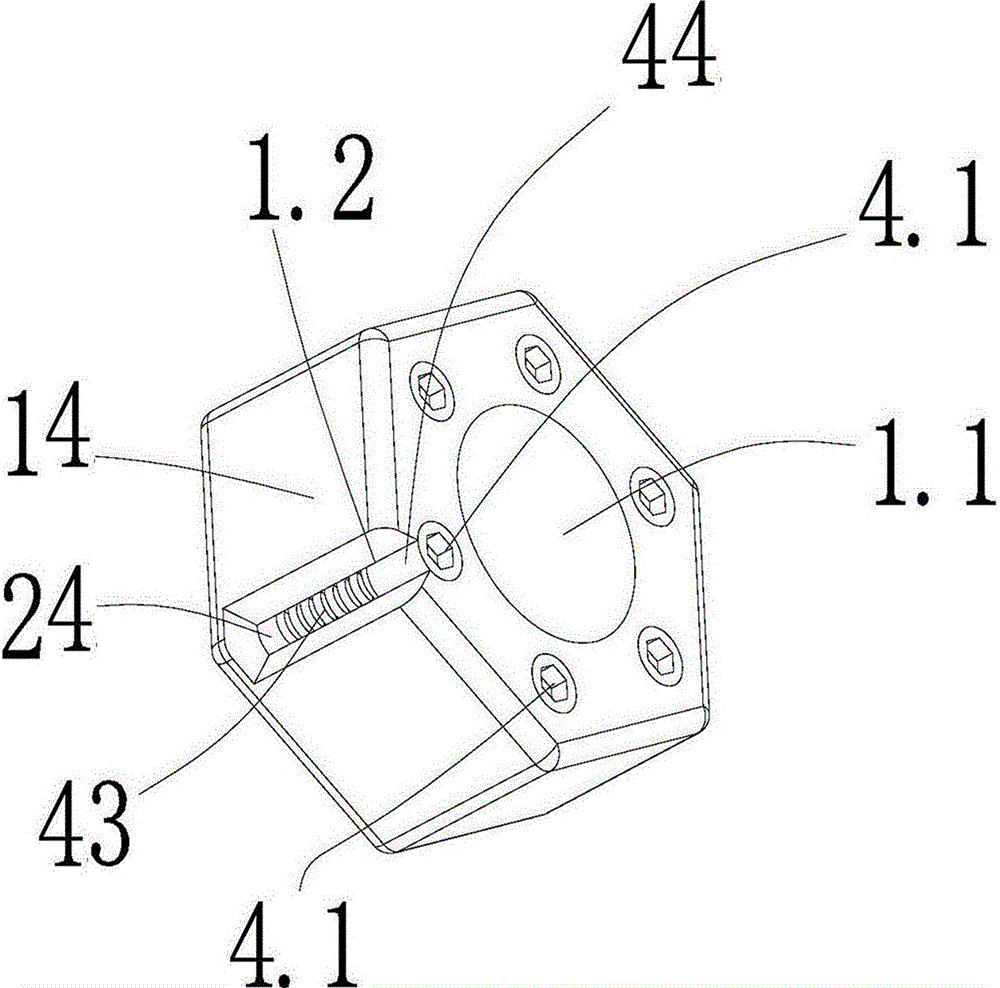

[0012] Such as figure 1 , 2 As shown, the nailing stabilization system includes a load-bearing tool 1, and a striker is added to the outer end of the original load-bearing tool 1, and the striker and the load-bearing tool 1 are connected by a bolt assembly.

[0013] The percussion device is composed of a mounting base 2 and a marking hammer 3; the marking hammer 3 and the mounting base 2 are connected by a rotating shaft, and the marking hammer 3 can rotate relative to the mounting base 2, to strike;

[0014] One end of the marking hammer 3 is provided with a striking head 4 corresponding to the mounting seat 2, and the other end is connected to the carrying tool 1 through a connecting rod device, and knocks on the mounting seat 2 according to the power source input by the carrying tool 1. Hitting, the middle part is the connection between the hammer and the mounting s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com