Intelligent insulating type asphalt concrete mixing station

A technology for asphalt concrete and mixing plants, which can be used in roads, buildings, road repairs, etc., and can solve problems such as rapid heat dissipation and temperature loss of hot materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

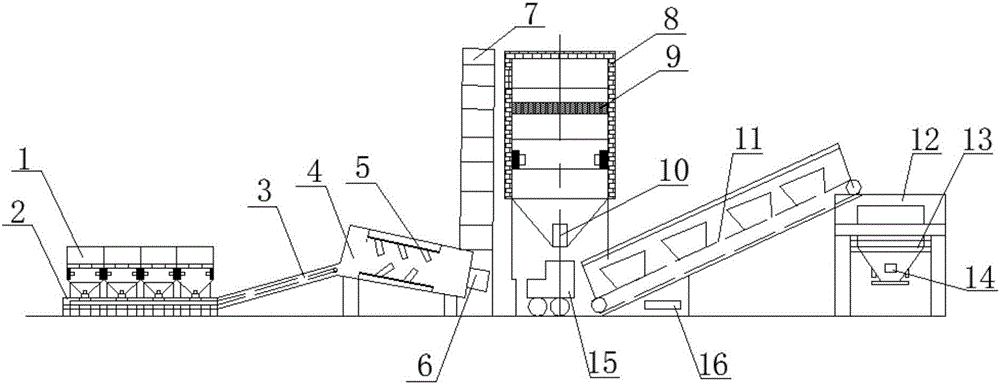

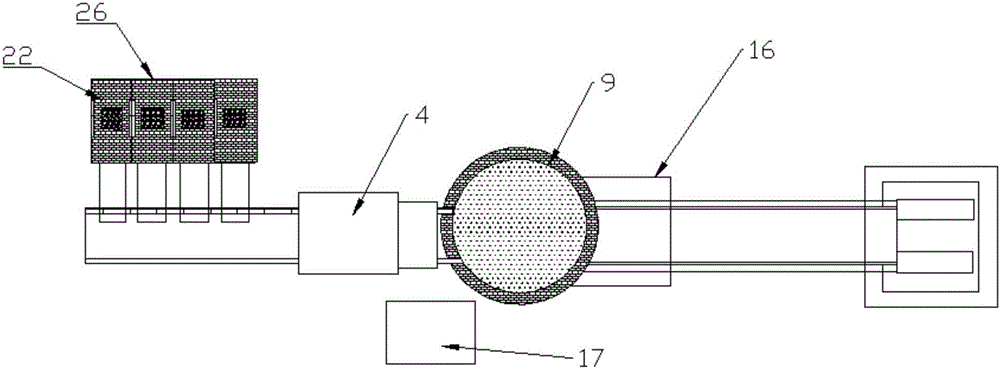

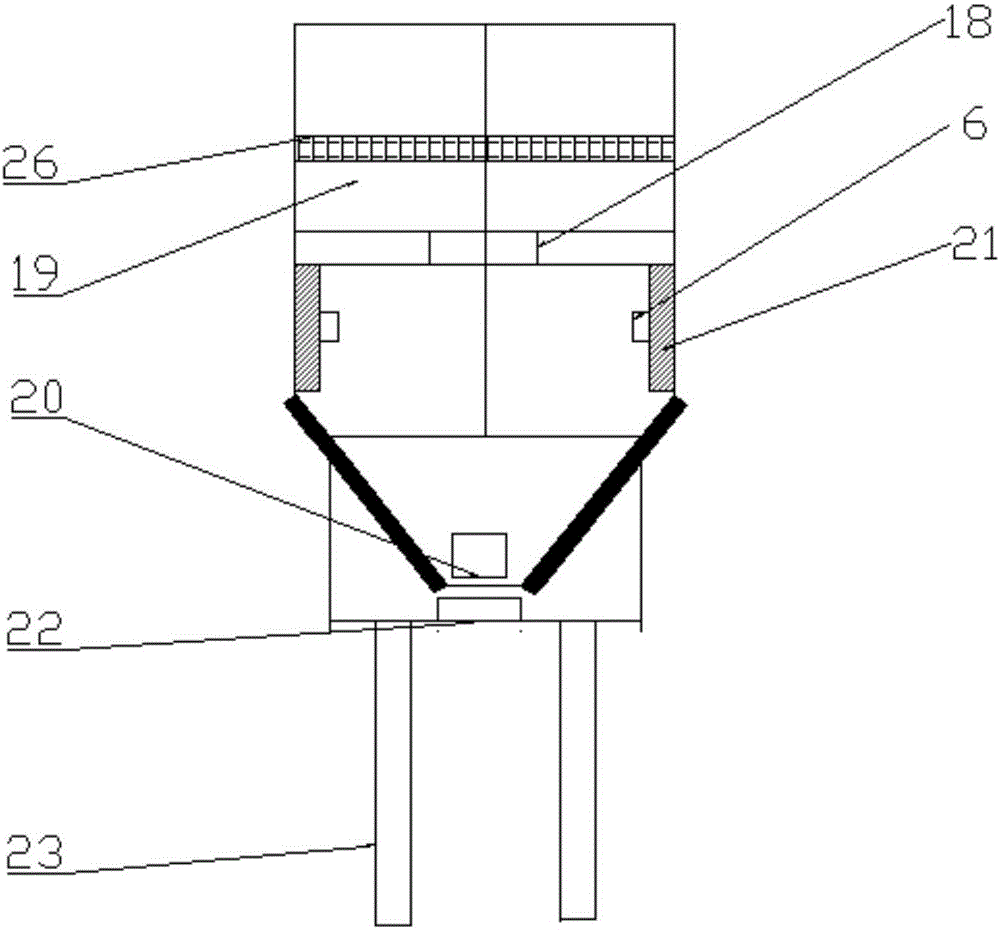

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0029] see Figure 1 to Figure 4 , an intelligent thermal insulation asphalt concrete mixing plant, including several aggregate bins 1 capable of heating the aggregate, the outlet of the aggregate bin 1 is connected with a heat preservation barrel 2, and the bottom of the aggregate bin 1 is provided with a bin support frame 23 , the bottom of the heat preservation barrel 2 is provided with a heat preservation barrel support frame 25, and the heat preservation barrel 2 is provided with a heat material belt conveyor 3 for conveying the heat material to the heating and stirring drum 4, and the heating and stirring drum 4 is provided with a stirring blade 5, heating and stirring The outlet of the drum 4 is connected to the vertical mixing drum through the lifting device 7, the bottom of the vertical mixing drum is provided with a discharge port 10, the aggregate bin 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com