Titanium dioxide nanotube with good osteogenesis promoting function and preparation method thereof

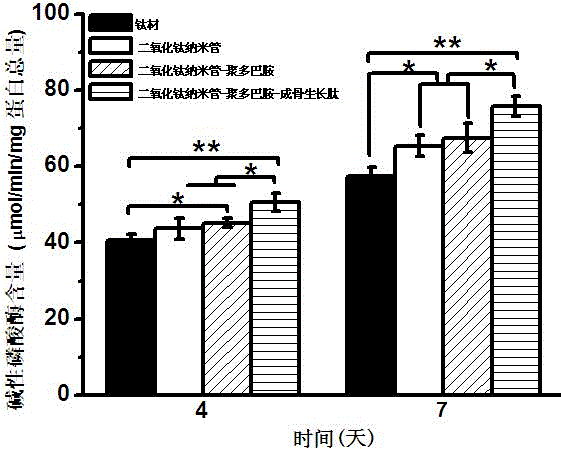

A technology of titanium dioxide and nanotubes, applied in coatings, medical science, prostheses, etc., can solve the problems of poor integration between titanium-based implants and surrounding natural bone tissue, lack of potential for inducing osteogenesis, etc., and achieve good application prospects. Short cycle, effect of promoting osteogenic differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

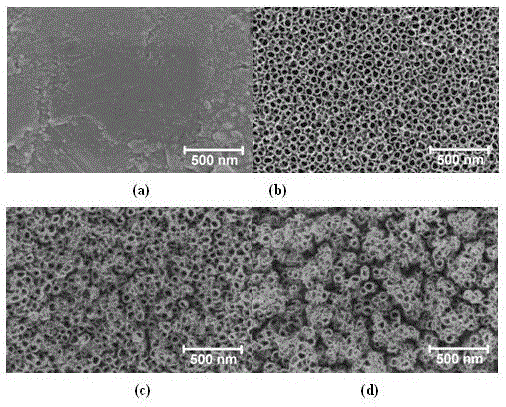

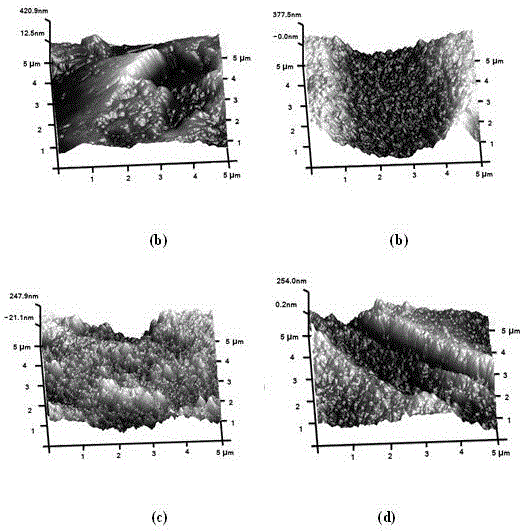

[0022] Embodiment 1. Preparation of titanium dioxide nanotubes with good bone-promoting effect

[0023] a. Cut the titanium material into 1 cm×1 cm titanium sheet, ultrasonically clean it with acetone, absolute ethanol and double distilled water for 20 minutes, and dry it in an oven at 37°C for later use;

[0024] b. Use the titanium sheet prepared in step a as the anode, the platinum sheet as the cathode, and the 0.27 mol / L ammonium fluoride solution prepared with a volume ratio of glycerol and double-distilled water of 1 to 1 as the electrolyte. After electrolysis under voltage for 1 h, the oxidized titanium sheet was ultrasonically cleaned for 2 min, dried, and finally placed in a muffle furnace and heated at 400 °C for 2 h to obtain titanium dioxide nanotubes with a diameter of 30 nm;

[0025] c. Prepare a dopamine hydrochloride solution with a concentration of 2 mg / mL using a 10 mmol / L tris buffer solution, and adjust the pH to 8.5, immerse the titanium dioxide nanotubes ...

Embodiment 2

[0027] Example 2. Preparation of Titanium Dioxide Nanotubes with Good Osteogenesis

[0028] a. Cut the titanium material into 1 cm×1 cm titanium sheet, ultrasonically clean it with acetone, absolute ethanol and double distilled water for 20 minutes, and dry it in an oven at 37°C for later use;

[0029] b, with the titanium sheet prepared in step a as the anode, the platinum sheet as the cathode, and the 0.27 mol / L ammonium fluoride solution prepared with a volume ratio of glycerol and double-distilled water of 1 to 1 as the electrolyte, at a constant temperature of 20 V After electrolysis under voltage for 1 h, the oxidized titanium sheet was ultrasonically cleaned for 2 min, dried, and finally placed in a muffle furnace and heated at 400 °C for 2 h to obtain titanium dioxide nanotubes with a diameter of 70 nm;

[0030] c. Using 10 mmol / L Tris buffer to prepare a dopamine hydrochloride solution with a concentration of 2 mg / mL, and adjusting the pH to 8.5, immersing the titaniu...

Embodiment 3

[0037] Example 3. Preparation of Titanium Dioxide Nanotubes with Good Osteogenesis

[0038]a. Cut the titanium material into 1 cm×1 cm titanium sheet, ultrasonically clean it with acetone, absolute ethanol and double distilled water for 20 minutes, and dry it in an oven at 37°C for later use;

[0039] b, using the titanium sheet prepared in step a as the anode, the platinum sheet as the cathode, and the 0.27 mol / L ammonium fluoride solution prepared with a volume ratio of glycerol and double-distilled water of 1 to 1 as the electrolyte, at a constant temperature of 30 V After electrolysis under voltage for 1 h, the oxidized titanium sheet was ultrasonically cleaned for 2 min, dried, and finally placed in a muffle furnace and heated at 400 °C for 2 h to prepare titanium dioxide nanotubes with a diameter of 100 nm;

[0040] c. Prepare a dopamine hydrochloride solution with a concentration of 2 mg / mL using a 10 mmol / L tris buffer solution, and adjust the pH to 8.5, immerse the ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com