Deep-cooling surface-layer continuous-rolling preparation method for gradient strip

A strip and surface layer technology, which is applied in the field of metal material rolling, can solve the problem that it cannot be used to prepare strips, etc., and achieve the effect of improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

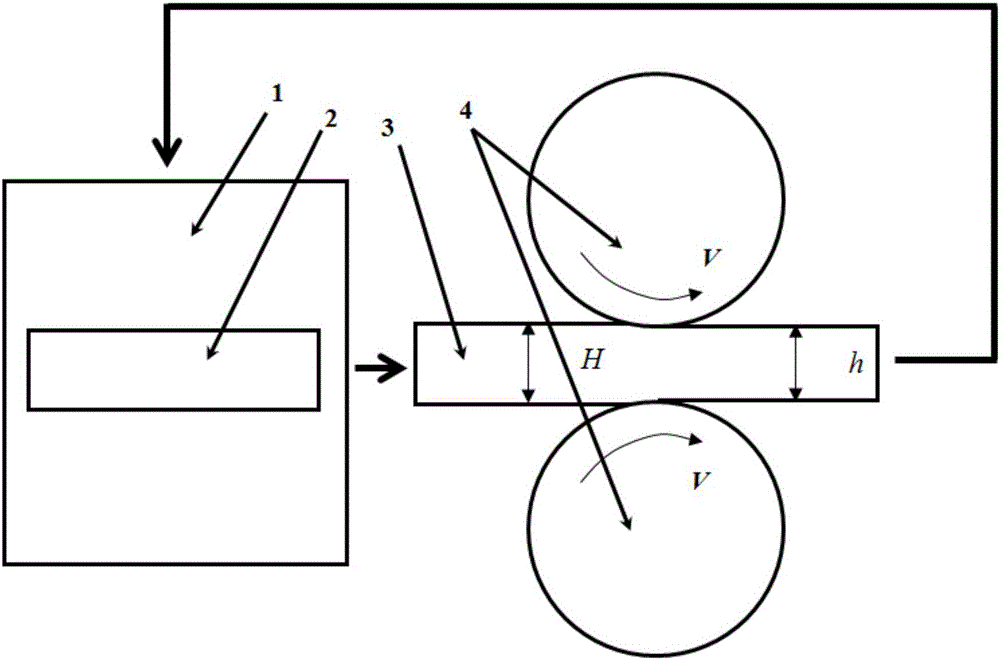

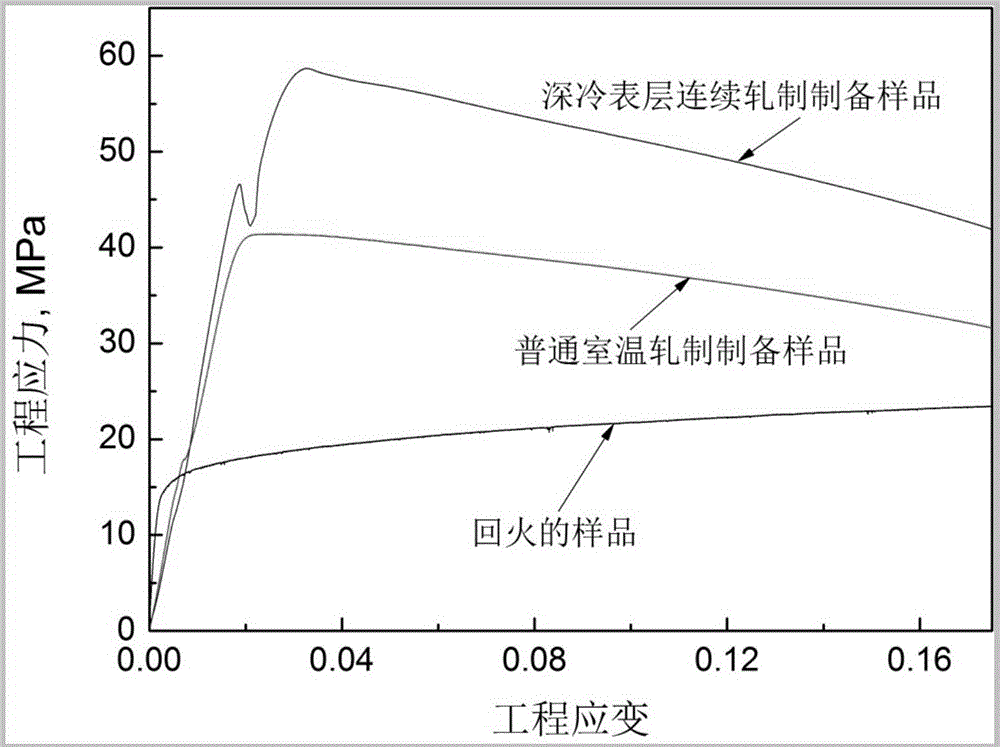

[0017] The main principle of the invention is to use the plastic deformation of the surface of the material to promote the refinement of the crystal grains in the surface area, and at the same time, use the ultra-low temperature deformation to suppress the recrystallization of the ultra-fine grains during the plastic deformation, thereby forming a nanostructure on the surface of the material. figure 1 Shown is the flow chart of the continuous rolling preparation of the cryogenic surface layer. Through multi-pass cryogenic surface rolling, the rolled piece forms a strip with a gradient structure, such as figure 1 Shown, the concrete steps of the present invention are as follows:

[0018] The first step: the aluminum or aluminum alloy strip after annealing heat treatment is used as raw material.

[0019] Step 2: Put the strip into the liquid nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com