Double-component external wall heat-insulating putty having water resistance effect and preparation method thereof

An external wall thermal insulation, two-component technology, used in filling slurry and other directions, can solve the problems of less rubber powder, large damage to the wall, low flexibility, etc., to strengthen energy conservation and environmental protection, and improve the waterproof and anti- cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

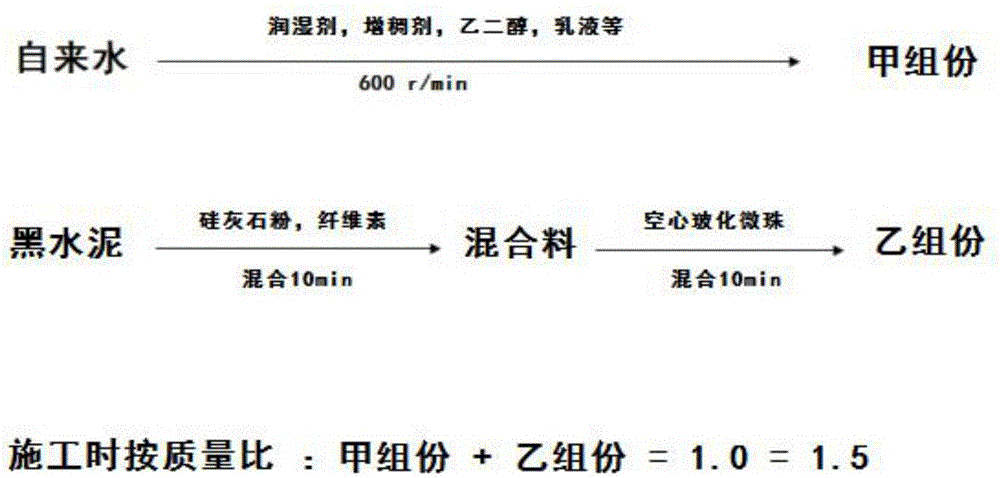

[0020] A two-component external wall thermal insulation putty with waterproof effect is characterized in that it includes component A and component B; component A consists of 10.0-20.0% of water, 30.0-40.0% of emulsion, and 0.1-0.2% of multifunctional additives %, defoamer 0.2-0.5%, wetting agent 0.2-0.4%, ethylene glycol 1.0-1.5%, film-forming aid 1.5-2.0%, thickener 0.2-0.4%; component B is made of 425 Black cement 40.0-55.0%, hollow vitrified microspheres 40.0-50.0%, water-repellent agent 2.0-3.0%, wollastonite powder 3.0-6.0%, cellulose 0.6-1.0%, rubber powder 6.0-8.0%, wood fiber 0.4 -0.6%, made of polypropylene fiber 0.4-0.6%; when used, components A and B are mixed evenly in a ratio of 1:1.2.

[0021] In this example, the emulsion used for component A is an elastic waterproof emulsion with a glass transition temperature of -15°C. Under the condition of maintaining excellent elasticity, it can effectively combine with cement to improve the waterproof function of the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com