Blue-light-resistant resin and preparation method thereof

An anti-blue light and resin technology, applied in optics, optical components, instruments, etc., can solve the problems of low output and high cost of lenses, and achieve the effects of prolonging service life, uniform distribution, and delaying photoaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

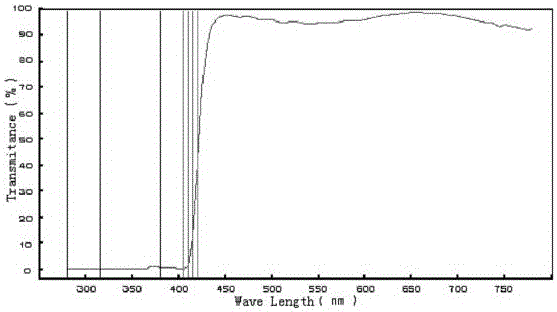

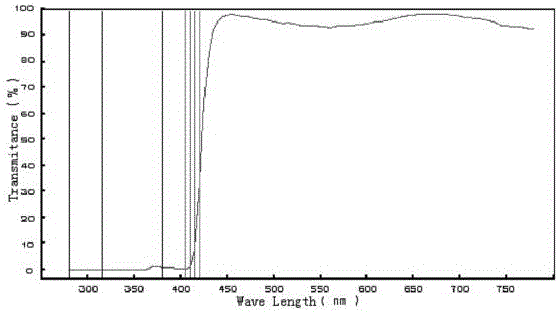

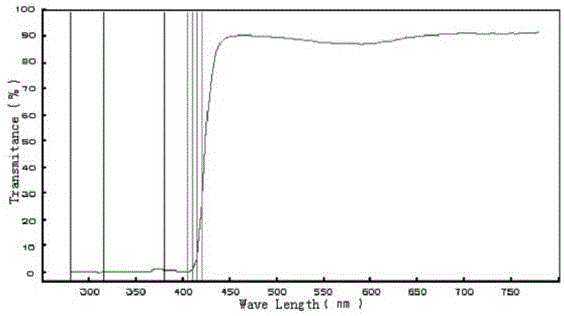

Image

Examples

Embodiment 1

[0033] A kind of anti-blue light resin, its raw material comprises:

[0034] Mixed resin: Trihydroxymethylpropane trimethacrylate 1000g, pentaerythritol triacrylate 1000g, 2-methyl-2-octadecyl acrylate 2500g, polyethylene glycol dimethacrylate 4000g, 2-acrylic acid Lauryl ester 1500g;

[0035] Organic solvent: styrene 2000g;

[0036] Light stabilizer: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate 15g;

[0037] Blue light absorber: 35 g of 2-hydroxy-4-n-octyloxybenzophenone.

[0038] The preparation method of the anti-blue light resin of the present embodiment comprises the following steps:

[0039] 1) Add each component in the mixed resin into the mixing container according to the formula, and stir at room temperature for 100 minutes to make a mixed resin;

[0040] 2) Add the light stabilizer into the organic solvent, stir at room temperature until it is fully dissolved, then add the blue light absorber, and stir again at room temperature until it is fully dissolved;

...

Embodiment 2

[0044] A kind of anti-blue light resin, its raw material comprises:

[0045] Mixed resin: 2000g trihydroxymethylpropane trimethacrylate, 2000g pentaerythritol triacrylate, 2500g 2-methyl-2-octadecyl acrylate, 2500g polyethylene glycol dimethacrylate, 2-acrylic acid Lauryl ester 1000g;

[0046] Organic solvent: ethanol 2500g;

[0047]Light stabilizer: bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate 25g, polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl -1-piperidine ethanol) ester 25g;

[0048] Blue light absorber: 25g of 2-hydroxy-4-n-octyloxybenzophenone, 25g of 2,2'-dihydroxy-4,4'-dimethoxybenzophenone.

[0049] The preparation method of the anti-blue light resin of the present embodiment comprises the following steps:

[0050] 1) Put each component in the mixed resin into the mixing container according to the formula, and stir at room temperature for 110 minutes to make a mixed resin;

[0051] 2) Add the light stabilizer into the organic solvent, stir at room temperatur...

Embodiment 3

[0055] A kind of anti-blue light resin, its raw material comprises:

[0056] Mixed resin: Trihydroxymethylpropane trimethacrylate 1500g, pentaerythritol triacrylate 1500g, 2-methyl-2-octadecyl acrylate 2000g, polyethylene glycol dimethacrylate 3000g, 2-acrylic acid Lauryl ester 2000g;

[0057] Organic solvent: acetone 2250g;

[0058] Light stabilizer: 20g of 4-benzoyloxy-2,2,6,6-tetramethylpiperidine, polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1- Piperidine ethanol) ester 20g;

[0059] Blue light absorber: 150 g of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole.

[0060] The preparation method of the anti-blue light resin of the present embodiment comprises the following steps:

[0061] 1) Put each component in the mixed resin into the mixing container according to the formula, and stir at room temperature for 120 minutes to make a mixed resin;

[0062] 2) Add the light stabilizer into the organic solvent, stir at room temperature until it is fully dissolved, then add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com