Extraction method of anthocyanin

An extraction method and anthocyanin technology, applied in the direction of organic chemistry, can solve the problems of poor product quality and low stability, and achieve the effects of preventing oxidation, product safety and stability, and improving extraction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

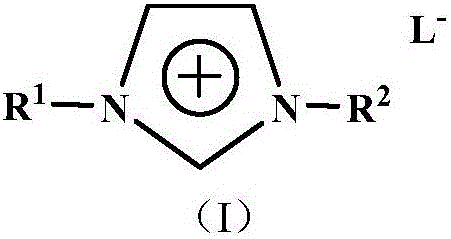

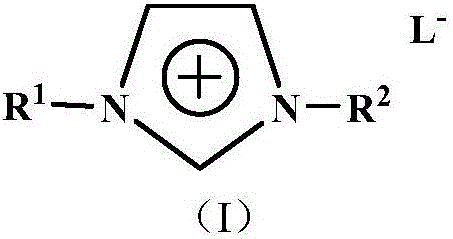

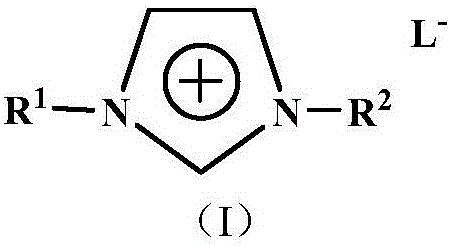

Image

Examples

Embodiment 1

[0029] Take 100Kg of the original fruit of Indigo indigo, add 3Kg of sulfur dioxide, add 5Kg of 30% hydrochloric acid, pulverize, ferment naturally, add 1Kg of cellulase, 1Kg of amylase, 1Kg of lipase for enzymolysis, and filter to obtain the enzymatic hydrolyzate of Indigo indigo. Slowly add the indigo enzymatic hydrolyzate to the D-101 macroporous resin column, wash with 60% ethanol solution, and concentrate the washing liquid under reduced pressure until there is no ethanol smell, adjust the pH to 9, centrifuge, and take the clear The liquid is the indigo fruit extract. Use deionized water to adjust the mass concentration of anthocyanins in the indigo fruit extract to 1.2 mg / mL.

Embodiment 2

[0031] Take 100Kg of the original fruit of Cedarwood, add 1Kg of sulfur dioxide, add 10Kg of 30% hydrochloric acid, pulverize it, ferment naturally, add 5Kg of compound pectinase for enzymolysis, and filter to obtain the enzymatic hydrolyzate of Cedarwood. Slowly add the enzymatic hydrolyzate of edulis to AB-8 macroporous resin column, wash with 90% ethanol solution, and concentrate the washing liquid under reduced pressure until there is no ethanol smell, adjust the pH to 9, centrifuge, and take the clear The liquid is the indigo fruit extract. Use deionized water to adjust the mass concentration of anthocyanins in the indigo fruit extract to 1.2 mg / mL.

Embodiment 3

[0033] Take 100Kg of the original fruit of L. indigo, add 5Kg of sulfur dioxide, add 1Kg of 30% hydrochloric acid, pulverize, ferment naturally, add 5Kg of compound pectinase for enzymolysis, and filter to obtain the enzymatic hydrolyzate of L. indigo. Slowly add the enzymatic hydrolyzed solution of edulis to DM301 macroporous resin column, wash with 20% ethanol solution, and concentrate the washing liquid under reduced pressure until there is no ethanol smell, adjust the pH to 9, centrifuge, and take the clear liquid Indigo fruit extract. Use deionized water to adjust the mass concentration of anthocyanins in the indigo fruit extract to 1.2 mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com