Low-permeability substrate and application of substrate in construction of artificial wetland

A low-permeability, matrix technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of large differences in physical and chemical properties of fillers, inconsistent pollutant removal efficiency, microbial film Poor growth and other problems to achieve the effect of solving the decline and blockage of treatment efficiency, improving the efficiency of sewage treatment, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

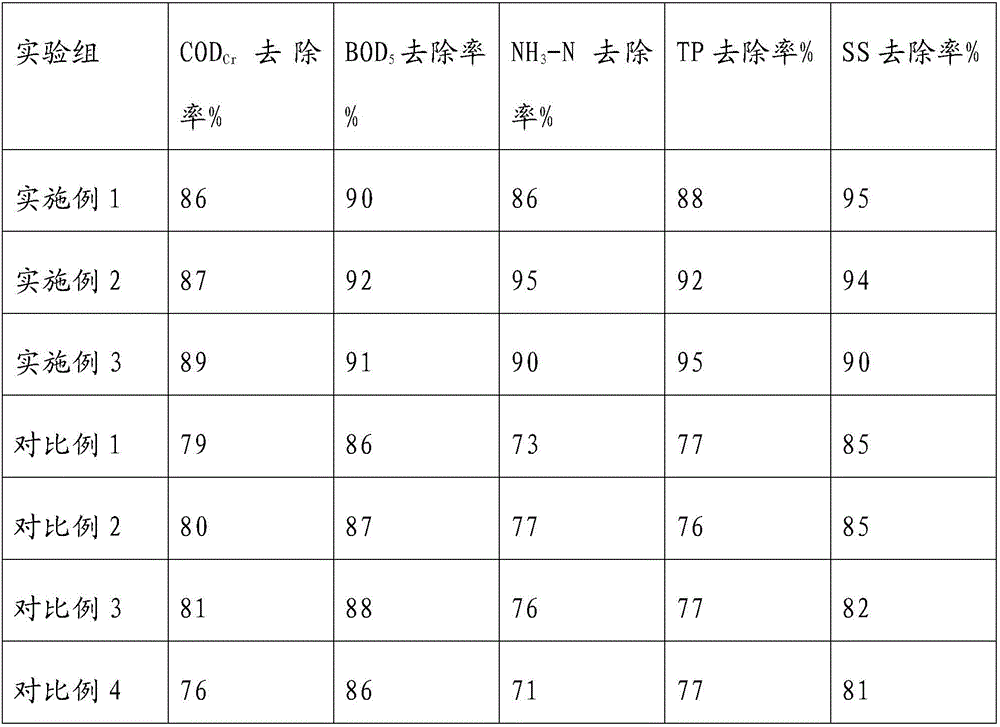

Examples

Embodiment 1

[0015] A low-permeability matrix, including the following fillers in parts by weight and particle size: 2 parts of fine sand with a particle size of less than 0.075mm; 20 parts of coarse sand with a particle size of 0.075mm-0.6mm; coarse sand with a particle size of 0.6mm-2mm 40 parts of sand; 30 parts of crushed stone with a particle size of 2mm-6mm; 6 parts of crushed stone with a particle size of 6-10mm.

[0016] The preparation method of above-mentioned low permeability matrix, comprises the steps:

[0017] (1) Wash the surface of coarse sand and fine sand with 80MPa high-pressure water for 3 minutes, and wash the surface of gravel with 100MPa high-pressure water for 5 minutes;

[0018] (2) Screen the particle size of the filler. According to the parts by weight, select 2 parts of fine sand with a particle size of less than 0.075mm, 20 parts of coarse sand with a particle size of 0.075mm-0.6mm, and 40 parts of coarse sand with a particle size of 0.6mm-2mm. , 30 parts of c...

Embodiment 2

[0021] A low-permeability matrix, including fillers with the following particle sizes: 1 part of fine sand with a particle size of less than 0.075mm; 15 parts of coarse sand with a particle size of 0.075mm-0.6mm; 45 parts of coarse sand with a particle size of 0.6mm-2mm; 35 parts of crushed stone with a particle size of 2mm-6mm; 8 parts of crushed stone with a particle size of 6-10mm.

[0022] The preparation method of above-mentioned low permeability matrix, comprises the steps:

[0023] (1) Clean the surface of coarse sand and fine sand with 80MPa high-pressure water for 3 minutes, and clean the surface of gravel with 90MPa high-pressure water for 5 minutes;

[0024] (2) Screening filler particle size, according to parts by weight, select 1 part of fine sand less than 0.075mm particle size; 15 parts of coarse sand with particle size of 0.075mm-0.6mm; 45 parts of coarse sand with particle size of 0.6mm-2mm; 35 parts of crushed stones with a particle size of 2mm-6mm; 8 parts ...

Embodiment 3

[0027] A low-permeability matrix, including fillers with the following particle sizes: 9 parts of fine sand with a particle size of less than 0.075mm; 15 parts of coarse sand with a particle size of 0.0.75mm-0.6mm; 40 parts of coarse sand with a particle size of 0.6mm-2mm 35 parts of ceramsite with a particle size of 2mm-6mm; 2 parts of pebbles with a particle size of 6-10mm.

[0028] The preparation method of above-mentioned low permeability matrix, comprises the steps:

[0029] (1) Wash the surface of coarse sand and fine sand with 80MPa high-pressure water for 3 minutes, wash the surface of ceramsite with 95MPa high-pressure water for 5 minutes, and wash the surface of pebbles with 85MPa high-pressure water for 5 minutes;

[0030] (2) Screening filler particle size, according to weight parts, select 9 parts of fine sand less than 0.075mm particle size; 15 parts of coarse sand of 0.075mm-0.6mm particle size; 40 parts of coarse sand of 0.6mm-2mm particle size; 35 parts of ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com